A lock nut is a nut that resists loosening under vibrations and tension. It is also known as a locking nut, self-locking nut, prevailing torque nut, stiff nut, or elastic stop nut. Adjustable stop nuts and overall torque nuts are the types of nut that deforms elastically to generate a locking action. The first variety, invented in 1931, used fiber instead of nylon.

Vibration and shock can loosen a bolted connection. Therefore, a method of fixing the connection helps keep the bolt-nut combination in place. In this article, you will learn the lock nut purpose, types, sizes, and alternatives.

Purpose

Shock and vibration are two of the most prevalent reasons that a threaded fastener connection loosens. Friction, bolt stretching, and compression of the pieces hold the threads of two sections together. Specialized locking nuts can help avoid loosening of this connection.

When exposed to vibration, lock nuts provide a unique design that reduces the possibility of loosening. Because traditional nuts only have a single-threaded hole, they may break loose from the attached bolt during service. On the other hand, locknuts possess a design that boosts the nut’s resistance to vibrations.

All metal lock nuts, such as stainless steel lock nuts, mild steel, zinc, or brass lock nuts, favor heavy-duty and industrial applications. However, part-nylon or all-plastic lock nuts also apply to many applications, as long as the torque forces they endure are not too high.

Types

Metal and nylon insert locknuts are the most prevalent types. Metal lock nuts are available in a variety of shapes and sizes. Here is a list of the most common varieties of lock nuts, along with illustrations for recognition purposes.

1. Nylon Insert Lock Nuts

When threading the bolt through this type of nut, pressure exerts on the screw and prevents it from coming free or falling off. The nylon insert nut has an inside nylon washer or patch; the non-metal substance makes the nut more temperature and chemical sensitive.

2. Hex Jam Nuts

The jam nut, frequently used in conjunction with another nut, should tighten them up against each other – it is how they work and why they’re called jam nuts. Jam nut can also utilize them in narrow spaces where a full-sized nut would not fit.

3. Stover

The Stover includes a built-in locking mechanism that acts like a locking nut as it is secured. Its self-contained feature causes frictional interference between the threads of the matching components. When tightening a prevailing torque lock nut, there is resistance to rotation during assembly and disassembly. This necessitates wrenching and greater torque than a standard nut.

4. Center Lock Nut

There’s a small mark on the exterior of this nut in the middle position, indicating it’s a two-way nut. As the name implies, this type of nut locks in both directions, so whether being assembled or disassembled, it begins to lock. To restrict the nuts from loosening, both the Stover and the two-way style deform threads. The distinction is that the twisted rope in Stover nuts is at the top, whereas it is in the center of two-way nuts.

5. Serrated Flange Lock Nut

This fastner features an integrated flange and serrates on the rear, and generally applies in applications with metal sheets or other metal components. The serrations keep it from backing off after tightening.

6. Keps K-Lock

K-Locks have movable wings, and it’s a free-rolling washer lock nut. When the attachments tighten, care must be taken to not overtighten the nut. Doing so crushes the free-rolling washer.

