Travis Ziebro of Punchlist Zero and Benjamin Treuhaft of Helpful Engineering had a free-ranging conversation about the future of engineering and open source product development. The highlights are captured below.

PL0: Tell me about Helpful Engineering. How did it get its start and what is the team looking to accomplish?

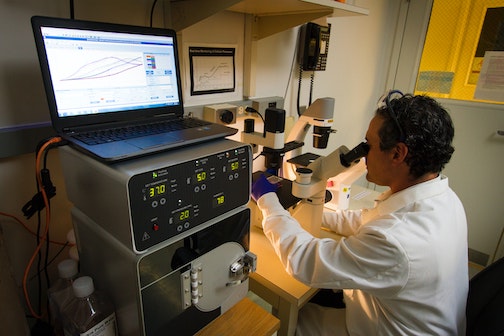

Towards the beginning of 2020, a variety of data sensitive people, engineers, bio researchers, etc., began actively anticipating COVID would become… a problem. It also became clear that governmental responses were flawed as were market allocation mechanisms. Incredibly, there seems to have been no systematic way for most of the Western world to respond to this type of infectious disease outbreak.

As such, at the beginning of March, when it became very clear that this pandemic was going to cause global mayhem, a group of economists, biomedical researchers and engineers based out of America and the UK, respectively started a Slack workspace to try and figure out what they could do to mitigate the impact of this pandemic. Some people had connections to reddit and other communities, and started reaching out to friends. And all of a sudden – boom. Attention really skyrocketed.

It took only about two to three weeks for the community to reach 15,000 volunteers, and now it’s over 18,000. The early people in the Helpful Engineering community deeply cared about getting stuff done. There was a single-minded focus on quality of execution as well as the passion to do it. It was not uncommon from April to June to see these teams work nearly 20 hour days seven days a week because people felt they needed to do this. If not them, who?

Many of those teams and key organizational people are still around today, and are guiding and shaping Helpful with the benefit of lessons learned.

PL0: How did you and your co-CEO Khadija get involved?

Both Khadija and I were in the community by early/mid April. I was originally running a hardware team but there was clear urgency that management skills were lacking. My background is as an entrepreneur in advertising technology and digital services and support, but I’ve also done some Industrial Design and Product Development, and I grew up in a medical household with an Orthopedist for a father who also designed his own surgical tools and a mother who ran Regulatory at several of the worlds largest pharma companies, so I have a pretty good sense of what product development and safety in this space looks like.. Khadija is an Electrical Engineer who also has an MBA and years of global management consulting experience.

I was originally asked to assume the role of CEO at the end of May/beginning of June, and after working with Khadija to develop our project pipeline, I quickly asked her to come to work directly with me as Co-CEO because we have complementary skills. We conceptualize and problem-solve together, and I mostly voice that work and handle outreach, messaging, and manage the process of aligning goals and teams. Khadija is one of the most talented, effective executives I’ve ever had the good fortune to work with as she can diagnose a problem and map a clear strategy and solution on the spot. Along with the rest of the executive team at Helpful, and with the benefit of our Community’s input, we’ve been able to quickly define and organize Helpful and get oriented in ways that best serve our common mission.

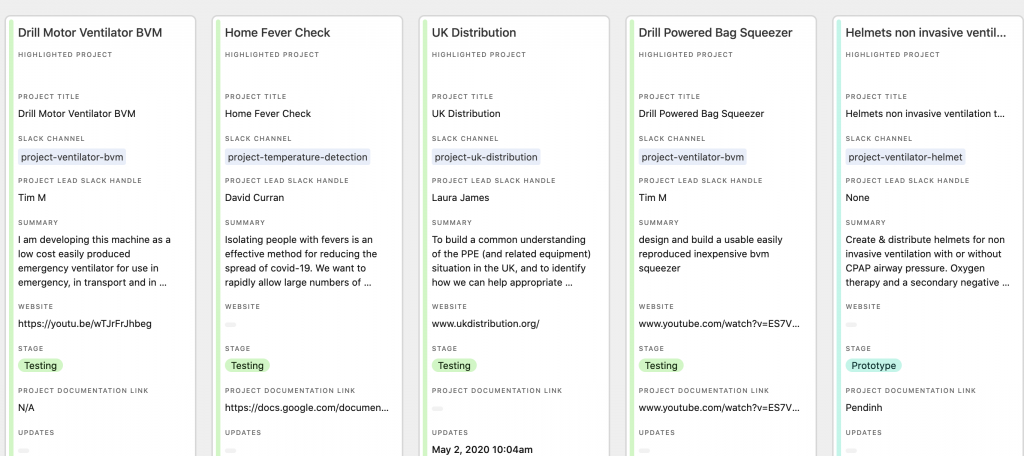

PL0: Tell me about a project or a few that have been big wins for the community.

