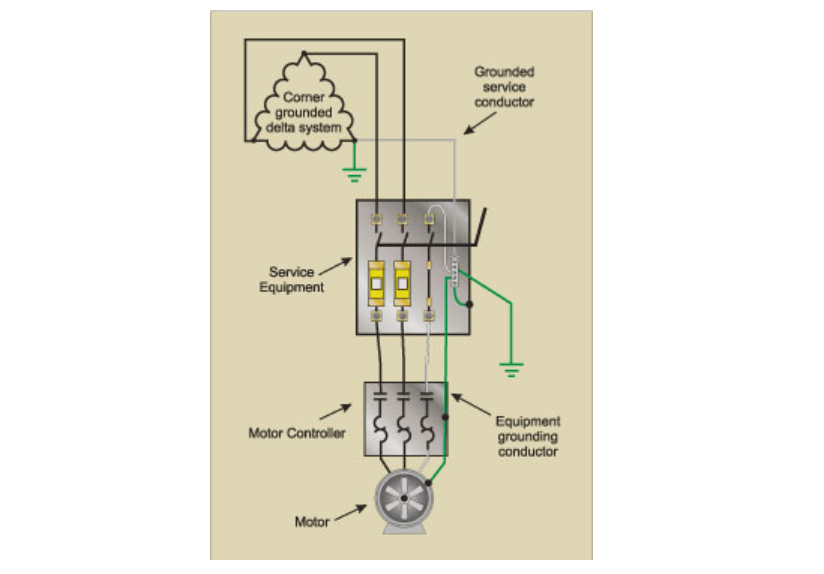

A corner grounded delta system is a three-phase delta service with one phase having the ground connection. This configuration goes by several names including grounded leg/phase service, end-grounded delta system, and grounded B phase system. In this article, we review the application of corner grounded delta, review the dangers of this system, and compare it vs a high leg.

Applications of Corner Grounded Delta

The corner grounded delta (CGD) is one of the earliest forms of grounded systems in electrical installations. Because of the disadvantages of not grounding systems, electrical designers had to integrate a ground reference to existing configurations. Doing this is technically challenging and expensive, however, the corner-grounded system offers a low-cost method of grounding a delta configuration. Generally, the grounding could be on any of the three phases from the transformer secondary, but the choice is usually the second or B phase for easy tracking. A CGD system offers the following benefits:

- Reduces the generation of transient overvoltage that occurs in systems without grounding.

- Establishes a ground reference for each current-carrying conductor.

- Offers a low-cost option to introduce a neutral line that will be grounded.

Despite these advantages, the use of corner grounded delta is limited to old installations. This is because recent grounding methods are more suitable and reliable. However, it is common to still encounter CGD systems today for the following reasons:

- Almost all low-voltage systems in the past used transformers with delta-connected secondaries for power distribution. So, grounding the corner of one of the delta phases was the simplest way of making these systems safe.

- It helps avoid the installation of equipment ground fault protection on solidly wye electrical services, which is an NEC requirement.

- Also, CGD systems promote the use of less expensive equipment, as two-pole switches and the neutral could serve in three-pole applications.

Examples of CGD Devices

In modern applications of corner-grounded delta system, it is necessary to have equipment ground fault protection. This is due to the potential high fault currents on the first ground fault. As a result, equipment used on a CGD system requires testing and approval from industry regulators. Examples of approved devices that are UL-listed include:

- Molded case circuit breakers.

- Safety switches.

- QMB and QMJ switches.

- BP fusible switches.

- Panelboards such as QMB panelboards, I-Line circuit breaker panelboards, as well as NQOD and NF circuit breaker panelboards.

- QED switchboards.

Dangers and Disadvantages

There are several factors that make corner-grounded delta systems less popular in modern applications. Some of the dangers of using this system are:

- The potential to the ground is significantly higher than in a neutral-grounded system. For example, in a 480V system, the potential is 480V to ground rather than 277V. This can lead to significant voltage delivery for any device on the grounded leg, making them prone to damage.

- Also, this system experiences more severe fault switching for the clearing device, which could greatly reduce its ratings.

Other disadvantages of this system include:

- Corner-grounded delta systems do not work with lower-cost slash-rated circuit breakers such as 480/277V and 240/120V.

- Any equipment in this configuration requires significant testing and approval before use. Also, having equipment ground fault protection is necessary for safeguarding equipment. It is recommended to follow UL listings if connecting equipment on this configuration.

- Because the grounding is on one of the phases, ground fault sensing for that phase is undefined. As a result, this configuration cannot be used in locations where ground faults are required such as healthcare facilities.

- To avoid confusion, the corner grounded phase needs some form of identification throughout the network. Else, it could be mistaken for a faulty line as it would have a zero potential to ground, while the other two lines will have higher voltage to ground.

Corner Grounded Delta vs High Leg Delta

Another common configuration is the high leg delta. This configuration also goes by the names wild-leg, stinger leg, and dog leg delta. They are common in three-phase delta transformers that intend to also supply single-phase electricity. As a result, a neutral line is introduced by center-tapping one of the phases. The voltage between this neutral line and the line opposite it is higher than for the other two lines adjacent to the neutral. Thus, the name “high leg” delta.

Differences between the corner grounded and the high leg configurations are as follows:

| Corner Grounded Delta | High Leg Delta |

| The ground connection is at the corner of one of the phases. | While the ground connection is at the center point of one of the phases. |

| Can provide a variety of voltages at a lesser cost. | It is a three-wire system and supplies only three-phase power. |

| Supplies only a single voltage. | Usually serves in residential power supply where the single phase delivers 120V for lighting and low-load devices. While the three-phase sends 240V to high-load equipment such as washing machines and HVAC. So, it is effective as a split phase supply. |

| Usually serves in residential power supply where the single phase delivers 120V for lighting and low-load devices. While the three-phase sends 240V to high-load equipment such as washing machines and HVAC. So, it is effective as a split-phase supply. | On the other hand, one of the legs has a higher voltage to the ground than the other two legs. |

| Two legs have a higher voltage to the ground, while the phase with the grounding has zero potential to the ground. | Even without markings, it is easy to identify lines on this system. Because the high leg and every third circuit afterward will be either a three-pole breaker or a blank. |

| Requires some means of identification for the corner grounded line throughout the system. | Can serve in industrial applications such as 240V and 480V power supplies. |