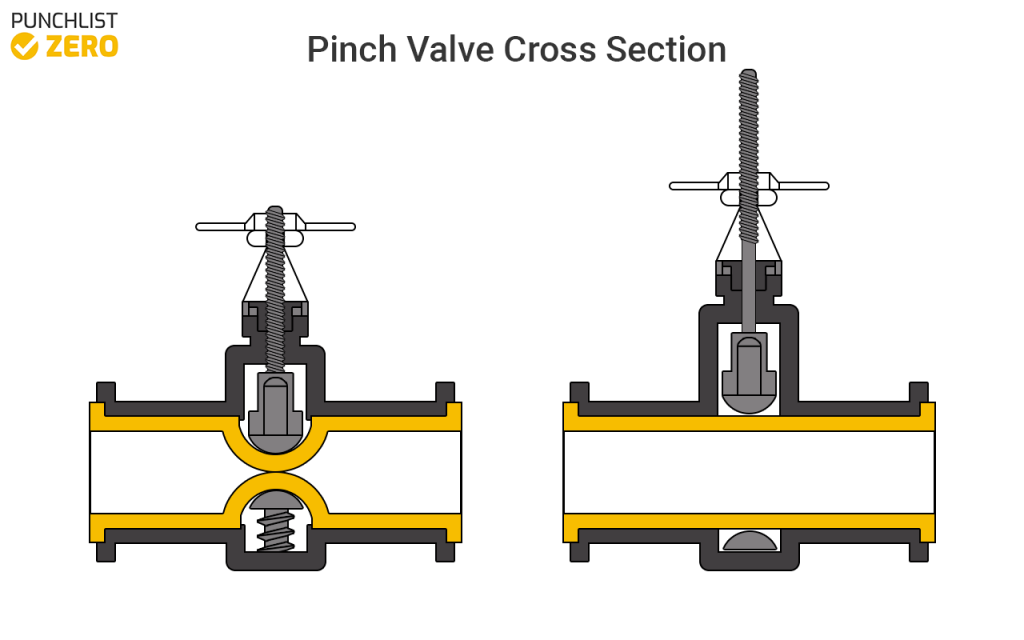

Pinch valves are used to stop or control the flow of a fluid by “pinching” an internal sleeve that restricts flow within a valve assembly and controls it for an entire piping system. The controlling mechanism closes in from the top and bottom of the valve, uniformly reducing flow through the valve. Pinch valves are ideal for slurries that run at relatively low temperature and pressure due to their reliability and cost-efficiency. This article covers the different types of pinch valves, valve construction and components, typical applications, and maintenance and repair.

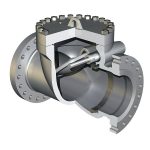

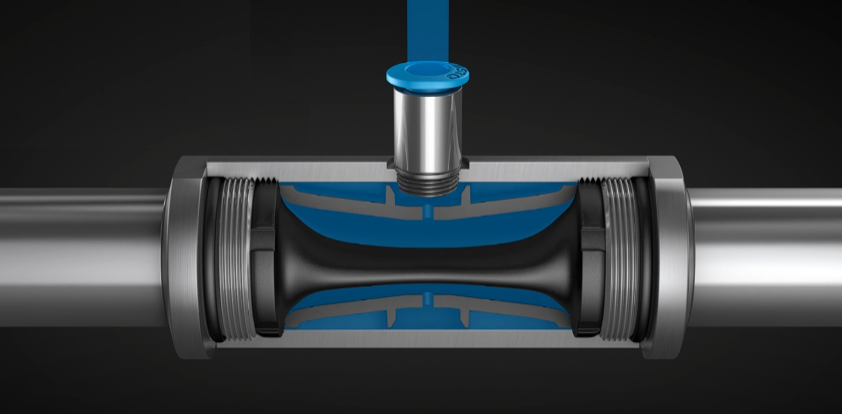

Pinch valves use an internal rubber sleeve to either stop or throttle flow. The sleeve is attached to the main system by flanges and ensures that it is the only portion of the valve contacting the flow. Protecting the sleeve and the main “pinching” device is the housing portion of the valve. Pinch valves are not to be confused with diaphragm valves which close in from only one side as pinch valves close from both sides.

Types

Pinch valves are sorted mainly by the type of mechanism used to pinch the internal sleeve of the valve and the type of stem used to do so. There are also small variations among the methods used to seal the internal sleeve from the start and end of different pinch valves that are usually dependent on the flow characteristics of a system.

The three body types of pinch valves are open-body, closed-body, and pressure-assisted.

Open Body Pinch Valves

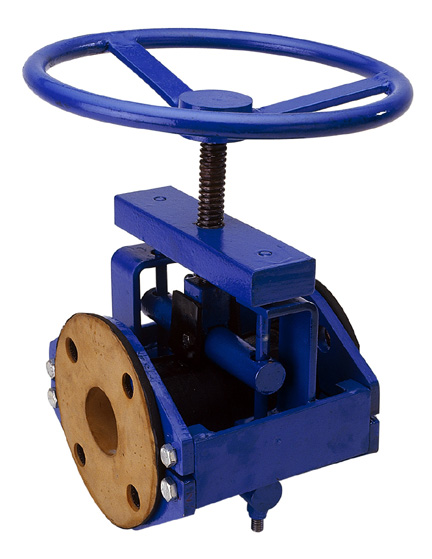

The open body design has no housing around the stem assembly. They leave the sleeve exposed to external conditions that allow for easy inspection but may lead to early failure or contamination of the flow. Traditionally open body pinch valves are inexpensive as they utilize manual stem control and are appropriate for simple systems.

