Concrete haunching involves using concrete to provide structural support whenever there is no restraint such as a wall or curb. In this article, you will learn the purpose of concrete haunching, the basic steps of the process, and haunching for a pipe.

Purpose of Concrete Haunching

Concrete haunching sees deployment in several scenarios. Generally, it serves to provide support to a structure in the absence of restraint such as a wall. For example, it is common practice to haunch over a drain, so that there is no damage if excavating around it in the future. But, in some scenarios such as in beam-column joints, it provides an economic method of transferring moment into the column. Albeit its use in this application is limited to joints that experience low levels of moment. If the moment on such joints is high, then steel haunches rather than concrete are ideal.

Process of Concrete Haunching

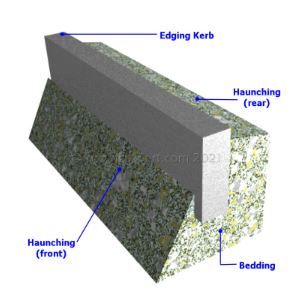

The process of concrete haunching varies according to application. So, reviewing an example is the best way of outlining the haunching procedure. For instance, haunching is essential in securing the perimeter of a paved area, especially in the absence of a wall or curbing. Sometimes, even when using curbs, haunching provides additional edge restraint as the figure below shows.

The haunching process can be simplified into three basic steps.

Laying Bedding Material

After setting up the paved area, lay out the bedding concrete around the perimeter. Typically, the bedding depth should be about 100mm to 150mm thick prior to compacting, depending on the paving blocks height. An adequate amount of sand should be dug out of the foundation to accommodate the bedding thickness, and still give a smooth paving profile. One important consideration during concrete haunching is the mix. Although it varies from one application to the other, 1 part cement to 3 parts sand provide a typical mortar mix.

Laying the Blocks or Curbs

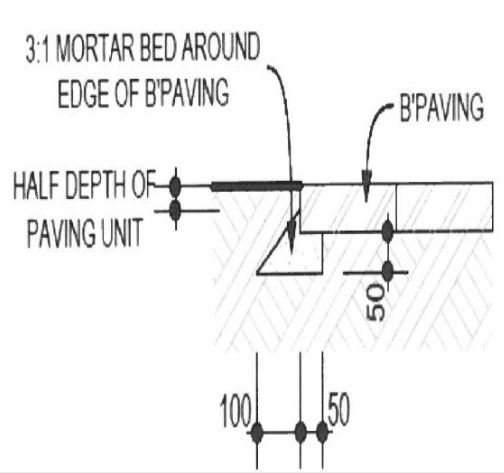

When the bedding is set, lay the edge blocks or curbs on it. Moreover, the bedding material should cover at least half the height of the blocks/curbs. Also, it should have a depth of 50mm minimum under, as the diagram below shows.

To ensure a smooth finish, use a rubber mallet to tap on the paving and assess its alignment with a plumb line.

Haunching

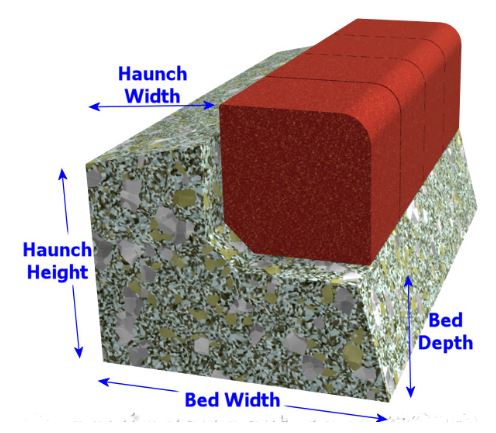

The conclusion of the haunching process is the laying and alignment of the paving. Generally, the specifications of the haunch varies according to the size of the bedding area. It also depends on the dimensions of the curbs/blocks, and the anticipated loading. For example, the width of the haunch should be at least the same as the edge blocks. By convention, it should be 3″ minimum for residential footpaths, 4″ for driveways, and up to 6″ for highways.

Also, the strength of the concrete can be changed by compacting it more or altering the mix to suit the loads. In any case, it is necessary to consider all the variables and follow the specifications when concrete haunching. The key dimensions within the specifications include the bed width and depth, as well as the haunch width and height, as the figure below shows.

Haunching for Pipe

Concrete haunching also serves to support pipes in a variety of scenarios.

Concrete Haunching against Pipe Buckling

Some pipes, such as those transporting oil and gas, are subject to high levels of temperature and pressure. As a result, the pipe may experience buckling, depending on its slenderness and stress levels. When this occurs, there are several issues of concern.

First, the buckle becomes a point of stress concentration where further buckling occurs and results in eventual pipeline failure. Another downside is that the pipeline will crawl, thus shifting position in a manner that negatively affects adjoining equipment. This is a possibility when the installation is in an area with an uneven profile, and the sideways movement due to buckling causes it to fall down a slope. Because of these dangers, it is necessary to dig a trench and bury the pipeline to prevent or limit the pipeline buckling. However, if the soil properties are not sufficient to resist the motion, then, concrete haunching can restrict its movement within limits.

Concrete Haunching for Underground Pipes

In residential and commercial areas, they are often underground pipes that carry sewage, water, and even electrical lines. Due to site development, these buried pipes are at risk of intrusion during excavation. So, concrete haunching provides resistance against unintentional access to these pipes whenever construction activities occur around them.