Chemical anchors are a type of anchor bolt that relies on chemical bonding. The method fastens steel studs and bolts into a substrate via chemical and resin means. The substrate most frequently consists of masonry or concrete.

In this article you will learn the types of chemical anchors, how they work, installation, the difference between chemical and mechanical anchors, and their applications.

Drilling anchors into a substrate for vessels and tanks might produce strength-ruining splits and cracks. Sometimes chemical resin provides the best option to keep the surface intact. Chemical resin anchors can also employ in weaker brickwork that might disintegrate under sleeve anchors and screw threads.

Types of Chemical Anchors

The type of chemical anchor specified depends on the substrate, desired strength requirements, and curing requirements.

Polyester

These chemical anchors, widely used injection anchoring technology, are simple to use and apply. The dual injectable cartridge fills with two components in varied sizes. It’s a reactive resin that makes a two-component injection mortar.

Unsaturated Polyester

This is the traditional reactive resin for making 2-component injection mortars. It includes both unsaturated polyester resins dissolved in styrene (the original resin type) and unsaturated polyester resins without styrene but with styrene-related monomers as a reactive solvent. The 2-component injection mortars created from these resins are quick and straightforward to use, with little chemical resistance (in alkaline and other media).

Epoxy Acrylate

Epoxy acrylate chemical anchor is a styrene-free epoxy acrylate two-component resin for use in concrete and masonry. This serves as a fast-curing, high-strength resin fixing anchor for extremely high loads and essential fixings, particularly in corrosive or moist situations. Based on styrene-free vinyl ester technology with high reactivity, it is suitable for heavy, high-performance loads, rapid curing, and minimal odor.

Pure Epoxy

Pure Epoxy Standard provides a two-component pure epoxy bonded anchoring system with a 1:1 ratio. Pure epoxy sees use in the most demanding structural applications and rebar connections. As such, it has a very high load-bearing capability and is made with the construction industry in mind.

Hybrid Systems

The hybrid system contains a two-part chemical anchor that cures quickly, allowing loading of the fastening point sooner than an epoxy anchor . This type sees service wherever that a threaded rod or rebar must install into concrete. In addition to structural steel connections to concrete, the hybrid system also sees use in racking, acoustic barriers, or fencing applications.

How Chemical Anchors Work

To maximize strength from the chemical resin bond, first, ensure a suitable hole is created.

Always make sure you know how deep you need to drill (based on the length of your anchor and the weight of your fitting) and that you won’t drill straight through. In this case, the resin simply runs through.

Resin injection anchor sleeves restrict resin flow and give a security fix to the substrate if your drilled holes are likely to have voids. This is common in bricks, but less so in concrete.

Chemical anchoring involves injecting a resin into the hole before inserting the stud. As a result, the chemical fills in all flaws and seals the hole, making it airtight and waterproof with 100 percent adherence.

Installation of Chemical Anchors

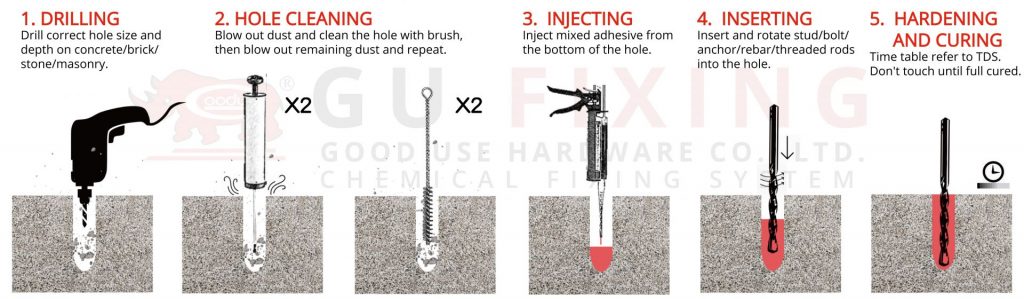

The following details the stages of installing a resin anchor:

- Drill the hole.

- To acquire the optimum hold against a debris-free surface, remove any loose material from the hole. Use a resin hole brush or pneumatic air to blast air into the hole.

- Inject the resin into the hole with an applicator pistol. Before injecting, ensure that it is correctly mixed. Then, double-check that the nozzle width and length are correct, and withdraw the nozzle slowly to avoid trapped air pockets. Use a resin nozzle extension tube on the end of a mixing nozzle to make deeper holes.

- Twist the stud a few times as it inserts it into the hole to dislodge any air bubbles. The resin also presses into any cavities in the spot. If the stud continues to push itself out, you may need to twist it a couple more times. All of the threads should evenly covered. If necessary, add extra resin.

- Leave the studs alone once they are set. Setting time depends on resin type as well as the temperature. Don’t load the studs until they’ve had time to cure completely.

Chemical Anchors vs. Mechanical Anchors

Both mechanical anchors and chemical anchors see wide use in civil engineering. Mechanical anchors and chemical anchors differ on a few key principles:

Tightening Stability

Mechanical anchors provide an inference fit. Given an acceptable substrate, they generally have steady performance and helps sustain the fastening force for an extended period. Chemical anchors’ performance primarily depends on the performance of chemical adhesives. As a result, selecting a suitable chemical adhesive is critical.

Seismic Performance of Chemical Anchors vs. Mechanical Anchors

Chemical anchor bolts’ screw material has low strength, tensile, and shear resistance, reducing seismic resistance. The level is low, essentially below grade 7. Mechanical anchor bolts’ screw material is high strength and provides better seismic resistance

Construction Cycle

Anchors that secure via chemical adhesives require a specific curing time, especially at low temperatures. In the winter environment in winter, the curing time is slightly longer, so the construction period is longer. Mechanical anchors are ready to use as soon as the concrete itself cures.

Installation Process

Chemical anchors, usually a mix of resin and hardener injected in a pre-drilled hole and then inserted with an anchor rod. Once the chemical cures, it hardens and bonds the anchor to the base material.

While installing mechanical anchors, the anchor is directly placed in the pre-drilled hole. Once required torque is given, it exerts expansion and frictional forces inside the concrete, through which it derives its strength and provides necessary resistance.

Loading Basis

If there is maximum shear force, then mechanical anchors are to be installed, and if there is tension force, then a chemical anchor is to be installed. Mechanical anchors secure themselves by screwing/wedging into the object at the tip. Mechanical anchors perform well against shear due to the interference fit which allows no movement.

Chemical anchors require a hole to be drilled, cleaned, filled with an adhesive, and then the anchor can be inserted. Chemical anchors and fillers perform great against tension due to the continual adhesion through the anchor length.

Applications of Chemical Anchors

Chemical resin anchors provide some advantages, including the ability to hold huge loads and the speed at which they may place. However, the installation of chemical resin anchors requires proper installation.

Chemical anchors see use in a broad variety of applications. Here are a few common ones:

Rebar Doweling

Base Plate Installation

Hollow Block Fastenings

Fastening Fixtures to Masonry