Heat exchangers are a common piece of industrial equipment. Knowing when to specify heat exchangers as well as design and construction details is a highly valuable skill. This article reviews the application, design, and construction details of industrial heat exchangers.

Practical Use of Exchangers

Heat exchangers are common pieces of equipment to exchange heat. They are found anywhere from home refrigerators to refineries in power plants. Heat exchangers are a good fit when cooling a media is required or hot media already exists that can be purposed for heating.

Heat exchangers can’t directly be used for boiling or freezing. When spot heat or highly controlled heat is needed, electric heaters are usually a better application.

Design of Heat Exchangers

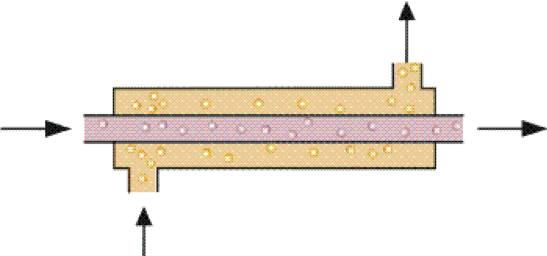

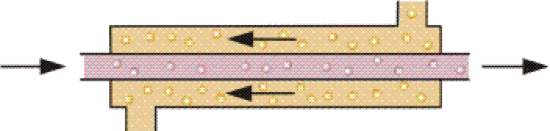

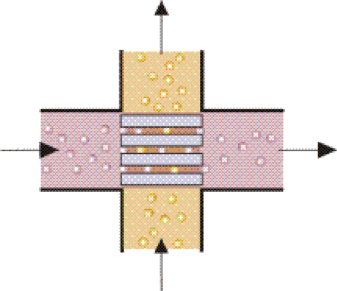

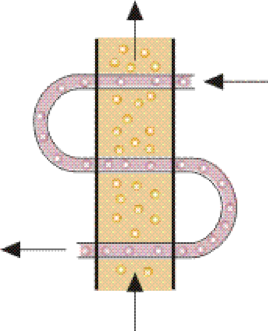

Heat exchangers can first be categorized by their flow configuration design. Flow configuration designs are based on the direction in which the fluids move. Here are four designs of heat exchangers based on their flow arrangement.

Cocurrent Flow

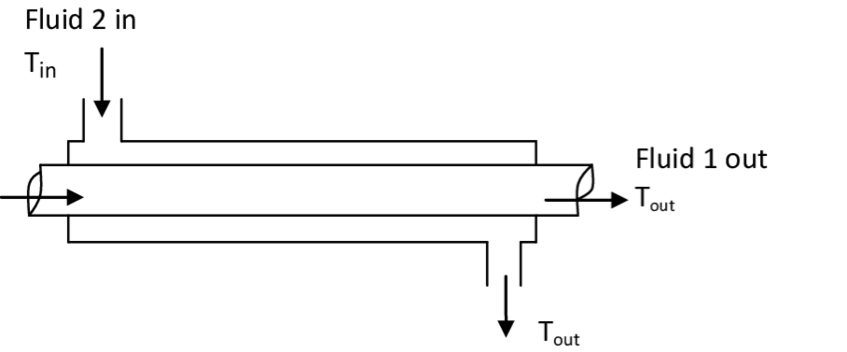

Fluids move parallel and in the same direction in heat exchangers based on cocurrent flow design. Engineers may also call them parallel flow heat exchangers. This configuration allows the best thermal uniformity in wall temperature, but it’s not an efficient design.

Countercurrent Flow

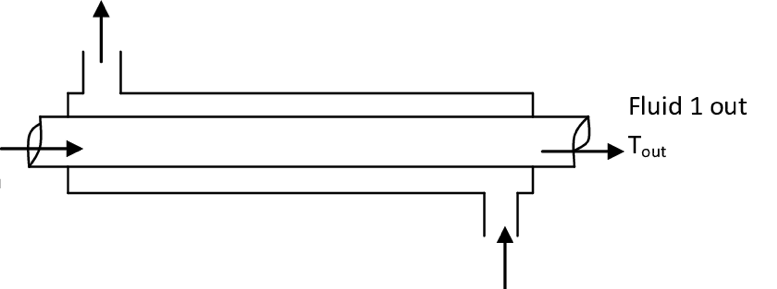

In countercurrent flow, fluids flow in opposite directions to each other . Despite this singular difference, it offers the best efficiency with the highest change in temperature. It’s the most commonly used flow configuration in heat exchangers due to its simple design and great performance.

