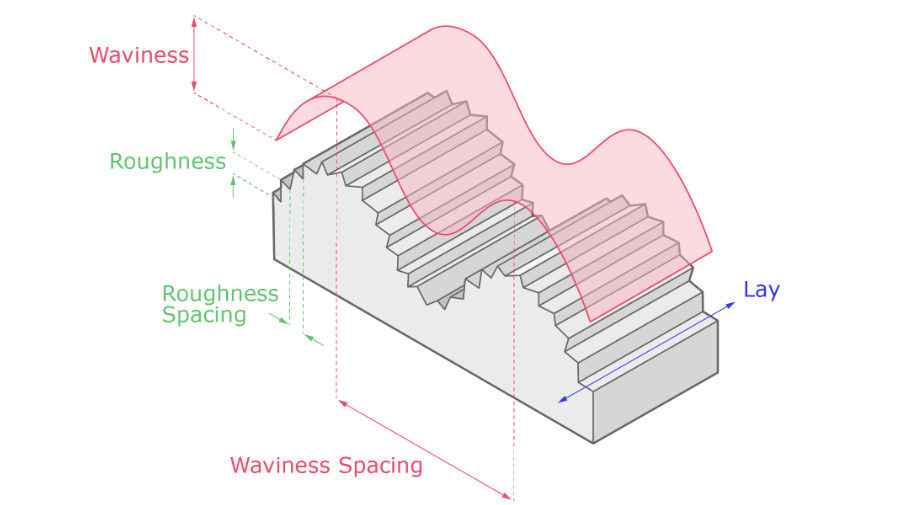

Surface finish symbols characterize the overall texture of a surface. Often, this characterization is in terms of only the surface roughness. But an in-depth description covers other parameters such as the lay and waviness of the surface. In this article, we discuss the use of surface finish symbols and relevant standards, discuss the Ra and Rz parameters, as well as compare them.

Why Use Surface Finish Symbols

Surface finish symbols are key features in engineering drawings when communicating geometrical dimensions of a product. These symbols indicate the quality of a surface by describing its appearance or feel. There are several reasons why these symbols are important to engineers, product designers, and other professionals involved in manufacturing.

- Friction and Wear: The texture of a material’s surface determines the amount of friction it is subject to. For example, a smooth surface experiences less friction and wear, whereas a surface with high roughness experiences more friction. Either could be desirable when manufacturing a part, depending on its functionality.

- Adhesion: The surface roughness of a part also influences its ability to adhere to paint, coatings, and other materials. Surfaces for painting are best manufactured with a bit of roughness to ensure adhesion. Smoother surfacess have less surface area, and subsequently less adhension.

- Aesthetics: Having a visual appeal is important for certain products and surface finish symbols help communicate this.

Other ways that a surface finish can influence a product include:

- It eliminates surface defects.

- It improves conductivity and adds surface electrical conductions.

- Surface finish impacts the corrosion and chemical resistance of a material.

Different parts of the world utilize unique surface finish symbols and standards. Out of these, the most recognized are the ASME Y14.36 in the US, while the rest of the world uses ISO 1302.

ISO Surface Finish Symbols

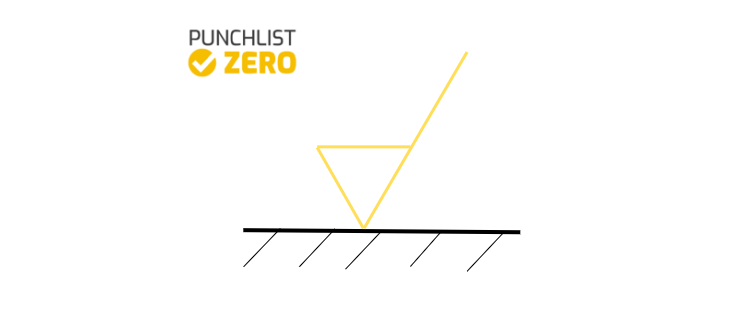

- Basic Symbol: This symbol indicates that the manufacture of a surface could be by any method.

