There is a lot of misunderstanding about the service factor concept in the industry. Some take it to be solely a periodical excursion into overload conditions, while others consider it an allowance for permanent overdrive. Neither of these assumptions is 100% accurate, so there is a need to take a closer look at this important concept. In this article, you will learn more about the service factor, and its application in gearboxes and motors, and compare service factor vs power factor.

More on Service Factor

According to NEMA, service factor (SF) is a multiplier that is applied to a power rating to indicate a permissible amount of overload on a device. However, this applies only under certain conditions. These conditions include preset values for variables such as voltage, frequency, altitude, temperature, and pressure.

Thus, if the nameplate of a device shows a service factor of 1.15, it does not mean that it can run at 115% of its rated load all the time. Rather, it shows the device’s ability to run above its usual capacity just to meet certain demands. After this time, it should return to its normal operating capacity. The essence of SF is to:

- Handle any occasional or intermittent overloading in a system.

- Compensate for low, or unbalanced supply voltages.

- Permit for temporary operation beyond the normal ambient conditions.

- Meet sporadic surge in needs for horsepower.

Unfortunately, due to the lack of definition of the temporary period, it is easy to abuse the SF by overrunning the device. The performance and integrity of the device then deteriorate over time.

Application of Service Factor

The concept of service factor (SF) is important in almost all machinery, especially motors, and gearboxes.

Application in Motors

Determining the right amount of load for an electric motor is key to defining its service life. The performance of motors decreases when loading is less than 50%, as well as during overloading.

Thus, designers should aim to load motors to around 75% to 80% of the rated load, where motors are most efficient. Service factor applies to this design factor as it accommodates oversights in the prediction of horsepower needs and handles occasional overloads.

Also, the service factor enables the motor to operate when parameters such as temperature and voltage are outside its design range. Due to the SF, a motor can function continuously below the maximum load, so that its winding temperature is cooler.

Cooler temperatures are important in motors because running continuously at 20°F above its normal temperature may reduce its lifespan by up to half. In any case, using a motor at service factor for long periods causes:

- Failure in bearings due to overheating.

- Potential winding and its insulation failure as temperature remain consistently high.

- Insufficient starting or operating torque.

- Inefficient use of energy.

