The material property known as emissivity describes a material’s propensity to radiate energy. Emissivity measurements, sometimes referred to as an e-value, range from 0 to 1. A measurement of 0 indicates a shiny mirror whereas a measurement of 1 represents a blackbody. In this article, you’ll learn the importance of emissivity in material selection, its calculation process, and how to modify emissivity to meet project requirements.

Emissivity Material Selection

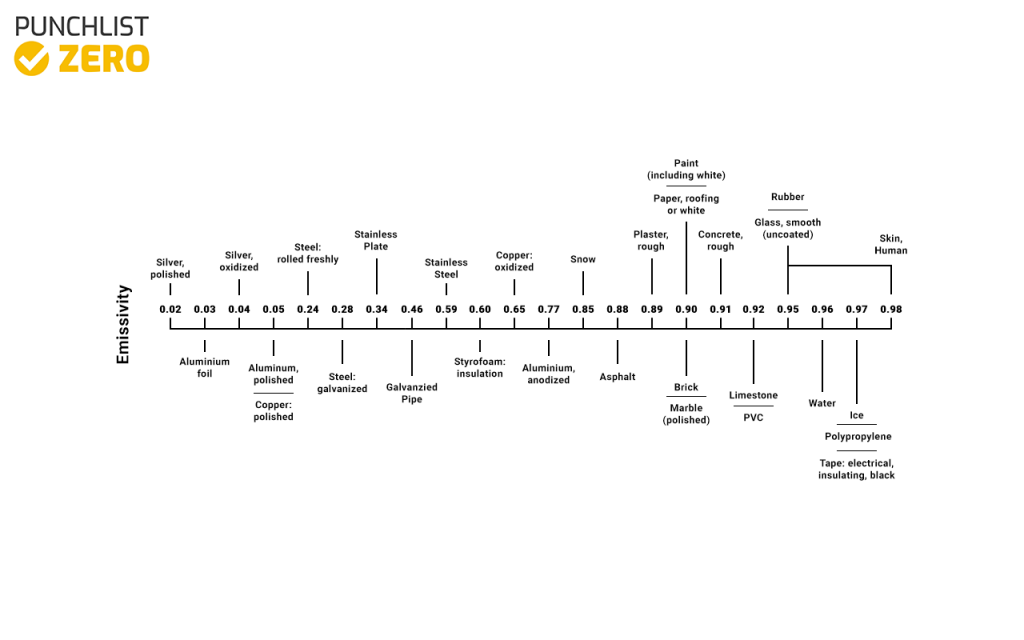

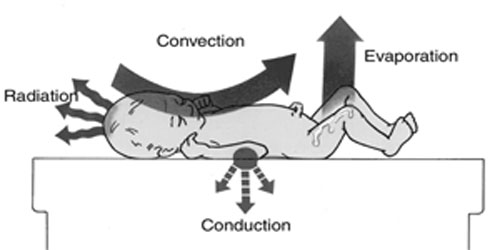

Heat transfers via one of several means: conduction, convection, or radiation, and in the human body, perspiration. The heat loss rate via radiation originates from two major factors: the temperature gradient between the emitting body and the ambient temperature, and the objects’ ability to emit and absorb radiation. E-values are usually influenced by color. Black increases the e-value and white decreases its value. Surface finish also plays a major role in an object’s ability to absorb or reflect radiation. Shiny, mirror-like finishes have low e-values and reflect radiation while rough objects are more likely to absorb and emit radiation.

Engineers use this understanding of emissivity and associated radiative heat loss in product design. PCB manufacturing and design provides a common example of designing heat loss. PCB components includes an expected heat discharge. Product designers manipulate a PCB components’ ability to emit heat by adding specialized coatings and using dark materials. The specialized coating allows for a set amount of heat to discharge, thus allowing for an optimized overall system cooling design.

In building design, low e-values are desirous as a low e value minimizes heat loss to the surrounding air. The reflectivity of glass produces an e value near 0. Additionally, glass and roofs may be given a special coating to further reduce radiant heat losses.

Methods to Estimate Emissivity

Estimating the emissivity of a material surface proves difficult based on the varying conditions that make up the measurement. The e-value of an object depends on surface finish, temperature, and color. The chart below provides estimated value across a broad range of materials.

