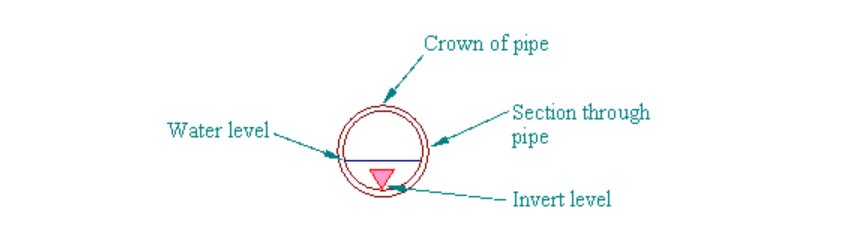

Invert level is the vertical distance between the lowest point of the interior surface of a flow channel and an arbitrary datum. Generally, the location of this arbitrary reference is below the invert, so the invert level measurement is usually upwards. Inverts are important in the design of passages that interact with flow including pipes, manholes, culverts, etc. In this article, we discuss the importance of invert level in the design of flow channels such as pipes, culverts, and manholes.

Role of Invert Level in Piping Systems

Invert level is an important consideration in the design of piping systems, especially those that are reliant on gravity flow. When designing such systems, it is necessary for flow to remain positive in all sections. What this implies is that the invert level at the outlet of any pipe section should always be higher than the following pipe’s inlet.

When located incorrectly, inverts may result in flooding, clogs, and poor drainage. This is why architects and engineers are keen on including piping dimension details in construction drawings for sanitary, stormwater, and HVAC systems. In addition, the relative invert level of pipes in a building is what governs the slopes of individual pipes.

The importance of pipe invert level also cuts across to force flow systems where pumps or compressors drive flow. Although it is not as critical in comparison to its role in gravity systems, invert level influences the selection of the size and location of a pump.

This is because the invert elevation is directly proportional to the pressure requirements on a pump. As elevation increase, so does pump head and the demands on the piping. Having a lower elevation minimizes pumping requirements and enables driving the fluid over longer distances.

Invert Level in Culvert Design

Culverts are tunnel structures that channel water through an obstacle, usually roadways or railways to provide cross-drainage. Generally, these tunnels have a pipe or box shape and could affect the waterways in the following ways:

- Reduce the capacity of aquatic life movement.

- Limit the amount of flora and fauna habitat in the vicinity.

- Increase erosion risk because of flow concentration.

- Result in blockages or damage due to debris.

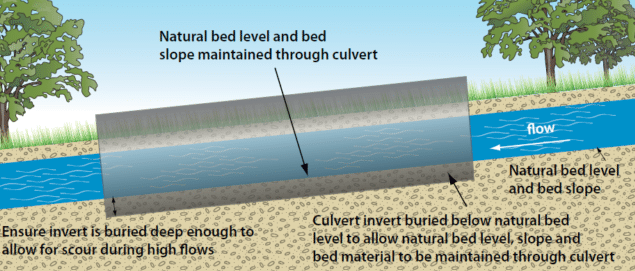

All these undesirable effects are a result of a change in the natural bed level and slope of the flow channel. However, by carefully locating the culvert’s invert to maintain the natural slope and bed level, these effects can be minimized. The measures to attain this goal vary in line with guidelines from the local environment and construction authority. An example of some of these guidelines include:

- The invert for box culverts shall be at least 600mm below the design bed level. In the case of large pipe culverts (> 900mm) the invert shall also be 600mm below the bed. Whereas, small pipe culverts (< 900mm) shall be 300mm below the existing bed level. At no point should the invert of a culvert be above the hard bed, even if the channel is recently dredged.

- Only suitable inert material should serve as a filler for voids between the culvert invert and the existing bed level. If possible, use only the existing bed substrate.

- Avoid the use of a large box or pipe culvert if it results in excessive siltation. In such a situation, give consideration to using multi-stage channels.

Importance of Inverts in Manholes

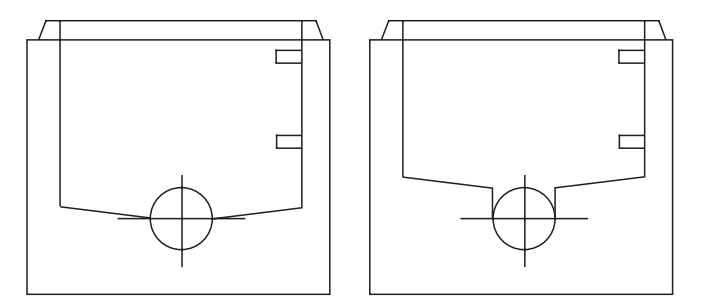

A manhole is an access chamber that operators use for inspecting, cleaning, rodding, and unblocking a drainage system. Concrete is a common material for the manufacturing of manholes, and this process could either be on-site or pre-cast. Despite the method in use, one important feature is the invert level of the incoming and outgoing channels. The location of these invert levels determines the slope of the channel within the manhole.

In addition, the quality of the manhole benching should promote fluid flow at self-cleaning velocities. This prevents debris from easily clogging up the channel thereby minimizing the need for human intervention. With this design requirement in place, drainage channels with minimal debris can deploy a full bench, where the entire channel is enclosed. Whereas drainages that carry significant debris often maintain a half bench to give access for occasional cleaning with the upper half of the pipe open.

According to the National Precast Concrete Association (NPCA), the design criteria for a manhole invert channel are:

- There should be at least a 1.2-inch drop between the inlet invert and output invert with a smooth transition.

- The slope of the invert bench should range between 0.5 inches per foot and 1.5 inches per foot.

- Also, the depth from the bench to the invert level should be a minimum of one-half of the channel pipe diameter. Or in the case where there are multiple channels, the depth should be at least one-half of the largest pipe diameter.