A 3-inch sewer pipe slope should be between 3/16″ and 5/16″ per foot. In this article, we will review how to determine the slope of a 3″ sewer pipe, a 3″ sewer pipe dimensions, and whether a 3″ sewer pipe is possible to reline.

Determining the Slope of a 3″ Sewer Pipe

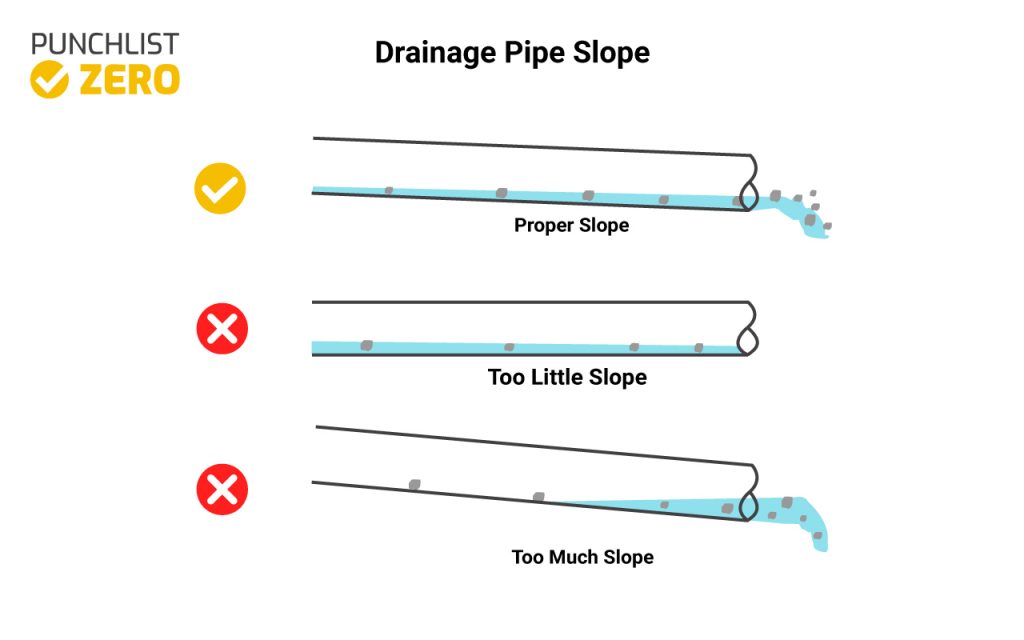

Gravity drainage and sewer pipes need the proper slope for liquids to flow quickly. The proper slope moves sediments away without clogging. Waste cannot move through an excessively flat pipe. Steep pipelines lose the ability to wash out sediment properly as the liquid flows too quickly.

As such, pipe slope should be kept between 3/16″ and 5/16″ drop per foot. As such, engineers can expect around a drop of 1″ every 4 feet. Rare cases allow for 1/8″ per foot, but generally a steeper slope (with a max of 5/16″ per foot) is recommended.

To check the slope of an existing sewer line, one may do the following:

- Put a 4′ level on the pipe.

- Raise the end of the level until the bubble is in the middle.

- Measure the distance from the bottom of the level to the top of the sewer line.

- Divide the measurement by 4 to achieve slope per foot.

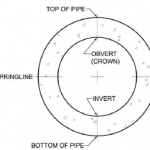

3″ Pipe Dimensions

The 3″ measurement of the pipe notes the nominal diameter. In actuality, diameter measurement varies based on wall thickness. Below are 3″ pipe wall thicknesses based on schedule.

| 5 & 5S | 10 & 10S | 40 & 40S | 80S & XH | 160 | XXH |

| 0.083″ | 0.12″ | 0.216″ | 0.3″ | 0.437″ | 0.6″ |

Most sewer pipe is not pressure retaining and commonly uses SDR pipe.

| Size | 5&5S | 10&10S | 40&40S | 80S&XH | 160 | XXH |

| 1 | .065 | .109 | .133 | .179 | .250 | .358 |

| 2 | .065 | .109 | .154 | .218 | .343 | .436 |

| 3 | .083 | .120 | .216 | .30 | .437 | .6 |

| 4 | .083 | .120 | .237 | .337 | .531 | .674 |

| 5 | .109 | .134 | .258 | .375 | .625 | .750 |

| 6 | .109 | .134 | .280 | .432 | .718 | .864 |

| 7 | – | – | .301 | .500 | – | .875 |

| 8 | .109 | .148 | .322 | .500 | .906 | .885 |

| 9 | – | – | .342 | .500 | – | – |

| 10 | .134 | .165 | .365 | .500 | 1.125 | – |

Calculating pipe size is a common component of flow rate design. Some engineers may reduce the pipe size and increase the velocity to reduce capital costs. Conversely, due to erosion and potential surge pressures, higher speeds might shorten the lifespan of metallic pipes. Reducing the amount of head lost throughout the system maximizes flow rate.

Quicker fluid means more friction loss, putting more pressure on pumps and with improper design, even impose a deadhead pump scenario. Larger pumps may need to be specified, resulting in wasteful spending and more energy draw during operation.

Pipe sizing should always balance cost with efficiency and dependability and ensure conformance to client requirements and industry specifications.

3″ Sewer Pipe Relining

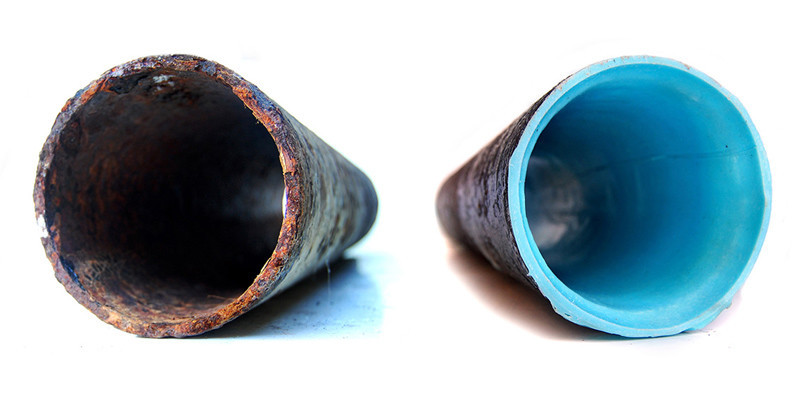

Is pipe relining applicable to 3-inch sewer pipe? Yes, pipe relining can apply to sewer lines and water lines, and compared to standard pipe repair, which necessitates total evacuation, it may provide a good alternative.

Pipe relining fixes cracked or broken pipes from the inside without digging up new ground. It entails inserting a brand-new, durable line inside the broken one to improve flow and seal off cracks. The relined part perfectly seals against the remainder of the pipe system, halting leaks and averting further breakdown.

The following benefits of pipe relining over conventional subsurface plumbing services:

- Little disruption to the utilities.

- Reestablishing service connections from above ground.

- Avoidance of costly evacuation.

- A new pipe’s smooth interior may improve water flow.