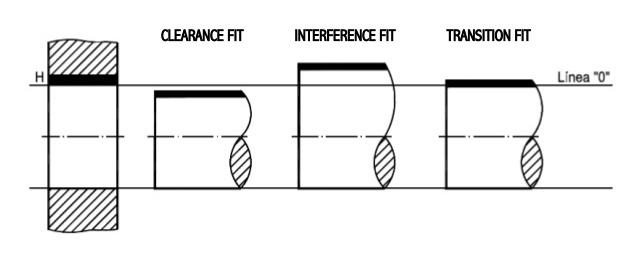

Engineered products frequently must slip or press against each other to deliver their functions. The way products interact is designed as an engineering fit. There are three types of engineering fit: clearance, interference, and transition.

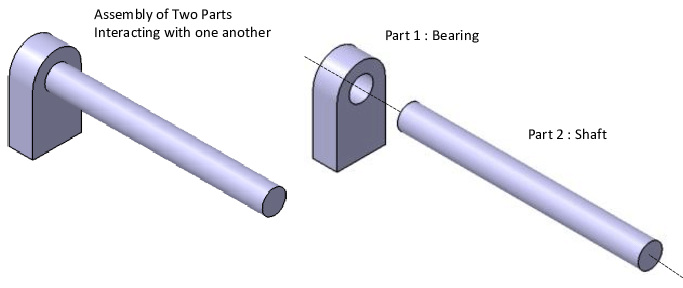

Engineering fits often refer to shaft and hole pairings, but are not limited to round components. While engineering fits apply to a wide range of mating parts, their primary function is to regulate the sizes of mating shafts and holes.

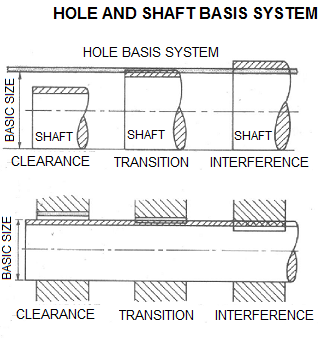

Fits are either shaft or hole-based. The hole’s size keeps constant for a hole-basis system while the shaft alters to determine the fit. The reverse is for the shaft-basis systems where the shaft size is consistent, and the hole size changes to determine the fit.

In this article, you will learn the types of engineering fit and common applications.

Types of Fit in Engineering

Fits are classified into three categories by ISO and ANSI: clearance, transition, and interference. Each class includes several alternatives for selecting the best one for a particular application.

Clearance Fits

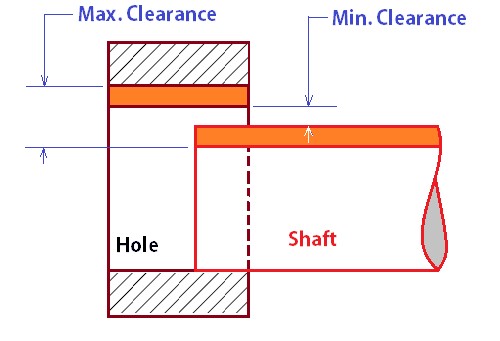

The shaft is always smaller than the hole in a clearance fit. This allows for simple construction while also allowing for sliding and rotary mobility.

A maximum clearance occurs when the shaft diameter is the smallest and the hole diameter is the largest. In the same manner, minium clearance occurs when the shaft diameter is at its maximum, and the hole diameter is at its smallest.

There are six different types of clearance fits. From the loosest to the tightest, they are:

- Loose running

- Free running

- Close running

- Sliding

- Close clearance

- Locational clearance

Loose Running Fit

With the most clearance, fit-up is not a concern. A loose running fit is suitable for applications where precision isn’t critical and contamination is a possibility.

Free Running Fit

When there are no exceptional criteria for the accuracy of matching parts, this is the best option. A free-running fit allows movement in settings with extreme temperature swings, fast running speeds, and high bearing pressures.

Close Running Fit

For applications requiring small clearances and moderate accuracy, close-running fittings are a good choice. This type of fit withstands medium speeds and pressures well.

Sliding Fit

The sliding fit allows for a bit of clearance for high precision while keeping construction simple. Parts may quickly turn and slide.

Locational Clearance Fit

For high precision requirements, location clearance fits may be the best option. The assembly does not require any force, and the mating pieces can freely turn and glide thanks to the lubrication, making installation by hand easier. For immovable parts, it ensures a tight fit.

Transition Fits

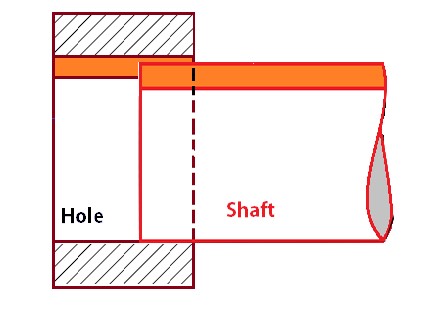

This type of engineering fit results in a shaft that may be larger than the hole or a shaft that is smaller than the hole. Thus, the term transition fit applies.

When you specify a transition fit, both results are achievable even within a single batch.

Transition fits are available in two styles: similar fit and fixed fit.

Similar Fit

A similar leaves a small gap or causes a minor obstruction. A rubber mallet can be used to put the pieces together.