Crossflow

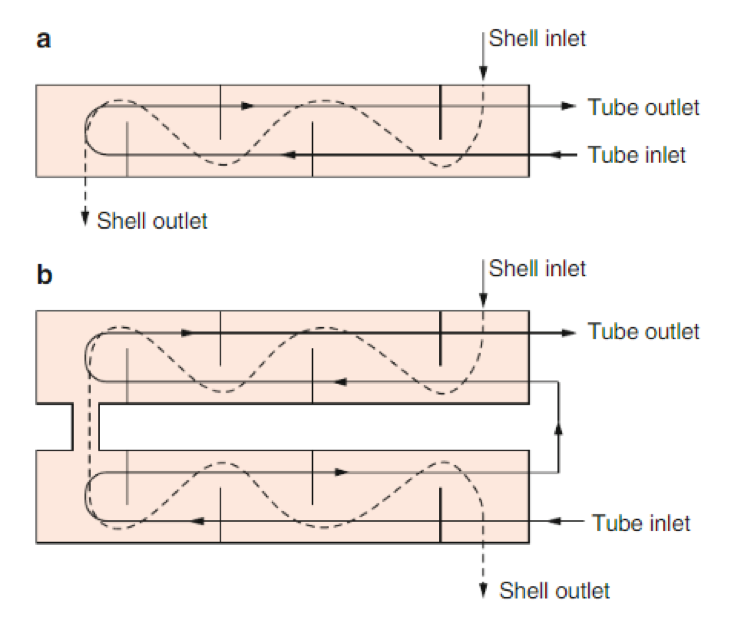

Both fluids flow perpendicular to each other in crossflow design. Its efficiency is not as good as countercurrent, but it’s better than cocurrent. This design has two further classifications.

- Mixed Flow: Fluid temperature is equalized

- Unmixed Flow: Fluid temperature is equalized

Hybrid Flow

Hybrid flow design is a mixture of all other configurations. These heat exchangers can employ both crossflow and crosscurrent arrangements within one setup. This configuration is usually used to cover the limitations of an application.

Types of Heat Exchangers

The design concepts expressed above are practically expressed in the physical construction of a heat exchanger. Broadly grouped, the three major types of heat exchangers are: shell and tube, plate and frame, and tube and tube.

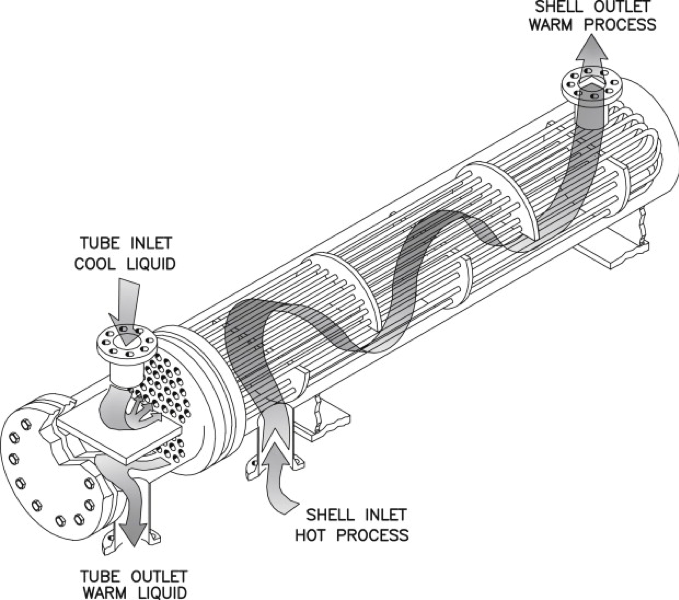

Shell and Tube

Shell and tube heat exchangers constitute of a cylindrical shell and tube bundle. The shell can be vertical or horizontal and also may be categorized as U-tube, floating head, and fixed head. The tube part of the exchanger has a large number of small tubes that are carefully threaded into a positioning plate, also known as a tube sheet. The plate is then positioned into the cylinder using a tube stack. It is designed in such a way that one fluid flows around the other in tubes with a sealed shell between them.

