Soil boring refers to the drilling of the soil for the exploration of soil samples at various depths. Depending on the method in use, the process yields both disturbed and undisturbed soil samples, which undergo examination in line with the set purpose. In this article, you will learn about the methods of soil boring, the soil boring test, a soil boring log, and soil boring vs test pit uses.

Methods of Soil Boring

There are several methods of soil boring available depending on the purpose of the exploration and the resources available for the project. Before choosing a method, the geotechnical engineer should consider the soil type, the desirable type of soil samples, and the availability of the boring technique facility.

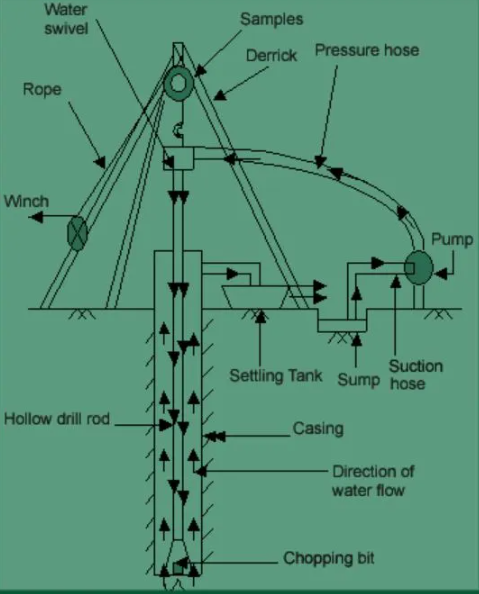

Wash Boring

This is a popular method of soil boring because it does not require as much equipment as most others. Hence, wash boring provides portability at a low cost. After forming an open hole on the topsoil, the chopping and twisting action of a light bit advances the hole to the desired depth. Then, a water jet passes through rods in the hole to carry out the cutting.

As a result, this method produces disturbed samples which makes it unsuitable for very soft soil, fine to medium grain non-cohesive soil, and cemented soil.

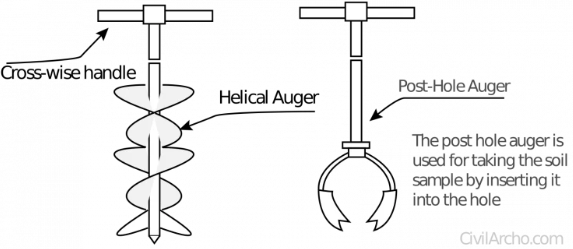

Auger Boring

This is another inexpensive and flexible method that serves for both small and large bores. It is a trenchless application where both the casing and helical augers simultaneously drive into the earth surface. The augers remove the excavation, while the casing reduces the likelihood of soil settlement. Because it is a dry method, it is not suitable for very hard soils or cemented soils, and very soft soils, to avoid flow into the hole. But it is ideal for soft to stiff cohesive soils.

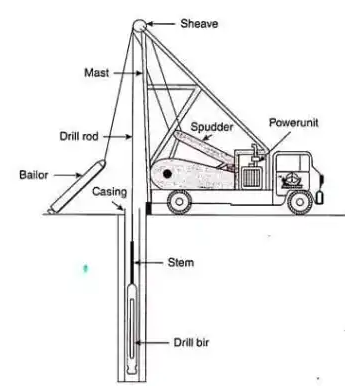

Percussion Drilling

When wash and auger boring methods cannot penetrate hard soils or soft rock, percussion drilling provides a strong solution. In this method, drilling occurs by the alternative lifting and dropping of a heavy drill bit via a cable. If penetrating through clay, addition of sand helps the cutting action of the drill bit. For coarse non-cohesive soils, addition of clay increases the carrying capacity of the slurry.

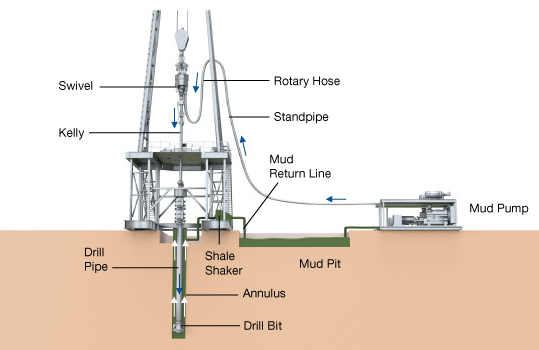

Rotary Drilling

If a soil constitutes highly resistant strata such as rocks, then rotary drilling is the most suitable approach to use. Also, it can serve for other soil types. In this method, a pump circulates water or drilling mud from a pit to remove the soil fragments cut by the drill bit. In addition to removing soil fragments, the drilling fluid helps to stabilize the borehole. Generally, this method is suitable for boring hole diameters of 4 inches (100 mm) and above. Because it becomes uneconomical if used for smaller dimensions than this.

Soil Boring Test

A soil boring test is a technique that investigates and determines the condition and composition of the soil at a site. Moreover, this process involves taking several shallow cores out of the sediment, then carrying out a variety of tests to determine soil characteristics. A soil boring test is site-specific and is due to several reasons.

Purpose of Soil Boring Tests

Construction, mineral exploration, and environmental safety provide three common reasons for conducting soil boring tests on a site:

- Construction: The performance of any structure heavily relies on the design and construction of its foundation. As a result, it is necessary to consider soil-structure interaction at the onset of every construction project. During these tests, the geotechnical engineer determines details of the subsurface soil profile and other static characteristics. Then, this information serves as the basis for designing a foundation suitable for the type of structure that is to be on site.

- Mineral Exploration: Carrying out soil boring tests reveals a lot about the soil composition of a site, including its potential to contain mineral resources. Thus, these tests are integral activities in the exploration of oil and gas, as well as other mineral resources.