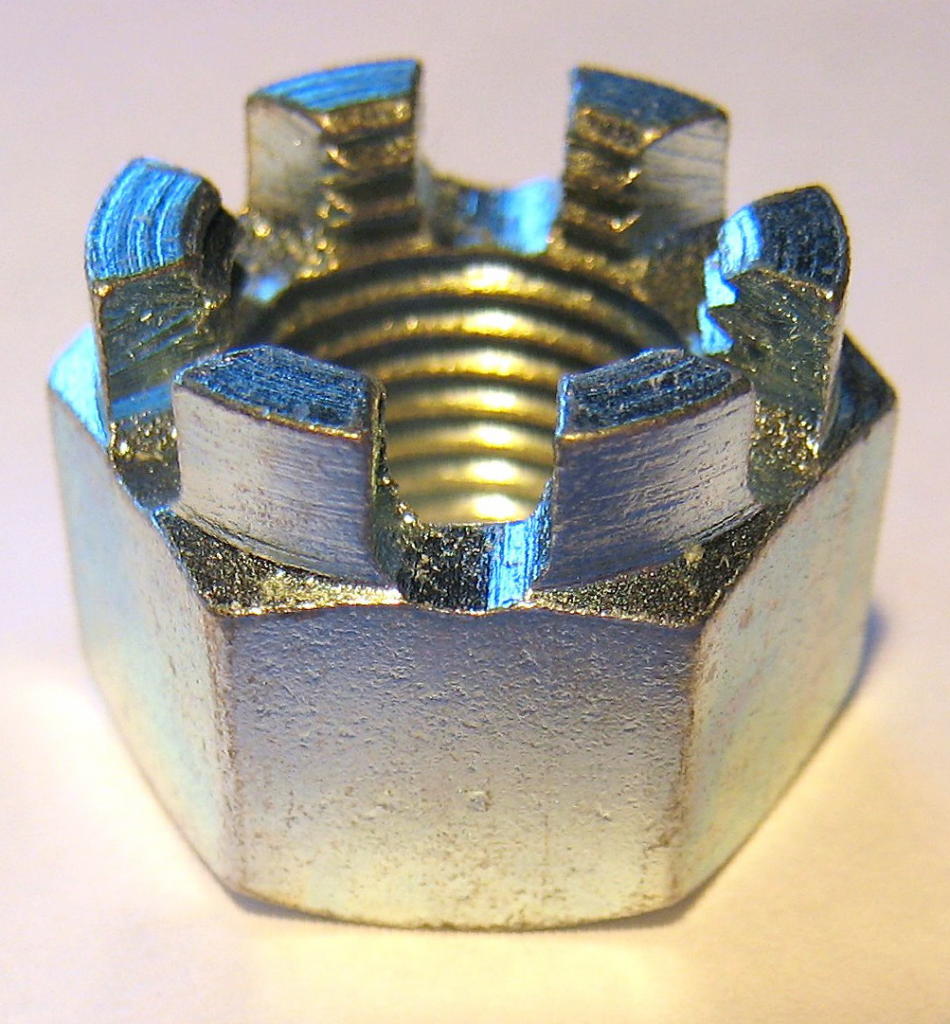

7. Castle

The castle-style provides a nut with slots cut into one end. It often employs in low-torque situations like holding a car wheel bearing in place. A common application is on axles to keep on wheels and bearings.

Sizes

Metric

Standard thread sizes are M3, M4, M5, M6, M8, M10, M12, M16, and M20 (typically specified in metric or M measures). Although lock nuts generally range from M25 through M50, M60, and even M85 are readily available online, these will cover most standard residential needs. A 10mm lock nut is a standard width for various projects and applications, but it is by no means the only width available. Standard locking nut widths include 5.5mm, 6mm, 7mm, 8mm, 11mm, 12mm, and 13mm.

Imperial

UNC (Unified coarse pitch threads)- Diameters range from 0.0730” to 0.2160”, and numbers range from No.1-64UNC to No.12-24UNC. Fractions measure larger diameters, and start at 1/4”-20UNC and go up to 6”.

UNF (Unified fine-pitch threads) – UNF thread diameters range from 0.0600” and go up to 0.2160” in diameter. Numbered lines range from No.0-80UNF to No.12-28UNF for these sizes. Fractions signify larger diameters, ranging from 1/4”-28UNF to 1.1/2”-12UNF. The UNEF size No.12-32UNEF is the smallest, while the series’ largest diameter is 1.11/16”-18UNEF.

Alternatives

There are a few alternatives to lock nuts that use different sealing methods and thus do not categorize as a lock nut. These include castellated nuts, thread-locking fluid, oval-shaped nuts, and safety wire.

Castellated Nut

It’s also known as a castle nut because it has three notches on one end that resemble the crenelated battlements of a castle. Castellated nuts are a type of positive locking system that keeps the nut in place and resists vibration.

These parts use in conjunction with a screw with a radial hole that has been pre-drilled. The nut fastens, and a pin is threaded through the screw’s notches and holes to keep the nut from spinning.

Thread Locking Fluid

Thread-locking fluid, often known as thread-locker, is a sort of glue that does what its name implies: it “locks” fasteners in place. It’s applied to a fastener’s threading — the threading where the fastener connects to a nut or item — then hardens and cures to keep the fastening from loosening.

Thread-locking fluid has been around for more than 50 years. Vernon K. Krieble, an American engineer and academic, designed it in the mid-1950s. Krieble went on to start Loctite after inventing the revolutionary new glue. Many other companies have since manufactured and sold thread-locking fluid.

Safety Wire

Safety wire, also known as locking wire, is a positive locking mechanism that prevents fasteners from slipping out due to vibration and other forces. The presence of safety wiring could also indicate that the clasps have tightened appropriately.

Depending on the use, safety wire comes in several gauges and materials. Stainless steel wire, such as 0.032 in (0.81 mm) diameter, is utilized in aircraft and racing applications. The wire often threaded through a hole drilled into a fastener or part, twisted and fastened to a second fastener or leg, and then turned again.