Shell and tube exchangers have four main connections: two inlets and two outlets. Their design is flexible, as pipe size, diameter, pitch, and pipe arrangement can easily be altered.

Shell and Tube Advantages

- As they are versatile, they can meet almost any heat-transfer requirement.

- They can provide a large amount of heat-transfer with very few connections.

- There is no dimensional limit.

- The equipment to build heat exchangers is available in a typical fabrication facility. This allows for custom-designed units easily.

Shell and Tube

- The amount of non-destructive testing required to find leakage can be excessive as it is difficult to find spillage when a problem is incurred.

- Tubes are prone to fouling. Fouling is the clogging of the interior of the tube which reduces heat transfer effectiveness.

- Heat exchange is not as effective as the plate and frame unit.

Plate and Frame

These heat exchangers are made of thin corrugated plates on a frame, hence the name: plate and frame. It creates high wall shear stress and turbulence to transfer heat. Plates are attached using laser welding or brazing and work as a channel for only one fluid to flow.

Unlike shell and tube, plate and frame only has the countercurrent flow configuration. So when one fluid is flowing up in one plate, the other fluid is flowing down in the other. There are four main types of Plate and Frame heat exchangers with some variations.

- Gasketed Plate

- Brazed Plate

- Welded Plate

- Semi-Welded Plate

Advantages of the Plate and Frame

- Tie-in bolts can be removed easily allowing for access to the machine. This makes these exchangers easy to inspect and clean.

- Plate and frame exchangers are expandable. Depending on the design, additional plates may be purchased instead of an entire new assembly.

- High heat transfer co-efficients lead to smaller surface areas, which result in a smaller footprint and cheaper auxiliary equipment.

- The plate pattern, many contact points, and narrow plate gap results in very high turbulence. This results in low fouling.

Disadvantages of the Plate and Frame

- The geometry of plates can’t accommodate high pressure and temperature, limiting its use to moderate temperature applications.

- As their flow path is small, they are not suitable for gas-to-gas heat exchange and fluids that contain suspended solids.

Double Tube

Double tube heat exchangers are designed in a way that one pipe is held inside another. One fluid flows inside this inner pipe, acting as a conductive barrier, while the other flows around it in the outer pipe. They typically only use the countercurrent flow configuration. The pipes are usually doubled back make to the unit more compact.

Advantages of the Double Tube

- Removal or addition of units as per project or client requirements is easily done.

- They are very well suited for high-pressure applications due to their design, and they are easy to build and operate.

Disadvantages of the Double Tube

- They require a surface area of less than 50 m2, limiting the use to only low heat duties.

- As the number of units increases, the possibility of leakages also increases because of the connections.

Air Cooled Exchangers

At times, it may not be practical to use a cooling or heating medium that employs conduction as its primary source of heating transfer. In those instances, a naturally cooled or fan-cooled exchanger is used. The primary heat transfer method may either be free convection (exposed to ambient air) or forced convection (fan driven).

Advantages of the Air Cooled Exchanger

- The air-cooled exchanger does not need piping runs or a cooling water supply.

- The power use is insignificant compared to water-cooled options.

- Use of this type of exchanger is practical for high-temperature process systems.

Disadvantages of the Air Cooled Exchanger

- Heat transfer is much lower than other types of exchangers.

- Typically a large footprint is required to properly expose the exchanger to air cooling.

Boilers, Condensers, and Others

These heat exchangers are specialty exchangers created to serve a particular function. Boilers allow a fluid to be boiled, while condensers compress a vapor into a fluid. Boilers and condensers are designated when a phase change is required.

Heat exchangers are defined as a device used to transfer heat from one medium to another. As such, various other configurations are used in the industrial equipment industry. Two such examples are the adiabatic wheel and the waste heat recovery unit, but other configurations are possible depending on specific process requirements.

Maintenance Considerations of Heat Exchangers

Regular exchanger use will affect performance, potentially even necessitating a replacement. To maximize exchanger life, the following practices should be followed:

- Consider the use of a low-viscosity and high-purity high transfer fluid. Using high purity fluid will help avoid coking and aging of the internal pipework and reduce the thermal degradation.

- Adopt a habit of regular maintenance and servicing to continue a safe and efficient performance.

- To slow down the thermal degradation, reduce the operating temperature.