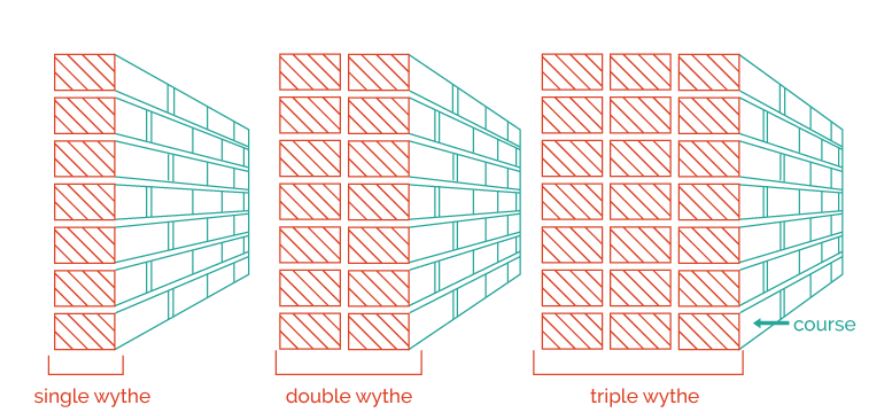

A wythe brick wall refers to a vertical section made from a single line of masonry units. In other words, it is simply a wall that is one unit thick. Although it is possible to use concrete blocks to make a wythe wall, using bricks is popular in temperate regions. In this article, we review the history of the wythe brick wall and the various types alongw with their design considerations.

History

Using bricks in masonry is a practice from thousands of years ago as structures such as the Egyptian pyramids and the Roman colosseum reveal. In the earlier years, the formation of bricks involved combining clay or mud with straw. Then the mixture was placed under the sun to dry, completing the baking process.

Over time, specific demands required cutting the mixture into different shapes. A new level of construction sophistication came around 3,500 B.C. with the invention of kilns for baking bricks. This enabled brick manufacturing all-year round, which was hitherto limited to summer months. Also, with the development of mobile kilns by the Roman empire, bricks became widely adopted in the construction of structures globally.

Initially, a brick wall was solid and made of only a single wythe. But with leakage issues becoming predominant, multi-wythe walls became popular. These walls have a void space between each layer, providing an exit point for moisture that penetrates the external layer.

After the development of multi-wythe walls, came the manufacturing of bricks with voids in them, which is widely in use currently. The introduction of brickmaking into British colonies in North America ocurred during the 17th century. Since then, there have been notable advancements including:

- The invention of the steam-powered brickmaking machine in 1852.

- Transition to more environmentally friendly methods of brick production in the 20th and 21st centuries.

Types of Wythe Brick Wall

This section reviews the features of a wythe brick wall, ranging from the single wythe to the multi-wythe versions.

Single

From the onset of brick masonry, the single wythe brick wall has been fundamental to construction. Although the bricks have evolved from solid to hollow, this type enjoys adoption in a wide variety of structures.

When a single wythe is in use, it means a single layer of brick serves both as the building’s external skin, and interfaces with the users inside. Inherent properties such as high strength, low weight, fire resistance, and good aesthetics, enable it to perform both functions. Because the bricks are hollow, the wall can withstand some level of precipitation.

It offers a cheaper solution to using wood or multi-wythe wall. Additionally, flashing and the installation of weep holes make the brick wall moisture-proof. In addition, the type of bricks used in this system is much thicker than in the multi-wythe system, making the wall more robust.

Multi-wythe Brick Wall

A multi-wythe system uses several layers of bricks to form a wall, with a cavity between each layer. Although there is no limit on the layers, modern designs keep it to a maximum of two layers. Most buildings with three or more layers are likely old designs, especially those built using solid blocks.

Generally, this type of wall is more expensive than the single wythe because more amount of material is in use. However, its deployment ensures greater flexibility in moisture control, better insulation, an increase in fire resistance rating, as well as improvement in sound transmission class. There are two ways of using multi-wythe brick wall system, which are as a composite wall or a non-composite wall.

