Anchor bolts attach structural objects to concrete structures. In the fabrication industry, anchor bolts commonly fix equipment, structural skids, and vessels to concrete. One end of the anchor bolt embeds into the concrete, while the exposed threaded end mates to the equipment. There are many types. Some of the common ones are L-shaped, double-end rods with plate, welded-headed stud, and swedge type. In this article, you’ll learn the details of each type of anchor bolt, the selection process, and the responsible parties involved in the installation.

Types of Anchor Bolts

Bent-bar Anchor Bolts

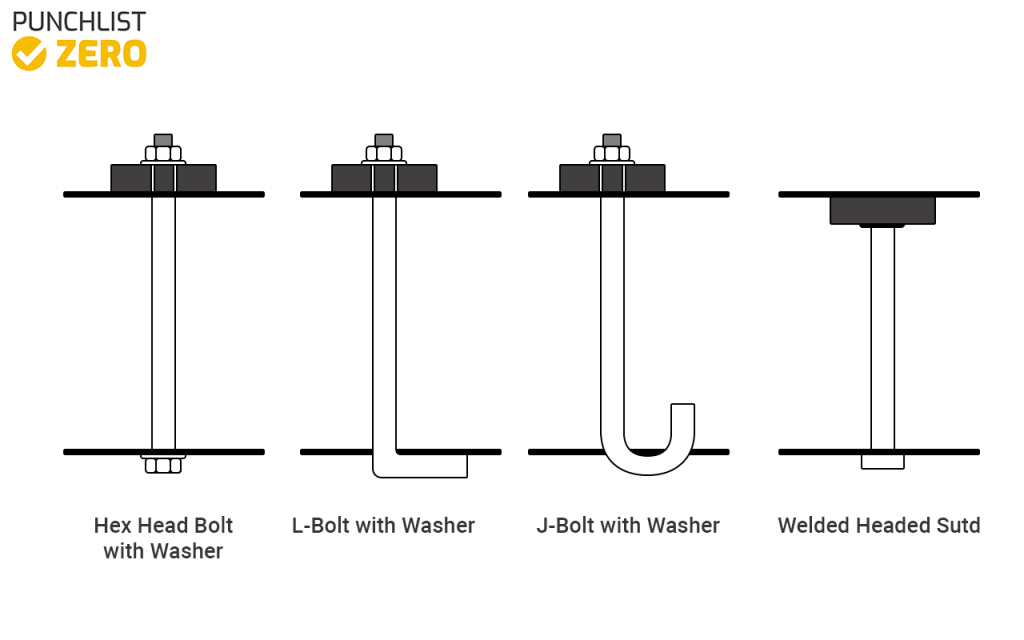

These steel rods have threads at one end with the other end bent into hooks. These hooks embed into concrete or masonry. They come in two types, either L or J shapes. Bent-bars see common use in signposts, poles, and other steel structures.

Double End Rods with Plate

These types of anchors take the form of double-ended rods with a plate washer at one end. The plate often welds to the anchor bolt itself, or welds to a nut embedded in concrete. Plate bolts see common use in constructing building columns road signs, light poles, and other structures.

Headed Anchor Bolts

These bolts have a forged head on one end, typically designed as a hex, or a square head. The head embeds into the concrete. If a metal plate welds to each side of the bolt then they categorize as plate anchors. These plate anchors still classify as headed anchor bolts. These types of fasteners provide a nice look at the surface without the protruding nut and bolt. They apply to avariety of construction applications such as bridge railing, and light poles, etc.

Swedge Bolts

These fasteners consist of round bar steel, threaded on one end and “swedged” on the other end. “Swedge” means that they have many indentions that allow them to get a better grip in the concrete. They see common use in girders and piers construction.

Selecting the Right Anchor Bolt

When you connect a piece of equipment to concrete, it should hold for a lifetime. That is why it is essential to select the right anchor bolts for your application. There are many issues to consider when selecting an anchor bolt to fasten an object to the concrete structure. First, it is important to determine the size of the hole for the anchor bolt and its length. Some anchor bolts are designed for concrete, while others for cement or masonry work. The selection of the right fastener depends on the base material to which the object anchors.

Generally, the preferred method of securing involves directly casting them into the concrete prior to curing. However, civil contractors don’t always know the required fastening location due to late arriving or not yet determined equipment. In such cases, drill-in-place anchors secure equipment to the slab. This occurs via a mechanical interference fit or via the use of a chemical anchoring system.

Various Scenarios

When choosing the right fastener for the job, you will want one strong enough to hold the strain of the load but without compromising on the stability of the complete structure.

You must be aware of the total load that the anchor may hold. The anchor bolt is the weakest point in the concrete structure and therefore its strength and its diameter depend on the supported weight. For maximum safety, specify the strongest, largest, and deepest bolts.