- Material Removal by Machining: Adding a horizontal bar to the basic symbol indicates the requirement of material removal to produce a surface.

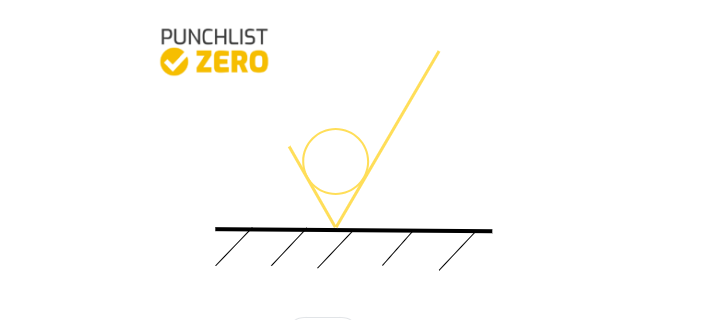

- Material Removal Prohibited: The introduction of a circle to the basic symbol indicates the prohibition of material removal. Rather, processes such as casting, cold or hot finishing, and powder metallurgy should be used in forming the surface.

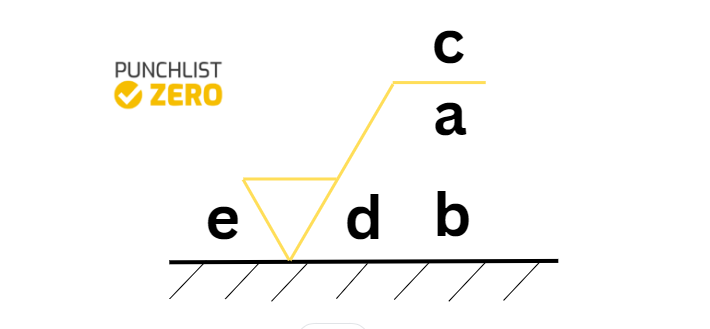

In addition, there is a symbol ideal for surface finish callouts with room for several parameters as the figure below shows.

- Manufacturing method – c.

- First surface texture requirement – a.

- Second surface texture requirement – b.

- Surface lay as well as orientation – d.

- Machining allowance – e.

ANSI/ASME Surface Finish Symbols

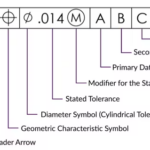

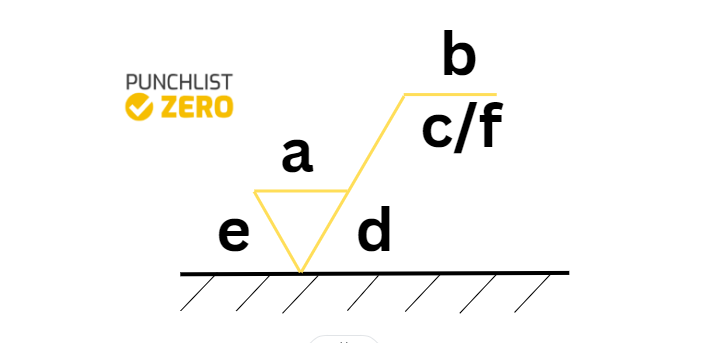

Similar to the ISO standard, the ASME Y14.36 has a surface texture symbol with several parameters.

- The average roughness value (Ra) – a.

- The production method, coating, or additional information – b.

- Roughness sampling length in millimeters or inches – c.

- The direction of the surface lay. – d.

- Minimum material removal requirements in millimeters – e.

- The symbol as well as the value of an alternate surface finish parameter – f.