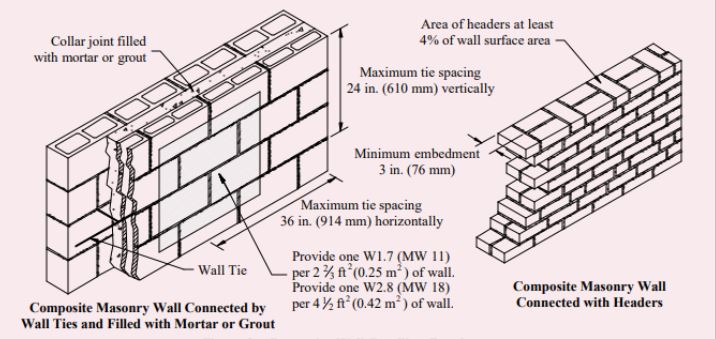

Composite Brick Wall

In this method, the wythes act together as a single unit in resisting loads on the wall. To achieve this, a mortar or grout-filled collar joint connects the wythes and ensures adequate load transfer between them. Another method of connecting wythes is the use of masonry headers, but this is no longer recommended due to some issues.

First, headers are not ductile, so does not accommodate differential movement adequately. As a result, this movement can shear the headers, thereby eliminating the composite action. Moreover, headers make the wall susceptible to moisture penetration. In any case, if headers are used, they must be uniformly spaced and have a total cross-sectional area above 4% of the total wall surface area. In addition, their embedment into each wythe should be a minimum of 3 inches.

Design Consideration for Composite Walls

When constructing composite walls, it is important to follow building code requirements for bonding the wythes and allowable shear stresses for the collar joint. Also, the use of dissimilar materials is discouraged because it does not allow differential movement between wythes.

In addition, the code specifies the design loads to be the axial load from the floor slabs, or the weight of the roof. To support this load, horizontal or vertical reinforcements should be at the vertical joint between wythes. These reinforcements could also be in any of the brick layers. Although the thickness of the joint is not limited by the code, the type of reinforcement in use, and the modular layout govern this parameter.

Another design consideration is the location of insulation, vapor retarders, and fire-rated control joints. Insulation and vapor retarders should never be put in the joint between the wythes. Rather, they should be on the exterior wall, or in the cores of the inner wythe. The fire-rated control joints should extend through both wythes at the same location.

Non-composite Brick Wall

A non-composite brick wall connects adjacent wythes only with a metal tie-in. Moreover, the design of each wythe is to individually resist loads on it. Loads acting parallel to the plane of the wall encounter resistance only from the wythe on which it acts. Transverse loads such as those from wind or fluid, distribute to each wythe according to its relative stiffness.

Design Considerations for Non-Composite Walls

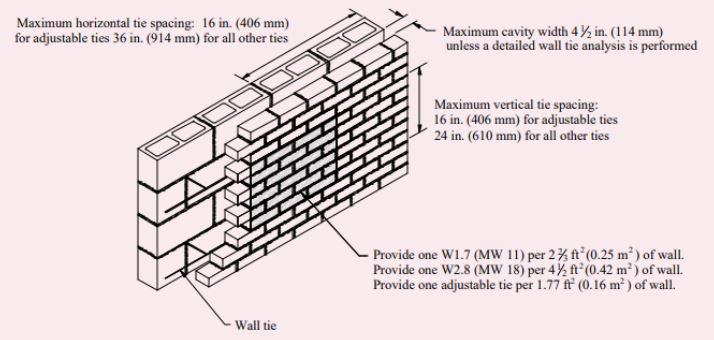

Building code specifications for non-composite walls include:

- The wythe closest to the center span of the supported member carries any imposed vertical load. The distribution of bending loads is according to the stiffness of the wythe.

- Without a detailed wall tie analysis, the cavity width should not exceed 4½ inches.

- Collar joints should not contain headers, mortar, or grout.

- Avoid the use of truss-type joint reinforcement as it restricts the differential in-plane movements of the adjacent wythes. Rather, use the tab-type or ladder-type joint reinforcement.