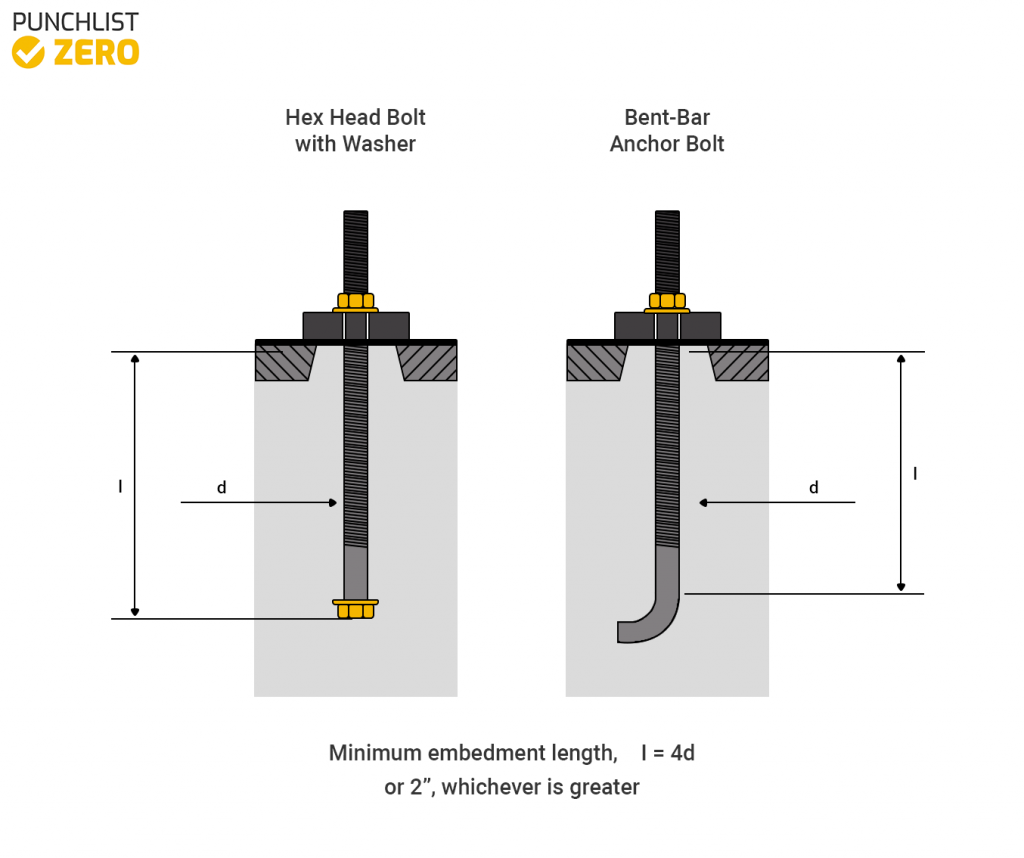

In general, as diameter increases, load and carrying power also increases. Also, the best holding value occurs in deeply embedded anchors within very hard concrete. A 1/2″ anchor set with a minimum embedment of 2″ produces a stronger hold than a 1/ 4″ anchor with a minimum embedment of 1″.

Another thing to consider is where the load that the anchor bolts will be holding will be fastened to the concrete. For loads that attach overhead to a wall, specify stronger bolts. For loads fastened on the edge, resting on the ground, smaller diameter bolts can be sufficient.

Length of the Fastener

The National Concrete Masonary Association recommends a rule of thumb for the length of a fastener embedded into concrete. The effective embedment length shall be 4d or 2″, whichever is greater.

Other Considerations

When deciding on the anchor bolt for a job, the structure’s environmental conditions require consideration.

Anchor bolts design includes the bolt coming through the fixture. The length of the bolt extending through it depends on how many times it needs to be tightened and how the nut was located in the concrete before the bolt was put into place. For a finished look, use a uniform-headed anchor bolt. Flat or round-headed sleeve anchors have smooth heads that protrude from the fixture and look uniform. You could also use female anchors such as single and double expansion anchors, machine screw anchors, or drop-in anchors to achieve the same look.

When considering the weight of the load that anchors must hold, it’s important to understand that the bolt is the weakest link in the concrete structural system. With this in mind, determine the required diameter of the anchor bolt based depending on the weight that’s held. The strongest and deepest set anchor bolts with the largest diameters fit heavy loads fastened to the concrete.

Vibration Loading

Equipment bonded to concrete experiences the same vibrations that the equpment does during operation. An equipment’s vibration characteristic require independent evaluation prior to installation. Vibrating structures include pumps, motors, fans, moving belts, or even signs blowing in the wind.

An anchor bolt transfers the shear and tension applied on it through friction but if friction reduces from continuous vibration, its holding power will be diminished. In such cases, a stronger, bigger, and deeper anchor bolt should be used.

Shock Loading

Any equipment fastened to the concrete where there is a shock load, has to withstand load changes over a period of time. A common example of a shock load would be a bumper on a dock. Since mechanical anchors can provide holding values based on the friction of the bolt against the walls of the hole, if the friction is broken, the holding value will diminish. Shock loads may slowly loosen the anchor bolts over time.

Responsibilities

There are many different characteristics when choosing the right anchor bolt for your application. The type and strength of the concrete, the fixture size and location, the type of environment, and the desired look of the finished product warrant consideration. The correct sizing and spacing of anchors are critical in any structural application. For this reason, it’s extremely important to design the structure in consultation with a specialist structural engineer.

It’s essential to determine the overall responsibility for anchor bolt design. Frequently, multiple fabricators deliver equipment to a singular site. Responsibility for anchor bolt design and delivery generally should lie with the company charged with overall engineering responsibility. To complete this task effectively, equipment providers only must deliver equipment details such as weight, height, and center of gravity to the supplier charged with packaging.