The biocheck valve solves an expensive problem that exists with lagoons and biogas. Colin Burton of Punchlist Zero sat down with Brian Crook to talk about this valve and potential future applications.

PL0: Tell me about this Bio-Check valve. Where did you get the idea?

Brian: The Bio-Check Valve started with an old friend of mine in the valve industry. He’s been supplying piping, flanges, and all sorts of stuff for the biogas industry. In the United States, the biogas industry is in its infancy. As opposed to Europe, they’ve been doing it for roughly 20 years, they have a good system for it and a good supply chain.

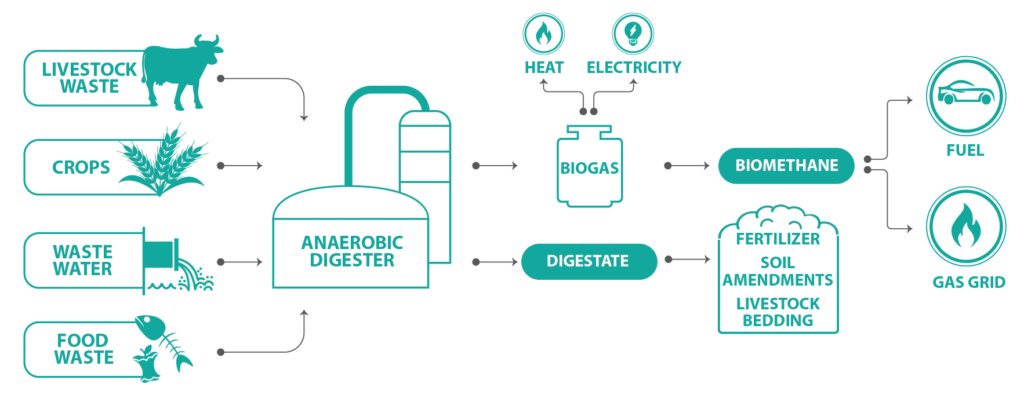

In the United States, the predominant way to store biogas is via a lagoon. The lagoon is a giant pond, maybe the size of four to eight football fields. It’s lined with a rubber membrane that rests on top. The biogas generation process places manure, meat scraps, and biomass material into a pile and allows it to decompose.

The decomposition produces methane gas, which flows into ponds. A significant issue occurs because the ponds lose pressure and rests on the water. The pressure then drops and the digesters membrane hits the water surface. What results is the system sucks up water, resulting in shut down of the gas processing equipment.

My friend Kenny Despot came to me and told me about this problem that biogas companies were having. The more he talked, the more I realized we could solve this problem. We took the concept to a biogas trade show in May 2023. People were blown away and said, Hey, this solves a problem that we have.”

PL0: How is this valve different from what’s currently in the market?

Brian: What’s currently on the market, you have ball checks and swing checks. You have different things like vacuum breakers, all of those things serve a specific purpose. So if you look at most of your check valves, they control flow in one direction. What we weren’t trying to do with this was control flow.

We were trying to keep the liquids from leaving the digester. We came up with a way to actually shut off the orifice when the water level rises. We designed a mechanical vacuum breaker to break the vacuum when the water level drops. It is a repeatable device, it’s self-operating, and it doesn’t require any input from any control system. It can serve digesters with multiple hatches and entry points.

PL0: How has your experience in the industry helped with the creation of this new valve?

Brian: I believe that my career has been made because I’ve always focused on solving people’s problems. The Bio-Check solves a problem and that’s a reflection of who I am and what my career has been about.

And, it’s kind of like a crowning moment to say, Hey, I did something that maybe changed the industry in a positive way. So I think that that’s what drove the creation of it, as wanting to solve someone’s problem and then having the knowledge to do it and then executing it. So it hasn’t been easy. It’s been a lot of work, but it’s been worth it. Rewarding.

PL0: Who needs to know about this valve?

Brian: Anybody that is in the biogas digester business. We’re dealing right now with the largest biogas digester manufacturer in the United States. They’re kind of what got this process started. There are a few other ones that are in the market as well. It is a growing business. This is a new problem because it’s a new industry and that’s why our product is unique because it’s a new problem, a new industry, and it’s a new product that solves that problem that they’ve discovered as they’ve started building these. Currently, there are probably about 200 dairy digesters in service in the United States.

It makes sense to take cow manure that normally goes in a pile and instead put it in a pond and capture that gas. It’s responsible, caring for the environment and it’s just logical to use stuff that just sits there.

For those working with dairy farmers, my advice to them is to look into a digester because it’s affordable and it produces additional revenue for them. I think that the Bio-Check is about to become a standard on these digester systems because it solves a very expensive problem that exists with lagoons.

So we’re looking forward to that and looking forward to providing solutions to it. We’ve had people ask us if there are other products that we’d be willing to look at designing and whatnot and the answer to that is yes. Lee Bares and I are both partners of SVC and are flexible in solving our customer’s problems.

PL0: Where do you see the Bio-Check valve taking you in the future?

Brian: We’re working on a lot of other products. The culture of our company is built around hard work, being responsive, producing a great product, an also solving problems, which is reflected in all of our employees. Perhaps the Bio-Check valve is the beginning of something new for the industry or the beginning of maybe a brand of products that are used for the biogas digesters.

I’m open to looking at other applications and developing other products that can really change people’s lives. We can produce a product and employ a good staff of people who provide for their families. That’s really my goal at the end of the day.

Email Brian Crook for further information on the Bio-Check valve at brian@sovalvecontrol.com.