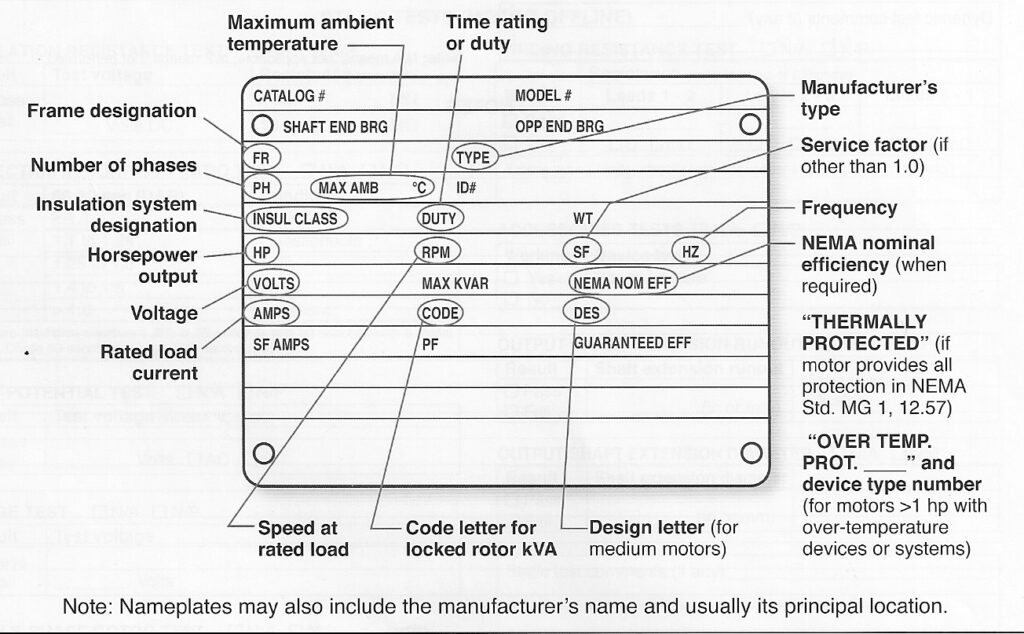

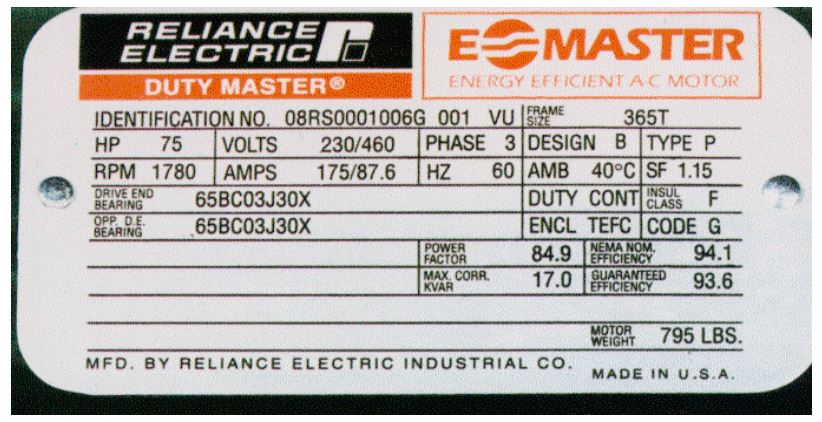

As a result, users must never rely on the service factor capability to carry the load on a motor on a continuous basis. Furthermore, if the SF of a motor exceeds 1, standard practice requires it to be on the nameplate as indicated in the figure below.

Application in Gearbox

Determining the appropriate service factor for a gearbox is one of the first steps in sizing it. Moreover, its value is the ratio of the gearbox-rated horsepower to the required horsepower of the application. Alternatively, the ratio of the gearbox torque to the required application torque can be used to find its value.

This means that the SF value is very specific to the combination of gearbox attributes and application. For example, in industry, it is established that an increase in the gear tooth durability is proportional to the service factor. As such, if tooth life increases up to 10 times, the SF may increase by 30% and vice versa.

Sizing a Gearbox

Generally, evaluating the service factor values of a gearbox starts with examining tables and charts from the manufacturer. These charts contain details on types of bearing, application, and service duty levels. A service factor is recommended depending on the combination of these details on the chart.

Because the service factor for a gearbox serves as a safety factor, it is also dependent on the operating conditions. When certain conditions are present, there is a need to increase the service factor. Some of these conditions include:

- Presence of non-uniform loads.

- Vibrations or extreme shock loads.

- Cyclical loads.

- Elevated temperatures.

After increasing the service factor based on the operating condition, multiply it by the application horsepower to obtain the required gearbox horsepower.

However, the influence of the service factor is less when sizing gearboxes that are used in servo systems. This is because the output torque, speed, and inertia are more critical for the proper operation of the system. This is why some gearbox catalogs do not contain service factors.

Service Factor vs Power Factor

Both service factor and power factor are important parameters in any machinery. They may appear similar but are not the same as the table below highlights.

| Service Factor | Power Factor |

| It is a multiplier that is applied to a power rating to indicate the amount of permissible overload. | The power factor is an expression of energy efficiency in a system. |

| Mathematically, it is expressed as the ratio of design power to motor power in a motor. While for a gearbox, it is the ratio of the gearbox torque to the torque requirement of the application. | It is the ratio of real/working power to apparent power. |

| Values are 1.0 or above. Alternatively, it is expressed as a percentage above 100%. | Lies within the range of 0 and 1.0, or 0% and 100%. |

| Service factor indicates the ability of a device to operate above its capacity. | Power factor indicates the ability of a device to perform according to its capacity. |