IFC drawings, also called Issued For Construction drawings, are approved drawings from which a product can be built. In this article, you will learn the meaning of IFC drawings, compare IFC drawings vs. other types of drawings, and learn the IFC drawing revision process.

Meaning of IFC Drawings

IFC provides the abbreviation for “Issued for Construction”. These drawings typically have gone through an approval cycle. The approval cycle may be internal only, but often involves one or several customers. The IFC drawings usually include general drawings such as a general arrangement and P&ID drawings as well as shop drawings.

Taken collectively, the drawings should be able to communicate all requirements for taking raw materials and fabricating a finished product. After completion, IFC drawings release to the fabrication floor or field via a controlled release process. This process usually involves a release from the Document Control and/or Quality Control department.

IFC Drawings vs. Other Types of Drawings

Drawings cycle through various phases, from tender, to IFA, and IFC. As a project moves onward, the amount of detail increases. Thus, an IFC package includes more drawings than a tender package. Its important to understand that tender, IFA, and IFC drawings are often the same drawings throughout. The tender, IFA, and IFC designation denote how the drawings/drawing packages are being used.

IFC vs. Tender Drawings

Tender drawings, completed during a proposal phase, provide the first set of drawings. They are the engineer’s vision for the project, which is utilized to estimate and price the building’s cost. These drawings provide a wealth of information about the construction so that contractors bidding on the job may fully comprehend the project.

Tender drawings may include PFDs, P&IDs, and G/As. PFDs and P&IDs usually track close to the final expected drawings. However, G/As take on a more pliable and incomplete form.

Equipment providers and fabricators generate a tender package from the tender drawings. A tender package typically consists of a complete set of pictures and a specification paper for the entire project, outlining materials, craftsmanship, and needed standards.

IFC Drawings vs. IFA

Issued for Approval (IFA) means that the document or drawing gives to the client or delegated authorized person/organization to review and approve their use for further developments or activities. Some examples include project critical documents such as the P&ID and G/A.

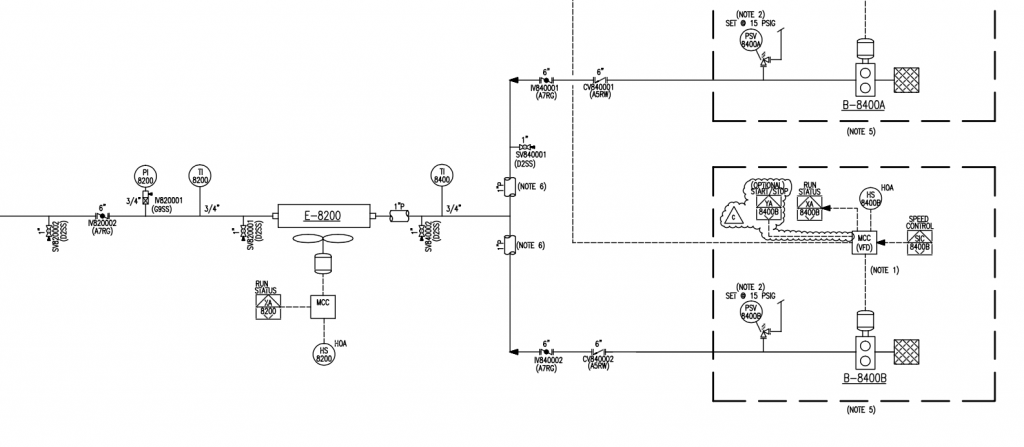

P&ID

In the process industry, a piping and instrumentation diagram depicts the piping and process equipment and the instrumentation and control devices. This important document provides overall sizing guidance and operating condition on all instrumentation, piping, vessel, and equipment in the system.

