Many drivers apply anti-seize to spark plugs. This article explores whether anti-seize on sparkplugs is a good idea and how to remove a stuck spark plug.

Spark Plug

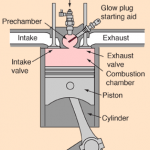

A spark plug is an electronic device that fits into the cylinder head of some internal combustion engines and ignites compressed aerosol gasoline with an electric spark. Spark plugs have an insulated center electrode connected to an ignition coil or magneto circuit on the exterior by a substantially insulated wire. This generates a spark gap within the cylinder with a grounded terminal on the plug’s base.

Function

A spark plug’s job is to produce a spark at precisely the right time to ignite the explosive combination. The plug connects to high voltage generated by an ignition coil or magneto.

A voltage arises between the center and side electrodes as current flows through the coil. No current can flow initially because the fuel and air in the gap are insulators, but as the voltage rises, the structure of the gases between the electrodes begins to change.

The gases become ionized when the voltage surpasses their dielectric strength. The ionized gas transforms into a conductor, allowing current to pass through the gap.

What is Anti-Seize?

To ease disassembly, anti-seize products are applied to bolts, fasteners, flanges, and other clamped interfaces to prevent galling, seizing, corrosion, and lubricating.

Anti-seizes can be pastes, greases, and coatings, and they can be based on a wide range of materials (e.g., copper, nickel) to suit particular systems. Therefore, selecting the correct anti-seize product for the specific design is crucial.

Is It a Good Idea to Apply Anti-seize on Spark Plugs?

Anti-seize shouldn’t be used on all spark plugs. There are actually two types of spark plugs; ones that are not compatible with anti-seize and ones that might be.

If you see a spark plug with a nice chrome-type finish on the threads that’s very silver-like, don’t use anti-seize. Those are already treated to deal with the head, given its aluminum or steel, and they don’t need any anti-seize on the middle.

In fact, if you use anti-seize, you could be damaging the head and the spark plug itself because the addition of anti-seize completely throws off the torque specs. Thus, a technician may think a sparkplug is being tightened to 65-foot pounds, but with anti-seize, the true value could be 20 foot-pounds higher. Thus, the spark plug could snap or damage the threads in the engine head.

Spark plugs with a black oxide finish may take a moderate amount of anti-seize. However, truth be told – today’s spark plugs are generally already plated with anti-seize chemicals. That black oxide finish likely already has anti-seize chemicals or is designed in such a way that additional anti-seize is unnecessary.

The anti-seize benefits are small and the risks are high. Thus, adding lubricant is unnecessary and can be detrimental in almost all cases.

How to Use Anti-seize on Spark Plugs Safely

Ok, so we haven’t convinced you to not use anti-seize. Or maybe you are working on an older model truck with antiquated spark plugs. Whatever the case, understanding two fundamental concepts about anti-seize allows for a safer use.

Anti-Seize Reduces The Friction Coefficient

Anti-seize generally reduces dry torque value by around 20%. If you’re unsure whether a given torque value is dry or wet, assume it is dry torque figures unless it expressly says “wet torque.”

It’s important to point this out because you’ll eventually break the spark plug head if you frequently tighten a wet thread to dry torque values.

Also, keep in mind that anti-seize lubricant makes it much easier to overtighten the spark plug. The pins will be damaged if they are over-torqued, which might cause engine damage.

Use A Tiny Amount Of Anti Seize

Use a tiny amount on the middle area of the threads, leaving the initial plug thread unaffected.

The first thread is closest to the ground and electrode of the spark plug. Anti-seize may cause the spark plug to be short, resulting in engine misfire, spark plug thread damage, combustion gas leaks, and other issues.

A nickel-based anti-seize compound is recommended because it has the best heat resistance.

Never apply anti-seize on rubber seals, engine internals, or any bolt or lug nut that requires a thread compound (such as cylinder head bolts). Anti-seize works similarly to grease, while thread compound like Loctite or Permatex is sticky.

How to Remove Stuck Spark Plug

Modern plugs offer a longer life, which also increases the possibility of a jammed spark plug. To remove a blocked spark plug, proceed cautiously and follow these step-by-step instructions.

Step 1 – Find the exact location of your engine’s spark plugs. Many vehicles have spark plugs in difficult-to-reach spots, such as the bottom or side of the car. In such circumstances, a lift may be required for access.

Step 2 – Pull off the spark plug cap.

Step 3 – Spray penetrating oil down the barrel of the spark plug so the oil creates a good coating around the pin. The penetrating oil assists in loosening any buildup or rust that may cause the spark plug to seize.

Step 4 – Wait for at least 10 to 30 minutes. This allows the oil to penetrate the carbon buildup around the spark plug. The longer you wait, the better. The penetrating oil should soak overnight for extremely difficult to remove plugs.

Step 5 – Give the end of the seized spark plug a gentle tap.

Step 6 – Before attempting to remove the spark plug, turn it slightly tighter. Then spin it counterclockwise to loosen it.

Step 7 – Soak the spark plug with oil again if it is still stuck.

Step 8: Turn on the vehicle’s engine. The heat helps dislodge the muck around the plug, allowing the oil to penetrate further into the thread of the spark plug.

Step 9 – Allow the engine to cool before touching it to avoid a burn injury. Steps 1 through 4 should be repeated until the seized spark plug comes loose.