Check valves are valves that allow for the flow of a fluid in only one direction within a piping system. Their assembly typically consists of an inlet and an outlet and may also be referred to as non-return valves. This article covers the different types, valve construction and components, typical applications, and maintenance and repair.

Check valves utilize the pressure gradient across its assembly to operate, thus allowing flow in only one direction. On the inlet side, high-pressure fluid enters, and on the outlet side, it releases by the inner mechanism at a lower pressure. Once the pressure on the outlet side has become greater than that of the inlet, the valve will close off flow. Because of this operating principle, it is imperative that orients the right way in a system in order to prevent failure in a system. Similarly, the system must operate at a specified pressure in order for the valve to work. This minimum pressure is called cracking pressure.

Types

There are many different types of mechanisms that can constitute a check valve. This section covers some of the main types of check valves used in the industry.

Spring Loaded Inline

Spring-loaded in line valves constitute the most common type of check valve. It operates by allowing flow once the cracking pressure is attained. The high-pressure inlet side must overcome the force of the inline spring to allow flow through the valve, once the pressure has decreased on the inlet side, the spring closes off the valve.

Spring Loaded Y

Spring-loaded Y valves operate off the same principles as its spring-loaded inline. The only difference is the orientation of the spring which seats in a “Y” shape. The Y shape design allows for slightly easier maintenance that its inline counterpart.

Ball Check Valve

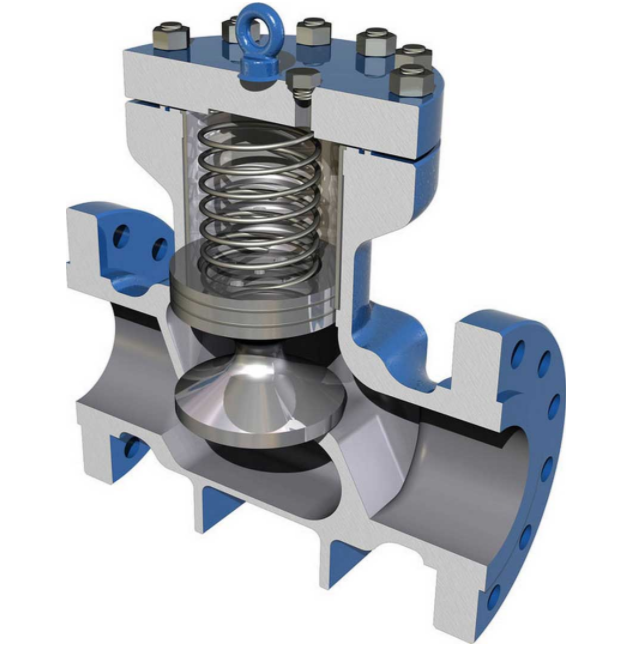

Ball check valves utilize the spring pressure actuation as their spring counterparts. The difference is the incorporation of a ball into the design of the valve whose seating location allows control of the flow within the valve.

Diaphragm Check Valve

Diaphragm valves use a rubber diaphragm to seal flow within the valve assembly. The pressure of the inlet portion must be large enough to deform the diaphragm to allow flow through the valve. They are ideal for low-pressure applications as the rubber may wear out easier for higher pressure applications.

Lift Check Valve

Lift valves operate by the sealing of a disk. The disk is seated so that it moves only up and down and seals properly when closed, the inlet flow must have enough pressure to lift the disk and sometimes a spring that is used to create a higher cracking pressure.

Swing Check Valve

Swing valves are also called tilting disk valves. The inner assembly consists of a hinged disk that swings shut and seals by the force of gravity. Once inlet pressure is high enough, the disk swings open allowing flow. Once the pressure decreases the valve shuts off.

Stop Check Valve

Stop check valves are spring-loaded y check valves that have a manually operated stem. The stem allows for users to keep the flow shut or open, and to even throttle it manually, giving some control over the functions of the valve.

Material Type

Brass or steel provides the most common material of construction. Material selection depends on the application of the check valve. While brass is ideal for most applications, it is often susceptible to saltwater due to its chemical properties. Brass is also not ideal for high-temperature applications as they are not very heat resistant. Steel on the other hand better suits larger, high temperature and pressure applications. For smaller low-pressure water systems, PVC provides an inexpensive and easy-to-use option.

Actuation Methods

The actuation of a check valve is totally dependent on pressure differences. As their design prevents any sort of backflow, the actuation of the valve depends on the high-pressure inlet to overcome the cracking pressure designated by the system. Once the pressure of the inlet has reached the cracking pressure, the valve opens allowing flow to continue through the valve and closes off once the inlet subsides under the cracking pressure.

Applications

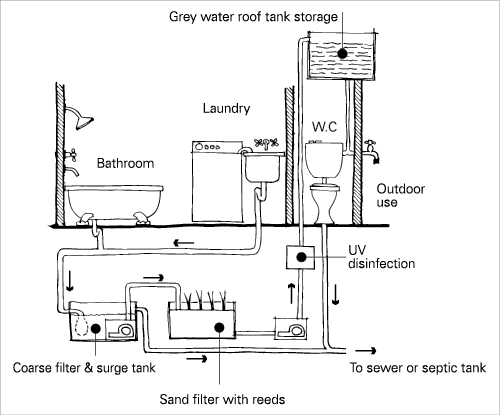

Check valves are prevalent when backflow is a major concern. As the operation of a check valve automatically occurs with pressure changes, any backflow immediately shuts off flow. Any operations where backflow may cause system contamination make check valve specification ideal. Due to their automatic actuation, check valves find use in many applications, from major industrial processes to residential appliances and water lines.

Maintenance and Repair

As the operation of a check valve relies solely on internal pressure gradients, check valve maintenance focuses on the seat, material, and actuation methods. Generally, routine maintenance intervals are performed and ensure the closing device properly seals flow when closed and opens properly at the desired pressure. Any flaws in the seals or sealing devices may cause detrimental backflow. For smaller applications, maintaining a check valve is relatively simple as low-pressure applications require cheaper valves that may are easily replaced. However, for larger systems, scheduled maintenance is crucial in ensuring the longevity and proper operation of the valve within the system.