When HVAC systems go down or demand exceeds capacity, ventilation becomes more than a comfort issue. It becomes a matter of uptime, safety, and compliance. Temporary HVAC ventilation solutions are essential in data centers, hospitals, manufacturing plants, and event venues, especially during peak summer months or emergency outages.

Dynamic Rental Solutions delivers turnkey temporary HVAC systems across North America, offering chillers, portable air conditioners, and high-capacity air handlers (30 to 50 tons). In this article, we’ll explore how HVAC ventilation works, its importance, how to size it, and why renting it is often the most effective and efficient choice.

What Is HVAC Ventilation and Why It Matters

HVAC stands for Heating, Ventilation, and Air Conditioning. While heating and cooling tend to get the most attention, ventilation is the critical link that ensures both temperature regulation and indoor air quality (IAQ) are maintained. Ventilation involves the introduction of outdoor air, the circulation of conditioned air, and the removal of exhaust or contaminated air.

From an engineering perspective, ventilation systems must satisfy multiple performance criteria:

- Thermal Comfort: Maintaining indoor temperatures within ASHRAE Standard 55 guidelines.

- Air Exchange Rates: Delivering the necessary air changes per hour (ACH) for the application (e.g., 2–4 ACH for offices, 12+ ACH for healthcare environments).

- Humidity Control: Maintaining indoor relative humidity between 40–60% to prevent microbial growth and ensure equipment protection.

- Filtration & Air Purity: Meeting MERV or HEPA filtration requirements for industrial, healthcare, or pharmaceutical applications.

- Pressurization: Maintaining proper positive or negative pressure in critical zones such as clean rooms, isolation wards, or manufacturing lines.

Without proper ventilation, equipment overheats, IAQ deteriorates, and there is a compromise of regulatory compliance. In critical environments such as hospitals, data centers, and production plants, a ventilation failure can escalate from a comfort issue to a safety and uptime crisis within hours.

Typical Applications of Temporary Ventilation Systems:

- Emergency cooling for critical infrastructure such as data halls, server farms, and hospital wings.

- Planned maintenance where existing HVAC assets are intentionally taken offline.

- Supplemental airflow to address peak seasonal heat loads or production-driven heat gain.

- Indoor air quality (IAQ) management for healthcare, food processing, or clean manufacturing.

Components of a Temporary HVAC Ventilation System

A temporary HVAC system is a complex assembly of multiple components that work together as a single integrated system. Careful sizing of each component ensures that airflow, cooling, and humidity control meet the facility’s operational requirements and regulatory obligations. Here are some components of the system on offer at Dynamic Rental Solutions.

Chillers (90 – 400 Tons)

Chillers form the backbone of large-scale temporary cooling systems by extracting heat from closed-loop water or glycol coolant circuits. These systems are available in both air-cooled and water-cooled configurations, with selection driven by site conditions and available infrastructure. Air-cooled models reject heat directly to the ambient environment through condenser fans, making them ideal for standalone deployments. Water-cooled chillers interface with cooling towers or existing water supplies to achieve higher efficiency in dense or high-load applications.

Engineered for precision, DRS chillers are capable of maintaining supply water temperatures as low as 42°F (5.5°C). Thus, ensuring stable operation for mission-critical environments like data centers, pharmaceutical manufacturing, and hospital campuses. Compressor technologies, ranging from digital scroll to rotary screw, provide load-matching capabilities that improve part-load efficiency and reduce energy waste.

To streamline deployment, all units are trailer-mounted for mobility and have quick-connect couplings for piping, electrical tie-ins, and control integration. Therefore, allowing systems to come online in hours rather than days. This combination of flexibility and rugged mobility enables scalable, reliable, and rapid deployment of our cooling solutions.

Portable Air Conditioners (5 – 30 Tons)

Portable air conditioners deliver both cooling and ventilation for localized or smaller zones where precision environmental control is necessary.

Typical deployments, such as server rooms, laboratories, modular medical facilities, and office spaces, are areas with low tolerance to downtime. Hence, maintaining tight temperature tolerances is necessary.

These units are capable of rapid commissioning, with plug-and-play configurations that allow them to be fully operational within hours of arrival on site. Integrated condensate pumps eliminate the need for manual drainage, ensuring continuous operation even in high-humidity conditions. Advanced control features, such as programmable thermostats and microprocessor-based logic, enable operators to fine-tune setpoints and operating schedules. To enhance performance during partial load scenarios, hot gas bypass technology is incorporated to stabilize evaporator coil temperatures, preventing freeze-up and extending compressor life.

By combining compact mobility with industrial-grade reliability, portable air conditioners from DRS deliver a critical balance of speed, flexibility, and technical robustness for temporary HVAC needs.

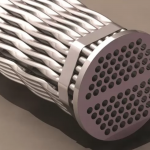

Air Handlers (30 – 50 Tons)

Air handlers serve as the backbone of temporary HVAC ventilation. They provide the airflow to distribute conditioned air across large interior volumes such as warehouses, hospital wings, or production areas. These units have high static-pressure fans, typically rated up to 6–8 inches water gauge (in. w.g.). Hence, they are capable of overcoming the resistance associated with extended duct runs, restrictive layouts, and multiple diffusers.

The Installation of variable frequency drives (VFDs) on motors helps to meet varying load profiles. Thus, enabling precise control of airflow while optimizing energy consumption and reducing mechanical wear. Filtration systems ranging from MERV 8 to MERV 13 are integrated to comply with indoor air quality (IAQ) requirements set by ASHRAE and local building codes, capturing particulate matter in environments where clean air is mission-critical. In addition, it is possible to fit these air handlers with dehumidification coils. Thus, providing latent cooling for humidity-sensitive operations such as pharmaceutical storage, data centers, and healthcare facilities.

