Ordinate dimensioning refers to measuring elements on a drawing according to their perpendicular distance from a fixed point or “datum”. This is one of the methods of dimensioning in design, which offers several advantages because of its minimal footprint. In this article, you will discover the value of ordinate dimensioning, when to use it, compare ordinate dimensions vs linear dimensions, as well as baseline dimensions.

Value of Ordinate Dimensioning

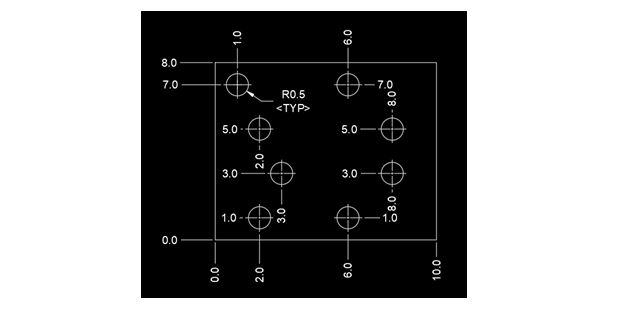

Ordinate dimensioning offers unique features in comparison to other dimensioning methods. Generally, this method is ideal for measuring midpoints, vertices, edges, as well as the centers, minimum, and maximum points of arcs. Because the measurement of each element is with reference to an origin, all elements are automatically grouped to maintain alignment. As a result, the offset between elements is always intact, which helps minimize errors during fabrication. This is advantageous especially when the relative position of elements is key to the functionality of a design.

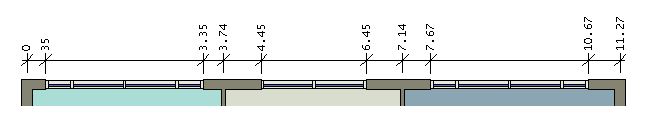

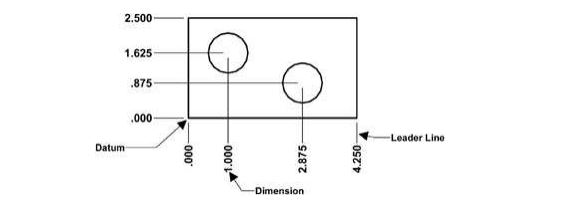

Another importance of ordinate dimensioning is that it minimizes the footprint of dimensions as the figure above shows. Typically, dimensioning involves a lot of elements including the dimension lines, arrow heads, projection lines, and construction lines. However, an ordinate dimension has just a datum with leader lines indicating the position of the elements in the drawing. For drawings that have several elements to dimension, using this method can significantly declutter the design. Thus, making it easier to interpret.

When To Use Ordinate Dimensioning

Selecting the right dimensioning method for a design is key to ensuring accurate interpretation, which minimizes error during fabrication or manufacturing. In certain situations, designers deploy multiple dimensioning styles to clearly communicate measurements. Out of the different dimensioning styles, ordinate dimensions are among those that a popularly used alongside other methods. Some reasons why this method is often in use include:

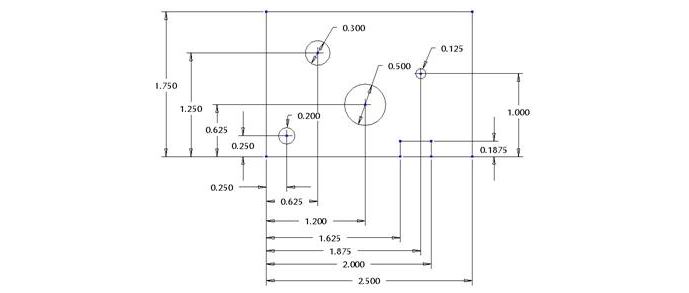

- Ordinate dimensioning is good for designs where there is need to only identify the X and Y coordinates of elements. For example, this dimensioning method clearly describes all measurements of a flat plate with several holes of the same size in the figure below.