- Environmental Safety: Soil boring tests may assess the condition of the soil in such sites in the event of a spillage. In addition, even if there is no spillage, information from these tests enables regulatory bodies to ascertain compliance with industrial waste disposal regulations. Generally, checking soil samples between 0 ft to 3 ft from the surface reveals potential contamination that may affect human, animal, and plant life. Checking depths between 3 ft to 15 ft shows contamination that can affect utility lines.

Soil Boring Log

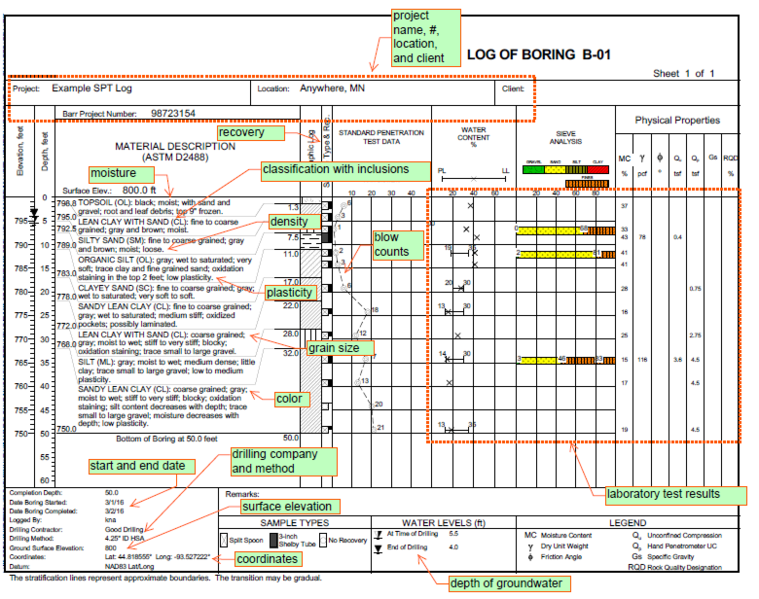

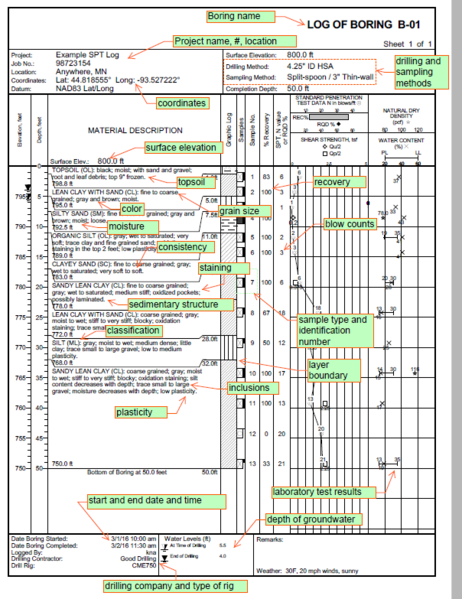

The soil boring log is the basic record of most geotechnical explorations. Moreover, it contains records that describe exploration procedures and subsurface conditions experienced during drilling, sampling, and coring processes. The basic contents of the log are usually divided into several sections.

Project Information

The log should contain basic information about the project such as its name/number, location, drilling contractor, drilling equipment, and the boring methods. Additionally, the weather information, personnel carrying out each task, as well as date and time of work should all be covered in detail. Typically, this should be on the first page/sheet of the soil boring log.

Soil Boring Location and Elevation

The exact coordinates of boring, alongside its elevation with respect to a datum, are important information that is always available in a soil boring log. Also, it should contain records of any deviation in the boring location.

Stratigraphy Identification

Stratigraphy identification summarizes the subsurface conditions on the basis of observation of the soil samples and drill cuttings. Also, comments from the operator about the performance of the drill rig help in describing the strata such as existing fill, topsoil, and pavement sections. The presence and thickness of these strata should be specified. These attributes may have a significant impact on the conclusions and recommendations of geotechnical studies.

Sample Information

The soil boring log should show information about the samples such as sample type, depth, time and date of recovery, and sampler types. Moreover, standard notations, graphical or abbreviations systems should indicate all these details. Also, every sample attempt should have a sequential number for proper identification.

Soil Description and Classification

At a minimum, this section should include soil type, particle distribution, color description, water content condition, and apparent consistency or density. In addition, other details such as inclusions, plasticity, and texture of the soil are necessary to provide an adequate description. All nomenclature, symbols, and categorization should be in line with industry standards such as AASHTO M 145, ASTM D-2487, and ASTM D-2488.

Generally, the presentation of soil boring logs is either horizontal or vertical, as the samples below show.

Soil Boring vs Test Pit

Generally, soil boring and test pits serve similar purposes of uncovering and enabling the investigation of the subsurface conditions at a site. However, there are some differences in their uses as the table below highlights.

| Soil Boring | Test Pit |

| This is carried out using more complex drilling equipment. | Test pits are dug either manually with backhoe equipment or with an excavator. |

| Generally, a more expensive and complex procedure. | Because less sophisticated machinery is used, the process incurs less cost. |

| Soil boring is done to varying depths. But, typically deep, in excess of 15 ft. | These are shallow, and normally within the range of 3 to 15 ft. |

| The sizes of the holes are limited, allowing for only soil samples to be taken out. | The holes are much larger. Thus, allows soil scientists and other professionals to physically examine the soil en masse. |

| Because this accesses greater depths, more complex operations such as monitoring seasonal groundwater levels and exploring mineral resources, can be done. | Shallow depths limits operations to carrying out tests for shallow foundation construction and evaluation for soil contamination. |