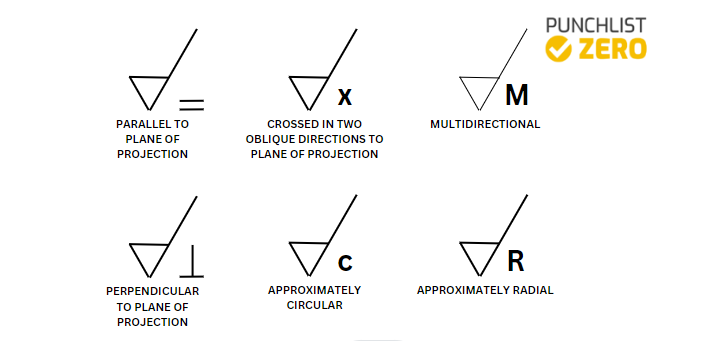

ASME surface finish symbols also include those indicating the direction of lay as the figure below shows.

Ra

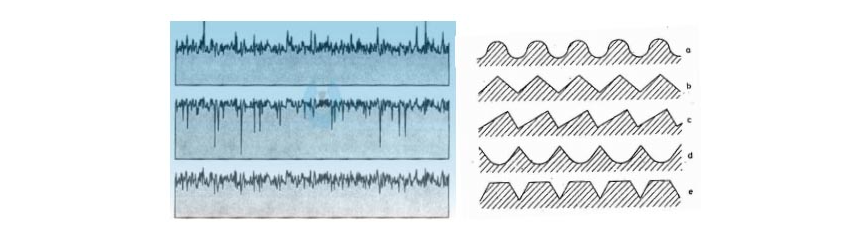

Ra is a roughness parameter that indicates the average variation of the roughness profile from the mean line. It is the most common surface finish parameter and is also referred to as arithmetic average or common line average. Because of the averaging, the Ra value is usually lower than the actual height of the roughness variations. So, utilizing it alone does not completely characterize the roughness of a surface as the figure below highlights.

Clearly, the profiles of the five surfaces (a – e) in the figure above are different, however, they all have the same Ra value. Showing the insufficiency of using only Ra to define a surface roughness. Despite this shortcoming, Ra remains predominant because of its ease of measurement using either analog or digital devices.

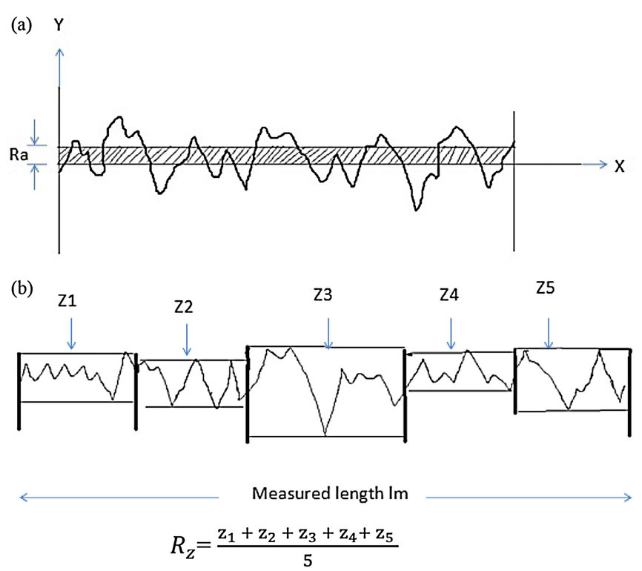

Rz

Another common surface finish parameter is Rz. It measures the average values of the five largest differences between peaks and valleys within five consecutive sampling lengths of a surface. This makes it more sensitive to extremes in comparison to Ra. As such, it is the preferable parameter in Europe, especially Germany.

Ra vs Rz Surface Finish Units

| Characteristics | Difference Between Ra and Rz |

| Definition | Ra indicates the average surface roughness of a profile. Whereas Rz quantifies the average maximum height of a profile. |

| Sensitivity to Extremes | Ra is relatively insensitive to a few extremes, while Rz is sensitive to extremes that it measures. |

| Conversion | Because Ra and Rz are measuring different quantities, there is no relationship between them. However, statistics show that if Rz is known, then Ra is about seven times less than it. On the other hand, if Ra is the known quantity, Rz is about 20 times more. |

| Measuring | Ra is easier to measure than Rz. |