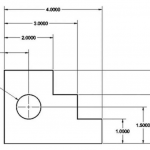

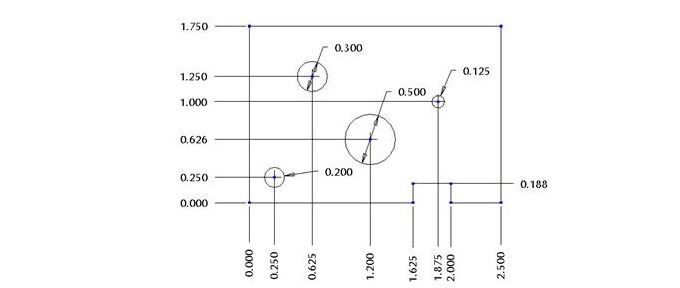

Another good use of ordinate dimensioning is to declutter a drawing. For instance, linear dimensioning is a method that is present in many designs. However, it deploys dimension lines which takes up space like in the figure below.

If ordinate dimensions were to replace the linear dimensions, it would be easier to read as the figure below shows.

However, the use of ordinate dimensions is avoided when using Geometric Dimensioning & Tolerancing (GD&T). Because this helps eliminate the downsides of coordinate tolerancing. GD&T is preferable because of the following reasons:

- Clearer measurement requirements that make it easier to inspect a part.

- Better focus on the part functionality.

- Provides larger tolerance area.

- Also, GD&T provides bonus tolerance when the design of a feature is for maximum material condition.

Ordinate Dimensions vs Linear Dimensions

Linear dimensioning is a method that takes measurement between any two points on a drawing. Moreover, it is largely different from ordinate dimensioning as the following table highlights.

| Ordinate Dimensioning | Linear Dimensioning |

| All measurements are from a datum. So, there is only one reference point in each drawing. | Measurements are from any two points, thereby making it more specific to a feature. |

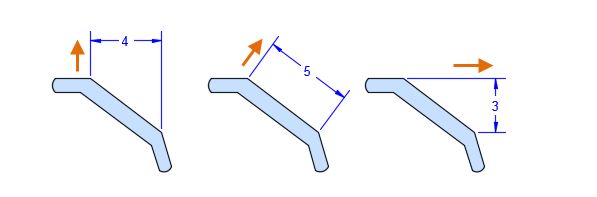

| The direction of measurements are either in the horizontal or vertical direction. Thus, is always perpendicular. | Linear dimensions could be horizontal, vertical, or at an angle aligned to the feature. As a result, it offers more flexibility. |

| Generally, it offers a design with less clutter, which makes it easier to interpret. | Drawings that use linear dimensions could easily become crowded with dimensions if not properly managed. |

| Because all measurements are from a single datum, escalating errors are minimal. | Prone to escalating errors due to multiple reference points. |

| Not suitable for GD&T. | The ideal method for GD&T. |

Ordinate Dimensioning vs Baseline Dimensioning

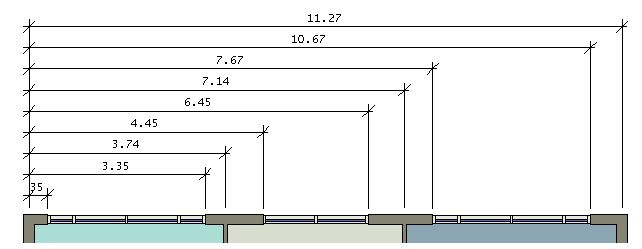

Baseline dimensioning is a method that shares a lot of similarities with ordinate dimensioning. Both methods involve using a single datum for measurements, which minimizes escalating errors. Also, both provide measurements only in the perpendicular directions – either X or Y coordinates. However, the baseline method uses dimension lines to indicate the measurement of elements. Whereas the ordinate method does not. As a result, designs with baseline method appear to have more clutter, occupy more space, and could be difficult to read in some cases. A clear example is in the following design that uses baseline dimensions.

If ordinate dimensions were to replace the baseline dimensions, the figure would be easier to read as the figure below shows.