In fabrication, metal pickling refers to a metal treatment process that reduces impurities on the surface of a metallic object. The pickling process removes the surface impurities, such as stains, rust, or other contaminants from ferrous metals, aluminum, copper, gold, and other precious metals by dipping them in pickling liquor. In this article, you will learn the process of pickling, treatment considerations, and the advantages and disadvantages of pickling.

The Process of Pickling

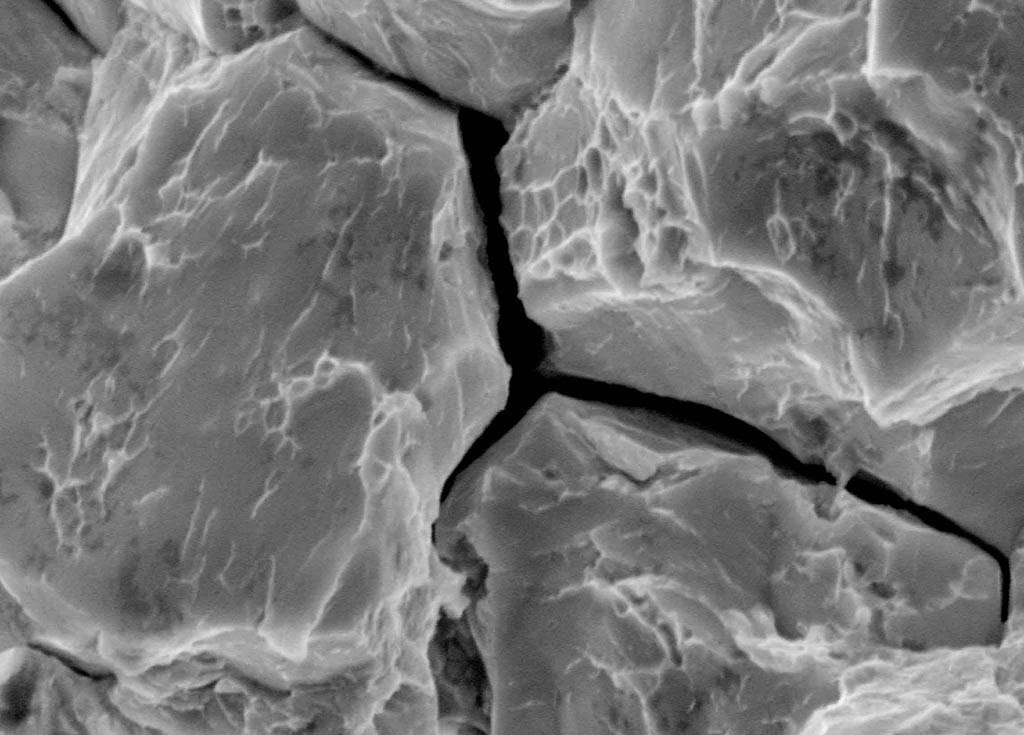

Newly produced metals often contain a layer of impurities on the surface. For instance, hot-rolled steel contains an oxide layer. Welding heats steel to high temperatures forming a colored oxide layer. These oxides impede a smooth and clean surface on the steel object. There are several ways to clean the oxide from the surface of the steel, but pickling provides a simple and effective solution. When pickled, the acidic pickle liquor removes the surface oxide layer without harming the steel object.

Pickling most commonly cleans steel surfaces. The pickle liquor, full of strong acids, removes the surface impurities as part of an overall manufacturing process. The exact composition of the pickle liquor depends on the type of metal. Carbon steels, with an alloy content of less than 6%, are pickled in hydrochloric or sulfuric acid. But for steels with an alloy content of over 6%, a second step of dipping in nitric, phosphoric, and hydrofluoric acid becomes necessary.

For rust and acid-resistant chromium-nickel steels, a dip in hydrochloric and nitric acid provides better results. Dilute sulfuric acid provides pickling for copper alloys. Brass metal requires sodium chloride mixed in concentrated sulfuric and nitric acid for effective pickling. Specialized applications require solutions other than nitric and hydrofluoric acids. Pickling pastes provide better options than liquids in weld joints and crevices.

Even if a piece of metal doesn’t have an oxide layer on its surface, it still probably contains some surface impurities that may be inorganic compounds or trace metals. Depending on the metal and its application, these impurities may reduce its effectiveness. Pickling can remove most impurities due to the strong reactive properties of pickle liquor. ASTM A380 details the standard practice for cleaning, descaling, passivation, and pickling treatments of stainless steel parts.

Treatment Considerations

Pickling solutions have very strong acids that are dangerous both for the operator and the environment if not correctly managed. As an acid treatment, pickling removes contaminants, but does not remove grease or oil. Thus, it may be necessary to use a detergent or alkaline solution for cleaning prior to pickling.

After the process is completed, it is necessary to remove all acids thoroughly by rinsing the object. Neutralizion of the acid with an alkali prior to the rinsing step may be required. Residual hydrofluoric acid may result in pitting corrosion. Post pickling, long exposure to humidity may cause oxidation. To counteract this, operators apply a film of oil or other waterproof coatings.

Advantages and Disadvantages of Pickling

Advantages

When performed on a metal object, pickling creates a clean and smooth surface. Pickling provides an economical, simple, and effective method to treat metal surfaces. The pickle liquor has strong reactive properties which remove the surface impurities resulting in a cleaner and smoother surface.

In the case of sulfuric acid, the same acid can be recycled multiple times by removing the dissolved ion salts in a continuous process. There are other finishing processes for the surface treatment of metal objects but none of them offer the same level of quality and uniformity as pickling. Pickling doesn’t leave marks and blemishes or uneven areas surfaces.

Disadvantages

Pickling creates many waste byproducts as the waste sludge consists of acidic and metallic salt compounds. It is classified as hazardous and requires special disposal.

In some cases, pickling may degrade the physical properties of metal. This is because there is a chemical reaction between the metallic iron-producing hydrogen. Hydrogen may embed in steel via diffusion causing hydrogen embrittlement, making the steel light and brittle.

With the use of sulfuric acid, in the pickling of steel, large consumption of acid is inevitable. Also, a considerable amount of metal is lost in the pickling process although the use of acid inhibitor can reduce this considerably.

In the pickling process, the chemical reaction generates hydrogen gas. This hydrogen accumulates into the steel causing hydrogen embrittlement, and thus deteriorates the mechanical properties of the steel.

Pickling of steel also produces large amounts of waste acid solution and iron oxide. It requires a large investment to recover and utilize these waste acid and iron salts. For some small quantities of steel parts pickling treatment, often the pickling liquid waste treatment is ignored which causes serious pollution damage to the environment.