Closed Body Pinch Valves

Closed-body valves encase the stem and sleeve. Otherwise, the system is similar to the open body pinch valve. Similarly they are also relatively inexpensive and applied for less intensive applications due to their traditionally manual stem control.

Pressure-Assisted Pinch Valves

Pressure-assisted pinch valves utilize a fluid inside the main housing to pinch the internal sleeve and shut off flow. This body type has no stem and relies on a separate line to bring in the controlling fluid. This type of body can only be used to turn flow on or off and has no throttling capabilities. They are typically used in more intensive applications are usually the most expensive type due to their strict design requirements.

Material Type

Materials to consider for the construction of a pinch valve include that of the internal sleeve, the stem, and the main housing. The internal sleeves must be made from rubber or plastic to withstand the abrasive force of the flow. They must also be flexible enough to be pinched and deformed by the stem for the lifetime of the valve.

Generally, the housing and stem material are of little importance so long as they can withstand the conditions of the system as most pinch valves are “non-wetted” meaning the internals do not come in direct contact with the flow. However should the valve be “wetted”, the stem and body exposed to the fluid within the system, appropriately corrosion resistant material should be considered especially when dealing with slurries.

Stem Type

Pinch valves typically rely on the use of stems for controlling the flow within a system. The only case in which a conventional stem is not used in a pinch valve is for the pressure-assisted body type.

For all other purposes, there are four types of stems: outside stem and yoke, rising stem with inside screw, non-rising stem with inside screw, and sliding stem.

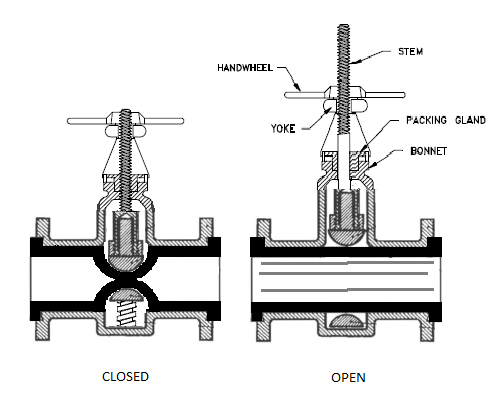

Outside Stem and Yoke

The stem is threaded and makes contact with the outer portion of the housing to tighten and contact the internal sleeve. This allows for manual control of the flow and is traditionally found on an open body pinch valve.

Rising Stem with Inside Screw

The stem is threaded and makes contact with an inner portion of the main housing to tighten and contact the internal sleeve. As the valve opens, the stem rises, allowing the flow to continue. When the stem goes down, the valve shuts off.

Non-rising Stem with Inside Screw

The stem turns to restrict or allow flow but does not move up or down. The inside screw is used to apply pressure to the sleeve to control the flow within the valve.

Sliding Stem

In the sliding stem design, a stem slides inside the valve to control flow. This action can be controlled manually or through hydraulics. They utilize no screws and have no turn to them, they simply slide up or down to shut off flow.

Actuation Methods

The actuation of a pinch valve deals with controlling the shut off of the flow, which is usually controlled by the stem of the valve. The pinch valve stem may be controlled through five usual methods: manually, solenoid-operated, electrically, pneumatically, or through the use of hydraulics. Actuation is dependent on the type of pinch valve used as well as the application of the system. For larger processes electronic or solenoid operation would be the best fit, whereas small-scaled systems may only require manual stem operation or even solenoid based pinch valves.

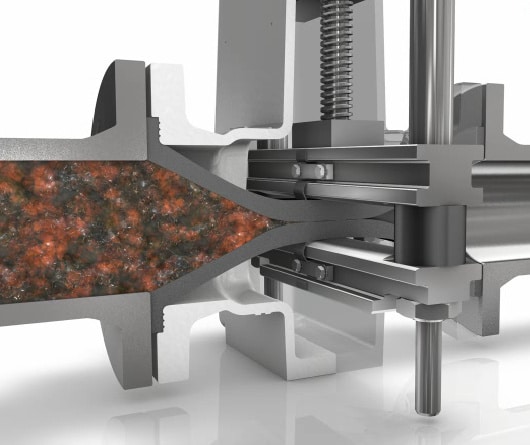

Applications

Typically pinch valves are ideal for slurries which are semi-liquid mixtures containing cement or any other sediment mixed with water. The abrasive nature of slurry flow is well addressed by the internal sleeving of the pinch valve. As these valves have no contact between the controlling mechanism and the flow, they can be used where contamination of flow is a concern. A potential drawback of pinch valves is the tendency of the typically rubber made inner sleeving to deform under high temperature and pressure flows. In such applications, a pinch valve sleeve is not ideal.

Maintenance and Repair

Pinch valves are relatively inexpensive and low maintenance when used for the recommended systems. Pinch valves utilizing the open body style are far more convenient for regular maintenance and inspection of the internal components to ensure proper operation. They are also known for very clean operation as the internal sleeve securely seals the system. On the other hand, pressure-assisted pinch valves are the ideal choice for intense flows. Along with their strong operating performance, pressure-assisted pinch valves offer relatively few maintenance concerns.