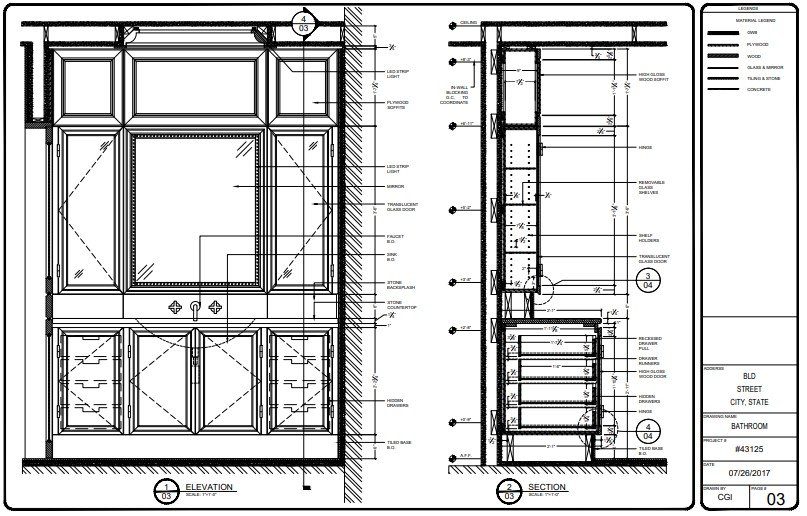

General Arrangement

General arrangement drawings depict the location of the equipment – both from an elevation and plot plan viewpoint.

IFC vs. Shop Drawings

The IFC designation simply notes the subject document is ready for construction. As such, IFC drawings include all drawings in the overall part or assembly package. By contrast, a shop drawing exists only to provide constructability detail. Shop drawings, such as a pipe spool drawing, typically do not get transmitted to the end-user.

Thus, every shop drawing is an IFC drawing, but every IFC drawing is not a shop drawing.

IFC Drawings vs. As-Built Drawings

As-built drawings provide a completed drawing of a product, assembly, building, or land area. They provide the exact dimensions, shape, and position of all aspects of the work accomplished under the contract and reflect all changes made to the requirements and working drawings during the building process.

The final as-built drawings include details below, as well as every other change made during the construction phase of a project:

- Modifications

- Field changes

- Shop drawing changes

- Design changes

- Extra works

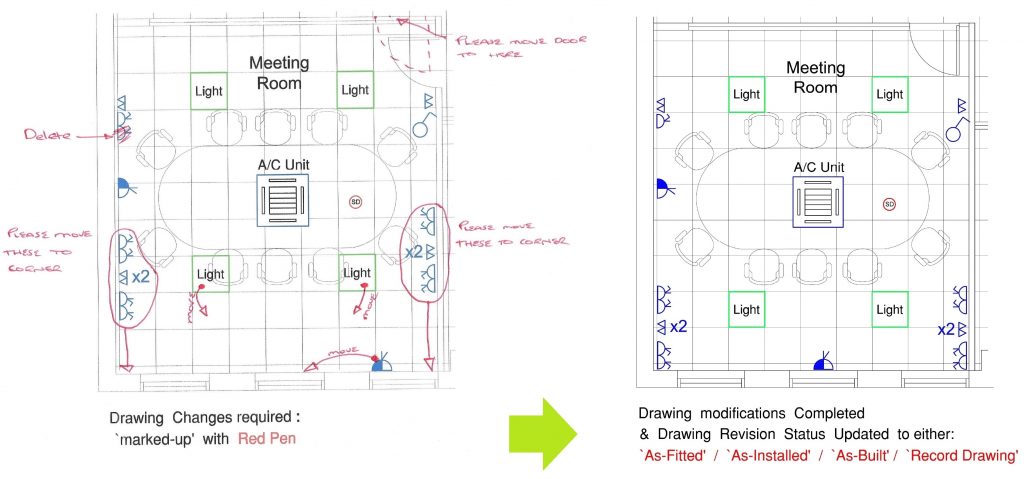

As-builts originate from IFC drawings. Typically, an engineer or technician provides redlines on IFC drawings to indicate changes in the build that occurred during construction. Then, engineers receive those marked-up IFC drawings and generate as-builts from the package.

Most frequently, as-built drawings are simply rolled to the latest numeric revision and denoted “As Built” in the comment block. Some firms prefer to notate the latest revision as “AB”.

Drawing Revision

Engineers frequently have to revise construction prints based on shop input, usually stemming from an engineering error. Thus, for small issues, engineers usually elect to provide a redline directly on the print. The redline process generally is limited to changes that do not affect the form, fit, or function of the manufactured item.

Issues that affect form, fit, or function typically require electronic revision and reissue to the shop. Additionally, if communicating the change via redline alone is too difficult from a spacing and legibility perspective, an engineer may wish to revise the drawing electronically.