The flame arrestor, sometimes spelled as flame arrester, is a device that connects to a piping system that allows gas, liquids, etc. to flow through it while ceasing the entry of flames. It contains a group of screens, perforated plates, slots, or other geometry that absorb and extinguish the heat of the flame passing through. This prevents the spread of large fires and minimizes the impact of events of explosions. In this article, you’ll learn about the functions of the flame arrestor, types, and application considerations.

Operating Principles

The flame arrestor provides immediate protection against unwanted explosions. Equipment providers use a variety of flame arrestors, particularly when flammable vapours are present and when explosive atmospheres may possibly occur. Often, industries such as petrochemicals, shipping, refining, oil exploration, etc. require handling and storing of flammable substances and mixtures, thus their operations greatly require the use of these devices.

Unforeseen flaming of any combustible mixture results in the accidental production of flames. Flames travel along the media’s path and consume all available fuel. By specifying the right flame arrester, quenching of flame occurs prior to rapid increase in the volume of the unstable gas mixture. The failure to control this increase will accelerate the spread of flame which is gravely threatening for this may result to large fires or worse, catastrophic explosions.

Flame Arrestor Types

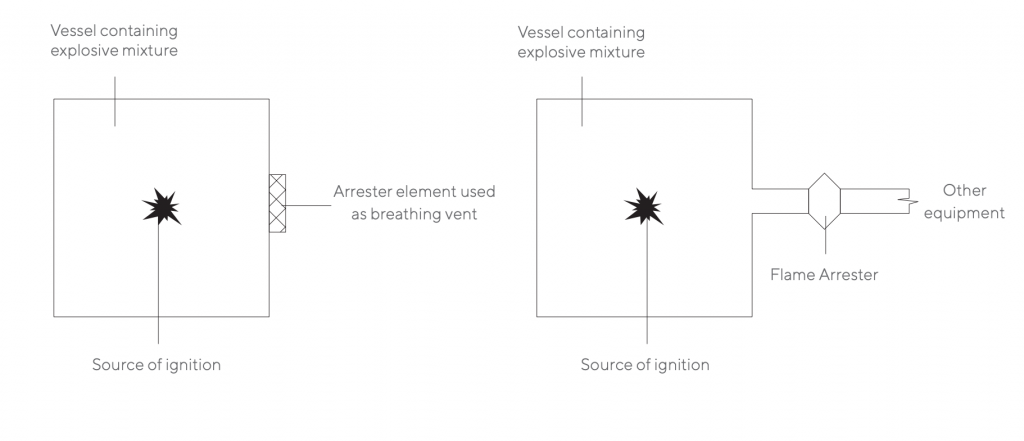

Flame arrestors generally allow liquids and gases to pass through while quenching heat and preventing flames from precipitating huge destructive fires. Applying this principle to arresters specifcation results in three different types: end-of-line, in-line, and pre-volume flame arrestor.

End-of-Line Flame Arrestor

The end-of-line flame arrestor, also known as Vent-to-Atmosphere Flame Arrester, fastens onto the end of a vessel or a pipeline. It prevents the entry and escape of flames from the vessel or pipe. It absorbs heat with the use of spiral crimped wound ribbon constructed of stainless steel. The inverted mounting of this end-of-line flame arrester is not recommended for the heat would likely be trapped and may cause flashback.

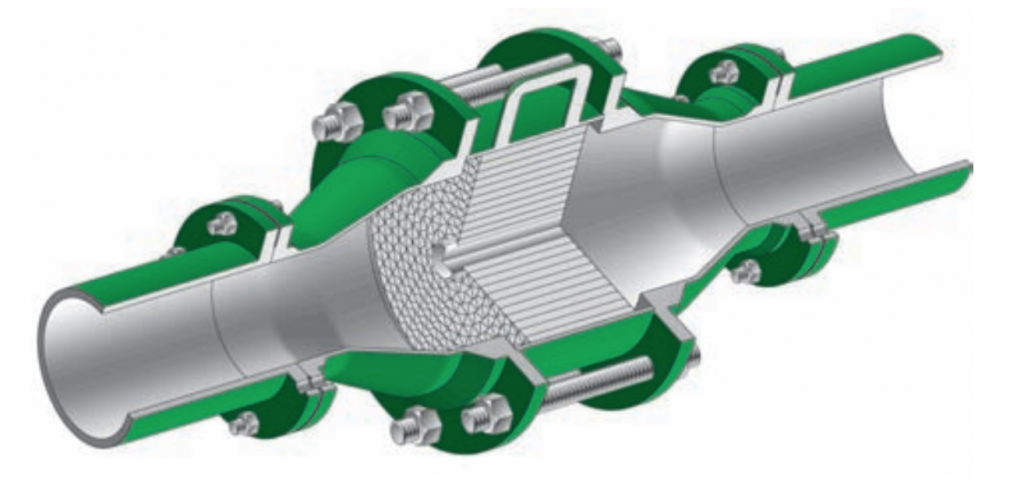

In-Line Flame Arrestor

This next type of arrestor can either be a deflagration or detonation type of arrestor. Deflagration means abrupt oxidation that propagates at a velocity less than that of sound in air. Detonation means abrupt oxidation that propagates at a velocity up to five times the speed of sound in air. Both kinds protect downstream equipment from a possible explosion within a piping system.

Pre-Volume Flame Arrestor

The type of flame arrestor prevents flames from within the system that may flare up the surrounding area. This type of arrester design mainly blocks the flame from leaving the container to prevent it from causing more damage.

Application Considerations

Fitting the appropriate arrester to the applications requires the consideration of a number of factors.

- Analyze the vapor. The proper design and material of flame arrester depend on the type, density and molecular weight of the subject vapor. Engineers should understand the vapor makeup or conduct a vapor analysis prior to specifying an arrestor.

- Probable span of an arrester’s service. The service life of an arrester depends on the subject gas mixture and material of construction.

- Connection type. The position and function required by the arrestor determine the type chosen.

- Pressure range. The range of working pressure determines whether the arrester can effectively quench flames in all conditions.

- Flowrate. The flowrate should accurately be calculated in volumetric terms by first checking the tank type, dimension, filling and pressure rate.

Flame arresters require periodic inspection to ensure they are free of containments, insects, dirt, and corrosion. In 2006, The United States Chemical Safety and Hazard Investigation Board concluded that a badly corroded and uninspected arrestor failed to prevent a 2006 wastewater treatment explosion.