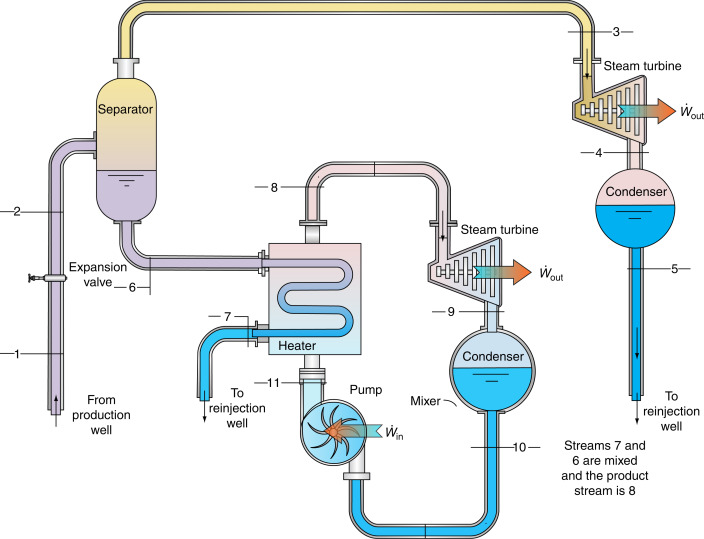

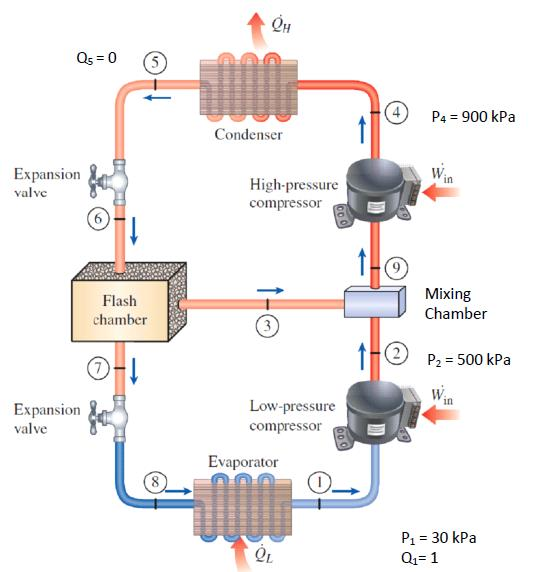

A flash chamber is a device that separates liquid and vapor refrigerant. It fits into the line after the expansion chamber, sending only liquid refrigerant to the evaporator and vapor to the compressor. The flash chamber provides a potentially important design element as part of the refrigeration cycle.

In this article, you will learn about the purpose of a flash chamber, its use in refrigeration, its use vs. flash tank, and vapor injection.

Purpose of Flash Chamber

A flash chamber separates liquid from vapor. This insulated container uses centrifugal force to keep moisture out of the evaporator. The evaporator receives only the fluid and delivers the vapor straight to the compressor. Flash chambers improve performance in refrigeration cycle applications.

A flash intercooler sets in between the condenser and the evaporator. The VCRS (Vapor Compression Refrigeration System) cycle may employ multiple flash chambers. This allows a gradual step-down of pressure while achieving maximum liquid flow through the evaporator. Design is tightly controlled, typically by an OEM who produces the entire refrigeration process.

Generally, only low-pressure and low-temperature fluid should flow through the evaporator tubes. This reduces the likelihood of busting or premature erosion. The liquid also possesses a higher heat transfer rate than vapor. Also, moisture compresses to the pressure rating in the compressor if it is not delivered to the flash chamber.

To conclude, this device’s ability to separate vapor from liquid increases the system efficiency.

Flash Chamber Use in Refrigeration

Flash chamber’s most common application occurs in multistage refrigeration systems. They install between the expansion valve and evaporator coil. Refrigerant generally stays in a liquid state due to the rejection of latent heat in the condenser coil.

The expansion valve alleviates pressure. Applying the ideal Gas law (PV=nRT), it follows that temperature also drops during this process. Some of the liquid refrigerant convert to vapor. If this vapor carries into the evaporator, efficiency drops. This efficiency drop results from a reduction in the contact surface between the liquid refrigerant and the internal evaporator surface.

Separating the liquid refrigerant from vapor improves the evaporator coil’s efficiency. This occurs in the flash chamber. Using it in a VCRS provides some advantages. This includes the lack of need to compress the already high-pressure vapor to the same pressure from evaporator pressure to the pressure of the flash chamber. Also, better heat transfer rates in the evaporator occur.

As a practical implication of this, the evaporator’s size may decrease. Thus, while theoretically, the co-efficient of performance shouldn’t increase with the addition of a flash tank, practically the losses decrease with the addition of an appropriately sized one. This results in more efficient refrigeration.

Flash Tank vs. Flash Chamber

The flash tank generally refers to a much larger vessel. It allows for a greater amount of vapor-liquid mixture than the flash chamber. Flash tanks reduce steam pressure in a boiler prior to the mixture going to boilers, condensate tanks, or a drain.

The design and build of flash tanks occurs in accordance with ASME Section VIII, Division 1. This means the flash tank is a code pressure vessel. Generally, the flash tank’s length should be about twice as long as its diameter. For example, for a 5′ tank diameter, the length would be 10′.

Vapor Injection

Vapor injection into the flash chamber notably improves system performance in extremely low and high temperatures. Several studies have investigated this phenomenon in greater detail. Wang (2008) conducted a series of testing with vapor injection into a flash tank cycle. He reported a maximum capacity and co-efficent of performance improvement of 33% and 23%, respectively, when the ambient temperature was -18°C.

Flash tank vapor injection requires a strong control strategy to maximize efficiency. Doing so has proven to be a challenge for researchers and engineers alike. This can be attributed to drastically changing and difficult to model conditions when referigerant presents in a liquid-vapor phase.