The article answers many common questions about ASME. Questions include: What exactly is ASME? What is ASME Certification, and why is it important? What is ASME code, and what does it mean? ASME B31.3, ASME B31.1, B16.5, B16.34, and Y14.5 code reviews are also discussed in this article.

What is ASME?

The American Society of Mechanical Engineers (ASME) is an American professional association. In reaction to multiple steam boiler failures, Alexander Lyman Holley, Henry Rossiter Worthington, John Edison Sweet, and Matthias N. Forney created ASME in 1880. ASME is best known for developing mechanical device codes and standards. But it also runs one of its largest technical publishing businesses. It holds numerous technical conferences and hundreds of professional development courses each year and sponsors multiple outreach and educational programs.

It is a nonprofit organization that provides training and education. ASME, founded in North America as a mechanical engineering society, has evolved into a multidisciplinary global organization. Through continuing education, training, codes and standards, and other forms of outreach promote the art, science, and practice of multidisciplinary engineering and allied sciences worldwide.

In fact, it has over 130,000 members in almost 160 countries worldwide, and about 30% of them are students. Project managers, career engineers, researchers, corporate executives, and academic leaders are also among the other members. ASME provides high-quality programs in various sectors to a broad range of the technical community, and it develops performance test codes (PTCs) to provide standard methods and guidelines for the preparation, planning, reporting, and execution of these tests findings.

What is an ASME Standard?

The ASME standards are technical guidelines for designers, manufacturers, and end-users to use a product. Some of these standards are only a few paragraphs long, while others may be many pages long.

Because they are globally recognized, the ASME standards are helpful. Their use allows manufacturers and users to communicate more quickly and effectively. When a measure accepts by one or more governmental organizations and made enforceable by legislation or incorporated into a business contract, it becomes a Code.

What is ASME Certification?

ASME certification provides a straightforward way to tell customers, supply chain, industry, and regulators that your company is committed to public safety and quality. To gain ASME certification, applicants evaluate all information relating to their program, including the applicable forms, checklists, and associated fees. It ensures that applicants understand the accreditation/certification program entirely before applying. Before, make the following preparations:

- Look up pertinent information regarding the chosen certification program on the ASME website.

- Determine the extent of work that will be ASME certified.

- Obtain required standards.

- Agree with an Authorized Inspection Agency (AIA) if required by the applicable standard.

- Prepare the quality manual, a written description of the quality program.

- Indoctrinate and train personnel to implement the quality program.

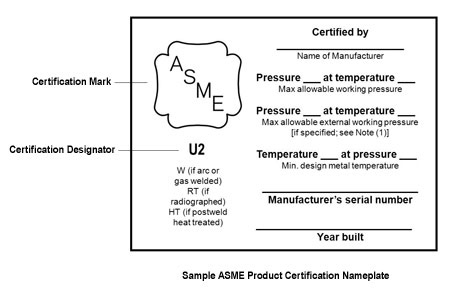

Also, a corporation must go through a 6-month procedure to become ASME certified, ensuring that all operations are consistent with the code and done to the highest standards. The result is the ASME Certification Mark, which signifies that the product in question is manufactured from high-quality materials and is very safe to use.

What is ASME code?

The ASME code, often known as the ASME Boiler and Pressure Vessel Code or BPVC, governs the design, development, and construction of boilers and pressure vessels used in a range of sectors.

In addition, ASME Code is broken down into parts for different sorts of components (steam boilers, heating boilers, pressure vessels), fabrication and testing methods (welding, NDE), and materials, among other things.

Code Cases (special permits for designs or materials not covered by the code), Interpretations (ASME issued explanations), reference standards (e.g., ASME B16.5 Flanges, ASME B16.9 Fittings), and other standards, such as those for pipes, are also available.

What is the significance of this? It’s critical to choose a heating system that complies with ASME’s BPVC for a variety of reasons, including:

Safety

Following two fatal boiler explosions at plants in Massachusetts in the early 1900s, ASME established the Boiler & Pressure Vessel Code. Since then, the BPVC has issued guidelines to make steam boilers and other mechanical engineering equipment safer, hence reducing the number of accidents.