We have had several great early wins. One of our first supported projects within Helpful Engineering was makermask.org, which produced a PDF design on how to make a mask along with the materials research to make sure it was safe and effective. It has been viewed 21 million times since April and even today is downloaded up to 1,000 times a day. Probably the most important thing about this mask design is that it specified effective materials that any household could get their hands on.

Our second success was the Origami Face Shield – a simple piece of laser cut Polyethylene Terephthalate (PET) plastic that you could make anywhere. It became the inspiration for just about every flat pack face shield you see today, and it is still the cheapest one on the market for its use case at around $1/unit

Another big win was the open standard respirator. It is a silicon injected model that can be chemically bathed for sterilization as needed. Its total cost of operation is lower over time versus a standard respirator, using approximately one-sixth the filtrate of a standard n95 mask It should be a Godsend for both hospitals and civilian populations, and we’re still trying to get this up and made. First articles have been produced. We simply need financing to begin production and get it into sales channels.

Sometimes things can slide without complete regulatory compliance in a crisis. This is especially true of simple items such as a cloth mask. A respirator, for instance, is more complicated and has more complex parts to which the engineering process and proper regulatory oversight must apply just to make sure it is safe and effective. Helpful ensures makers are supported with the right framework and with an understanding of regulatory requirements during their development because our observation is that if things are not made 100% right, there is no point in making them at all. There are a lot of people who have been saying in a crisis like this that “something is better than nothing.” In the case of medical products, that is just not true, and it is why of the millions of donated items of PPE that have shown up at hospitals around the World, the vast majority of them have ended up in the garbage.

PL0: What are the operating principles of Helpful Engineering? How does Helpful achieve success?

Safety leads the way. Everything that Helpful Engineering does, even in a crisis, is done in a manner that emphasizes and maximizes safety, from the design of a solution through the design of its manufacturing process or business process…we’re even committing to a pure information approach in public outreach and awareness campaigns. We approach every solution we design as if we had to defend it to a regulatory body in a clearly describable, defendable format, and we want to remove as much complexity and duplication from the entire process as possible.

Some see Regulatory oversight as a burden, but it’s really not. The regulatory process actually gives you freedom to design as it provides a simple, logical operational framework to explain yourself and how to make something. Regulatory at its essence asks:

- What are you trying to do?

- How are you going to do it?

- How are you going to prove your solution is safe?

When a product comes out the other side of this process, it is a defendable, describable idea and it is credible. Most current “maker” products showing up at hospitals have no process behind their development nor do they have 3rd party oversight attached or proof of efficacy. By producing an open source product development pipeline capable of interfacing with the FDA or EC regulatory process, Helpful Engineering is demonstrating there is a way to deliver safe, reliable, and compliant products in a completely new manner: they can be designed directly by their end users, in collaboration with product development specialists who no longer need to guess at what the user “really” wants. As such, we anticipate a significantly greater degree of product success. Speculatively, because there are relatively low barriers to entry when using our IP and its shared development model, we’re hoping to see an in increase in the number of local small business startups around the world, producing things optimized for local conditions and needs, but producing safer, more durable local economies as a result. Ultimately we think pursuing this shared development model will make for a safer, more durable world in times of crisis.

We’ve learned a few things along the way that suggest this a good model to pursue. For example, take your average medical product. For every $1 invested, a company expects to make around $10,000 on that development dollar. These products are typically on a 3-5 year life span and care cycle. Additionally, a hospital then has to plan to spend between $5 to $10 for every $1 spent on hardware/software on their internal deployment. This is purely to determine if even the FDA-approved device is safe within their physical plant. In this model, the hospitals are not wasting that $. That’s 100% money that is spent to mitigate risk and potential patient harm.

We know a distributed development model can highly improve on these numbers resulting in lower total solution spends, in hardware, software, and support systems, and at the same time we believe we can make them safe, and ultimately accessible to world markets that currently have no path to accessing this quality of patient care.

That’s a big deal and something worth trying to do.

PL0: So for the engineers reading, what’s the best way to get involved?

We need people who know how to accomplish stuff and have the will to do it. Our entire organization – both the Not For Profit as well as the projects we support, are made up of people who are, for lack of a better way to put it, tired both of the way things don’t work as well as waiting for existing business to address the needs of the masses because they only take risk based on the expectation of exhorbitant financial returns.