The difficulty of providing a standard emissivity measurement is best exemplified by the human skin. Skin provides energy exchange between a human and its surrounding environment. Heat loss occurs via conduction, convection, and radiation. Each area of a human body, depending on perspiration, hair, and skin roughness provides a different emissivity value.

As a result, conservative estimations of emissivity suffice in most situations. Engineers employ specialized instruments when an object requires an empirical measurement. First, a standard temperature tool gauge such as an RTD provides a temperature measurement. Then a specialized instrument provides a temperature read-out. This specialized instrument allows for the adjustment of an emissivity value until the tool’s temperature read-out matches the originally measured temperature.

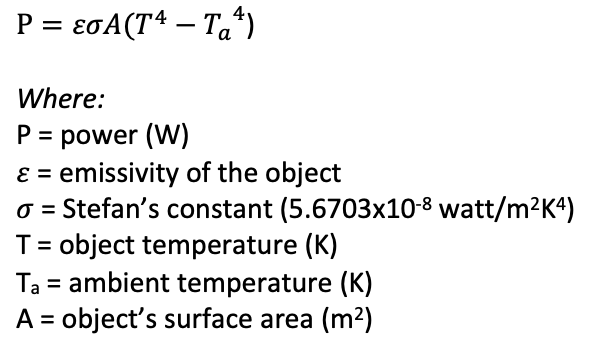

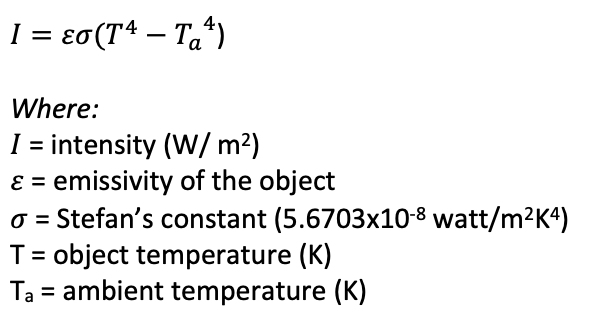

To calculate the heat transfer that occurs as a result of emissivity and radiant heat loss, Stefan-Boltzmann’s formula is employed.

Theoretical forms of the Stefan-Boltzmann equation may eliminate the ambient temperature measurement. However, real-world applications always necessitate the evaluation of surrounding ambient temperature. At times, engineers may need to calculate the amount of power delivered per unit area. In this instance, the object’s area can be removed from the equation and the equation simplifies to:

Modification of Emissivity

Engineers may elect to maximize an object’s emissivity value such as the PCB example, or minimize its value such as in a building’s windows. During testing, an engineer may deploy temporary measures such as a dye-penetrant, stickers, markers, tape, and contact tape. To manipulate emissivity permanently, engineers use solutions such as stick-on labels, tape, marker, rubber, coatings, and paint. Surface finish treatments such as machining and polishing may also be employed.

Labels, Tape, and Markers

These types of surface modifications typically are not thought of as permanent solutions. However, for forgiving environments, labels, tape, and markers may economically provide the needed modifications. Electrical tape provides emissivity of around 0.95 and provides a long-lasting solution. Uses may also specify stickers that provide a known value.

Paint

A paint’s flatness lends more weight to its emissivity value than its color. Flat paints provide higher values than glossy. A two-coat paint system or a single paint with two colors provides adequate coverage to change an object’s emissivity. A flat, two-coat paint system with full coverage delivers a value between 0.9 and 0.95.

Coating

Physical vapor deposition (PVD) coastings deposit layers of material onto a wide range of material types. Deposits typically provide around a few millimeters of thickness. PVD coatings provide uniform coating and emissivity values at a high price point than most painting options. Coatings provide a better option than painting in tough and high temperature environments.

Foil

Foil makes a lot of sense when users desire reflectivity and low emissivity values. Most insulation has a reflective foil that protects against radiant heat. Emissivity measurements of reflective foil range from 0.02 to 0.1. Foil’s values vary depending on corrosion. Thus, particular importance must be placed on the foil’s expected environment and to whether the foil will be protected from corrosion.