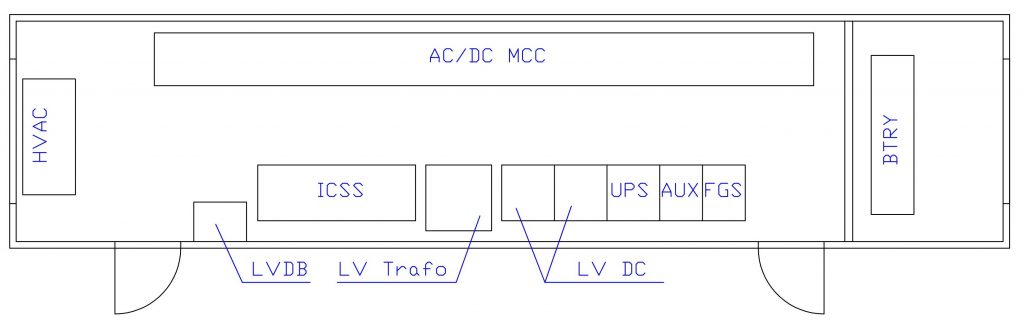

A battery room provides a suitable storage location for keeping batteries protected and isolated. These batteries may serve as a backup energy source or part of an uninterrupted power system. Battery rooms may be standalone but are also frequently found in e-houses.

In this article, we review the purpose of a battery room, hydrogen emissions, battery room requirements, and industry regulations.

Purpose of a Battery Room

When serving as a backup, the purpose is to minimize the harmful effects of power-related issues such as surges and outages. Once any of these occur, the batteries will kick on instantaneously to power the machines. Generally, this is only for a short period to enable a controlled shutdown, or until power is restored from the main source.

Whereas, when serving as an uninterrupted power supply (UPS), batteries provide a continuous feed of filtered power to the machines. The power source charges the batteries when on standby, and they deliver DC power to electronics when necessary. While the UPS device takes DC power from the batteries and supplies clean AC power to devices. The UPS offers better protection against flickering power, brownouts, and surges. As a result, engineers prefer specifying batteries to powering sensitive and mission-critical devices such as those in data centers.

Also, industry regulations mandate the use of a battery room from 50 kW of direct current power for recharging forklift trucks and cart batteries. In this application, there is frequent human interfacing with the batteries as personnel come in and out when changing batteries. This highlights the need for measures to ensure the safety of both equipment and personnel.

Hydrogen Emissions in a Battery Room

When recharging batteries, particularly lead-acid varieties, chemical reactions occur, leading to hydrogen emissions. The hydrogen generation rate depends on factors such as the battery power, charger power, and type of equipment. If the hydrogen attains concentration levels between 4.1% and 74.8%, it easily combines with oxygen in the air, forming an explosive gas. As a result, measures should always be in place to monitor the hydrogen content in a battery room and prevent its buildup.

Battery Room Requirements

Although there are several requirements governing the use of a battery room, most stem from the dangers of hydrogen emissions. The following sections summarize industry regulations bordering ventilation, lighting, and other requirements.

Ventilation Requirements

The buildup of hydrogen gas constitutes the most danger in a battery room. To avoid this, the room requires ventilation, which can be natural or mechanical. Whatever the ventilation option, adequate exchange of air must occur to remove the gas produced from the batteries. For natural ventilation, openings are ideally opposite each other to deliver cross-ventilation. But if not possible, they can be on the same side of the wall at least 2m apart. The air should enter close to the floor and exit higher at the opposite side. The size of the ventilation openings depends on the air exchange rate demand, which varies with the kind of batteries. This is more of an issue only with natural ventilation.

For mechanical ventilation, the size of openings is less of an issue because the device can be configured to satisfy air exchange rate demands. Regulations may require mechanical ventilation to keep the hydrogen concentration in the battery room at 1% or below. Also, it is mandatory to have an automatic charging shutdown if the ventilator develops a fault. In addition, a hydrogen measurement tool that can activate the ventilation and stop the battery charging should be present.

Lighting and HVAC Requirements

- Due to the presence of hydrogen gas, it is necessary to eliminate every source of ignition within the battery room. So, it is ideal to use explosion-proof lighting.