Well, that attitude means that a lot of people don’t get what they need when they need it because there is an inefficiency of some sort. Our job is to figure it out and provide the best solution we can to address it.

Right now, Helpful itself needs software architects who are willing to learn the vision we are trying to realize, and help establish the executional framework to support the effort. We have a project underway to design and implement a piece of software to tie the community together that will allow volunteers to quickly find tasks they can execute, or obtain education they are lacking in exchange for their contributions.

We work very much with an apprentice sort of mindset. What can you do well? Come do it, and teach someone else how to do it, and see what you learn in the process. We have all the room in the world for people who have curious minds.

Our immediate goal is to be ready for the next surge both of CoVID, where we see the probability that we’ll have an influx of new volunteers in the next few months, but also we want to be able to address other socially impact issues that help resolve systemic risk.

For example, I have had a number of family farmers in the midwest and south reach out asking for sustainable farm equipment. Current business models around farm equipment make the equipment incredibly expensive and not accessible to other LMIC agricultural communities domestic or abroad. They want zero or negative emission tractors, combines, bailers, etc. They do not want to grow corn for ethanol. They do not want equipment that they cannot service themselves. This is something that would be worth us getting into as it may provide one path for us to help people produce a higher quality food supply on a more local, sustainable basis.

We have space and capacity for people to join who want to take on these sorts of problems.

When people make stuff together they get along better because they learn things about each other. They share values and grow understanding and appreciation both for respective needs as well as contributions. This is literally the most productive thing we can facilitate at inception of the design process or when we decide to address an identified need. The worst thing we can do is endlessly bloviate about possible solutions that never get started because the barrier to actually producing a solution is too high.

That is what Helpful Engineering is really about: providing the appropriate scaffolds for people to get started helping themselves to produce what they need, without waiting on others.

PL0: What does the future look like for Helpful Engineering?

Helpful is working with both governmental and international non-governmental organizations on what the future of Open Source design, distributed development, agile manufacturing and supply chain management needs to look like to reduce systemic frictions and risks.

We have reasonable starting points on what future engineering and manufacturing processes might or need to look like. The last time the manufacturing process as such was holistically considered was the WWII era, so it’s due for a bit of an overhaul. Our intention is to migrate these institutions into an extensible framework capable of supporting standards, APIs, specifications, regulation…basically everything you need to make something quickly and safely – into an agile framework for the future. We see huge opportunities in this space. There are so many processes right now that – done manually – a piece of innovation can easily take 1-2 years in product development cycles. It is not unrealistic to assume that by utilizing AI and other available technologies, the same processes could potentially be accomplished within mere days.

Crazy design-think isn’t actually so crazy when you drill down into much of it. There are huge opportunities to create quality standardized component systems that serve as the building blocks for more complex products. Helpful is ensuring that this work is done systematically and to the highest quality, and observes the most challenging use cases. We intend to make everything the same way: as if we were making a medical device.

Engineers are practical people (mostly!). They make stuff. When I was 13/14 I was in a shop class in Wisconsin and you had to learn how to make stuff because if your tractor broke or you had to repair your milking equipment – you needed to do that yourself. Now that I”m in my late 40s, I’ve observed that an emphasis on outsourcing has moved us away from the fundamental concept of self-reliance. I’m not just talking about individuals, though it begins there. I am by extension discussing communities. If people aren’t in the frame of mind of self-reliance, you get a sick population in a certain way. A lack of self-reliance translates to an individual feeling of helplessness. Helpful Engineering very much tries to address this by teaching people how to build what they need in the safest way possible, and for it to be useful to most people. It is empowering on multiple levels.

So this is what we do. Through the resources in our community, we teach people how to make what they need with the idea that they end up with a describable, well thought out product or service that addresses a broad needs case and is both highly defensible as well as meets the needs of all stakeholders. As such, the hope is that it is easier to get it made faster so that it can be useful quickly, reducing risk at every step along the way.

We’d love for engineers and problem solvers of all types to reach out and discuss how to get involved. Skilled software engineers and product developers we can put to work most quickly, but we encourage Engineers in other domains and industries to begin to think about what they might do in a community like Helpful. Perhaps you know about solar? Or battery technology? Or large scale casting? Let’s think about making that farm equipment. That’s not an easy job – but we can begin to get organized and figure out how to tackle the challenge, as well as the path to getting the solutions made.

This is what we are all about. Come join us and see. I think you’ll find it interesting, worth exploring, and worth putting some time into.

Thanks for learning about us!