Fixed Fit

The fixed fit leaves a smaller gap than the similar fitgap and may also cause a minor obstruction. Light force can put the pieces together.

Interference Fits

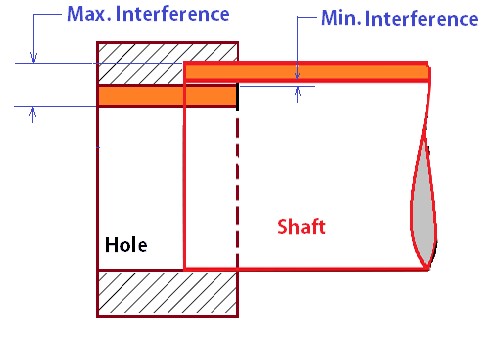

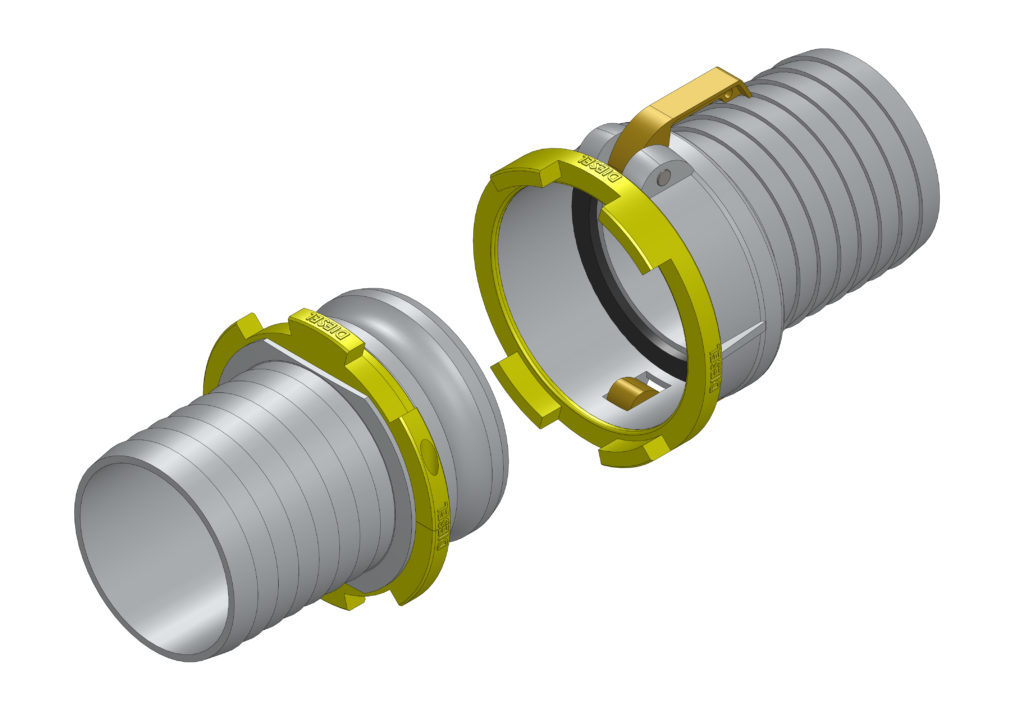

Press fittings and friction fits are other names for interference fits. The rationale behind these types of fittings is that the shaft is larger than the hole size.

The assembly stage necessitates the use of force, lubricant, hole heating, and shaft freezing. These aid in increasing/decreasing the hole and shaft sizes, respectively, to make the operation easier.

This type of engineering fit is adequate for components under significant torque and speed as the interference helps to secure the relative location of the shaft and hub even during rotation.

Press Fit

Minimal interference. Assembly can be performed with cold pressing.

Driving Fit

Cold pressing necessitates greater assembly forces. The use of hot pressing is another option. When compared to a press-fit, the interference fit is more noticeable.

Forced Fit

This type of engineering fit sees a lot of interference. The mating components press together, often with the hole heated and freezing of the shaft. Disassembly often results in broken parts.

Applying Engineering Fit Type to Real World Applications

The required application determines whether a clearance, transition, or interference fit shall be used.

Clearance Fit

It is used between those mating parts where no precision is required and provides a minimum allowance.

Common applications by the type of engineering fit are as follows:

- Loose Running Fit – Fittings that have been subjected to dust, corrosion, heat, and mechanical deformations. Pivots, locks, and other hardware

- Free Running Fit – Applications in which a thin film of oil lubrication is required. Shaft and simple bearing, for example, fit with little rotational movement.

- Close Running Fit – Machine tools, sliding rods, spindles for machine tools, and so on.

- Sliding Fit – Shafts, sliding gears, slide valves, vehicle components, clutch discs, machine tool parts, and so on.

- Locational Clearance Fit – Roller guides, guiding of shafts, etc.

Transition Fit

There are two types of transition fits push-fit and mild keying fits. The similar fit sees common use in hubs, gears, pulleys, and bearings. The tighter fixed fit is common for armatures on shafts.

Interference Fit

Interference fits are widely used with fasteners to increase fatigue life by inducing compressive stress around holes. Press-fit applies to hubs, bearings, and bushings.

The tighter driving fit applies to the permanent mounting of gears and shafts.

The ultra-tight forced fit applies to gears and shafts that undergo a large amount of torque or speed.