- Because hydrogen gas is lighter than air, it tends to accumulate at the roof of the room. Hence, the position of all lighting must be away from the highest point in the room.

- All switches for lighting and timers of motors must be outside the room.

- Batteries operate optimally at 20°C, so the HVAC should keep the room within that temperature range. Despite the air-conditioning, there must be regular ventilation of air alongside close monitoring of the hydrogen concentration level.

Location Requirements

- The battery room should be as close to the load as practicable to minimize the cost and exposure of the distribution system.

- The location of the room should be such that batteries are away from flooding, vibrations, and heat from the operating area. Also, room location should allow easy access for lifting equipment to aid in installation and maintenance activities.

Architectural and Layout Requirements

- Floors should be acid-resistant or resistant to damage from any electrolyte spillage.

- The dimensions of the battery racks should be orderly to ensure easy inspection, testing, and maintenance operations.

- Battery room layout should allow for easy access and movement of batteries and lifting equipment.

- There should be provision of locks that restrict access to only qualified persons.

Battery Room Signage

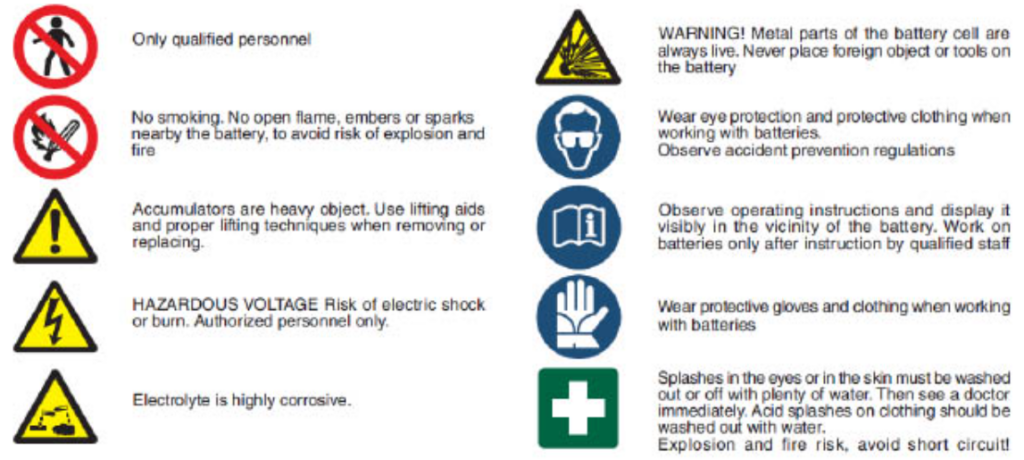

Appropriate signage should be in place in a battery room with examples in the figure below.

Battery Room Equipment

- The use of PPE is necessary during all operations in a battery room. For example, goggles/face shields, rubber gloves, and protective aprons.

- Class C fire extinguisher.

- Facilities for eye-washing should be within 3m of the work area.

- Hydrogen gas monitors, carbon monoxide detectors, and fire/smoke detectors. If the battery room experiences high vehicular traffic, then forklift fleet management system should be in place.

Industry Codes

The battery requirements in the previous sections are based on the following codes:

- National Fire Protection Agency (NFPA): Codes from the NFPA that influence battery rooms are NFPA 70 – National Electric Code and NFPA 2 – Hydrogen Technologies Code. Others include NFPA 1, Chapter 52 – Stationary Storage Battery Systems and NFPA 505 – Fire Safety Standard for Powered Industrial Trucks.

- International Fire Code (IFC): This includes IFC 608.5, 608.6, 608.7, and 608.9 that cover Spill Control and Neutralization, Ventilation, Signage, and Smoke Detection respectively.

- Occupational Safety & Health Administration (OSHA): OSHA has several codes that are important to the operation of a battery room such as the 1910.132 and 1910.133 for PPE. OSHA 1926.441 covers batteries and battery charging, while OSHA 1910.305 covers electrical wiring and components such as mechanical ventilators.

Other important codes include IEC 62485 and IEEE 484, with both covering the installation design and installation of stationary batteries.