Quality

On the other hand, ASME-stamped industrial heaters and boiler systems have thoroughly inspected and passed the Boiler & Pressure Vessel Code’s quality and safety standards. When you buy a system that follows the BPVC regulation, you ensure that you’re getting a high-quality piece of machinery for your business or facility.

ASME B31.3 Process Piping

ASME B31.3 specifies plumbing requirements for petroleum refineries, chemical, pharmaceutical, textile, paper, semiconductor, cryogenic plants, and allied processing plants and terminals. It also encompasses piping materials and components and design, fabrication, assembly, erection, inspection, and testing.

This code applies to any fluid piping, including:

- raw, intermediate, and finished chemicals;

- petroleum products;

- gas, steam, air, and water;

- fluidized solids;

- refrigerants; and

- cryogenic fluids.

Also included is the piping that interconnects pieces or stages within a packaged equipment assembly.

ASME B31.1 Power Piping

ASME B31.1 sets standards for power piping fabrication and installation. Power piping standards apply to electric generation stations, industrial and institutional plants, central and district heating plants, and district heating systems. Furthermore, the Power Pipe Code regulates the design, material, fabrication, construction, testing, and inspection of power and auxiliary service pipe systems. The application of ASME B31.1 varies by project and will be specified by the asset owner or an asset owner’s representative.

In addition to those covered by other sections of ASME B31, ASME B31.1 excludes the following pipe systems:

- Economizers, heaters, pressure vessels, and other components covered by the ASME Boiler and Pressure Vessel Code

- Building heating and distribution steam piping with a pressure rating of 15 psig or less, or hot-water heating system piping with 30 psig or less.

- Roof and floor drains, plumbing, sewers, sprinklers, and other fire safety systems require piping.

- Downstream of the system distribution header’s first stop valve is piping for hydraulic or pneumatic tools and their components.

- Piping for federally controlled marine or other installations

- Different portions of ASME B31 and ASME Section III cover piping.

- ANSI Z 223.1, National Fuel Gas Code, applies to fuel gas piping.

- Pulverized fuel piping within the scope of NFPA

B16.5 Pipe Flanges and Flanged Fitting

The standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and identifying apertures for pipe flanges and flanged fittings. It includes the following:

- Flanges in sizes NPS 1/2 through NPS 24 with rating class designations 150, 300, 400, 600, 900, and 1500, and flanges in sizes NPS 1/2 through NPS 12 with rating class designation 2500, with requirements stated in both metric and U.S.

- Flanged fittings with rating classes 150 and 300 in NPS 1/2 to NPS 24, with metric and U.S. specifications.

- Flanged fittings with rating class designations 400, 600, 900, and 1500 in sizes NPS 1/2 through NPS 24 and 2500 in sizes NPS 1/2 through NPS 12 recognized in Non-Mandatory Appendix E in which the only U.S. Standard units are available.

The standard also applies to flanges and flanged fittings made of cast or forged materials, blind flanges, and reducing flanges made of form, developed, or plate materials. B16.5 should be used in conjunction with other ASME B16 Series of Standards and different ASME standards. Examples include the Boiler and Pressure Vessel Code and the B31 Piping Codes.

B16.34 Valves Flanged, Threaded, and Welding End

This standard applies to forged, fabricated, flanged, and threaded valves. It covers pressure-temperature ratings, dimensions, tolerances, materials, nondestructive inspection requirements, testing, and labeling. Flanged-end valves include welding end and wafer or flangeless valves made of steel, nickel-base alloys, and other wafer or flangeless valves that are bolted or through-bolted and mounted between flanges or against a flange. Alternative guidelines offer NPS 212 and smaller valves.

Y14.5 Dimensioning and Tolerancing

The Y14.5 standard establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting geometric dimensioning and tolerancing (GD&T). It establishes these requirements for use on engineering drawings, digital models, and associated documents.

Also, GD&T provides a critical tool for communicating design intent to ensure that parts from technical drawings have the intended shape, fit, function, and interchangeability. GD&T standardization provides uniformity in drawing requirements and interpretation, improving quality, saving costs, and shortening delivery times.