For operational flexibility, configure units to deliver either positive or negative pressure. This depends on the containment or pressurization strategy requirements of the application. Combining airflow performance, advanced control, and compliance-ready features makes DRS’s temporary air handlers a reliable solution for critical ventilation challenges.

Additional HVAC Ventilation Components

- Flexible ducting: High-tensile insulated ducts can minimize static pressure losses while withstanding rugged deployment environments.

- Power distribution gear: UL/CSA-compliant systems with integrated circuit protection and disconnects.

- Control panels and thermostats: Programmable digital controls for temperature and humidity, including alarm integration for out-of-range parameters.

- Monitoring sensors: Instrumentation for airflow (CFM), temperature, RH, and pressure differential, with options for remote monitoring via BAS (Building Automation Systems).

All DRS systems are factory-tested, preconfigured, and delivered as turnkey packages, minimizing onsite commissioning time.

When to Rent HVAC Ventilation Systems

Temporary HVAC ventilation provides engineered redundancy during four primary operational scenarios:

Emergency Response

When critical HVAC infrastructure fails, whether through chiller breakdowns, rooftop unit (RTU) malfunctions, or a central plant outage, the immediate loss of cooling and ventilation can jeopardize both uptime and occupant safety.

Power failures compound this risk by shutting down building-wide air circulation, leaving enclosed spaces vulnerable to overheating, equipment failure, or unsafe indoor air quality. In these scenarios, temporary HVAC ventilation systems from DRS can be mobilized within hours, restoring airflow and thermal control during disaster recovery or remediation operations.

Planned Maintenance

Large facilities often face scheduled downtime for major HVAC work or even in renovation work, including the replacement of chillers, RTUs, or entire central plant systems. During these periods, operations cannot simply halt; production lines, healthcare environments, and controlled spaces must remain conditioned. Temporary HVAC ventilation systems provide seamless coverage during maintenance, ensuring that airflow, temperature, and humidity control remain uninterrupted.

Supplemental Capacity

Permanent HVAC systems are capable of handling expected design loads, but extreme operating conditions can quickly exceed that baseline. Seasonal heat waves, for instance, can cause indoor thermal loads to spike beyond the capacity of installed chillers and RTUs.

Similarly, high-intensity production environments, such as foundries, chemical processing plants, or advanced manufacturing lines, generate excess heat loads that strain existing infrastructure. In these cases, supplemental HVAC capacity is essential to protect both workers and equipment.

Special Events and Temporary Structures

Whether supporting a 10,000 sq. ft. warehouse or a hospital ICU wing, DRS engineers right-size systems to meet both cooling demand and regulatory air change rates.

Additionally, DRS is fully equipped to handle the following special events/temporary structures:

- Indoor/outdoor venues, exhibitions, and large gatherings

- Mobile healthcare testing and treatment sites

- Pop-up retail, military, or emergency housing structures

Sizing HVAC Ventilation Systems: What You Need to Know

Accurate sizing is critical. Oversizing increases energy consumption and operating costs; undersizing reduces performance and risks equipment overload.

Engineering Considerations

- Cooling load (BTU/hr or tons): Based on floor area, heat gain from equipment, lighting, occupancy density, and solar exposure

- Air changes per hour (ACH): Determines required air volume turnover per industry standards (ASHRAE 62.1, CSA Z317.2 for healthcare, etc.)

- Airflow rates (CFM): Must be matched to thermal and filtration requirements while maintaining appropriate duct velocities

- Humidity control: Essential for pharmaceutical, healthcare, and food processing environments where RH stability is critical

- Static pressure losses: Dependent on duct length, diameter, and fittings, influencing fan and motor selection

DRS Engineering Support

It is never a good idea to rely on guesswork when it come to ventilation systems. DRS provides precisely engineered temporary HVAC solutions for maximum efficiency and compliance.

- In-house load calculations performed to ASHRAE standards

- On-site walkthroughs and data collection when required

- CAD layouts and airflow modeling for complex multi-zone facilities

Technical Features of DRS Ventilation Equipment

All DRS systems are designed for demanding industrial and commercial conditions, with equipment maintained to manufacturer and ISO standards. All units undergo pre-deployment functional testing and are supported by DRS field technicians to ensure uninterrupted operation.

Chillers

- Digital scroll or screw compressors with staged capacity control

- Ambient-rated for performance in extreme climates (−20°C to +45°C)

- Trailer-mounted with quick-connect piping for rapid deployment

Air Handlers (30–50 tons)

- VFD-controlled motors for precision airflow adjustment

- High-efficiency coils and MERV 8–13 filtration options

- Forklift pockets and lifting lugs for safe handling and installation

Portable AC Units

- Plug-and-play with integrated electrical disconnects

- Built-in condensate pumps for continuous unattended operation

- Hot gas bypass technology for low-load stability

Advantages of Renting HVAC Ventilation from DRS

Dynamic Rental Solutions is more than an equipment provider; we are an engineering partner in operational continuity and environmental control.

Here’s where DRS excels:

- Rapid Deployment: Equipment delivered and installed in as little as 24 hours.

- Scalable Fleet: Capacity from 5 to 500+ tons, configured to exact requirements.

- Engineering Support: Load calculations, system modeling, and onsite integration.

- Cost Efficiency: No capital investment, service contracts, or depreciation risk.

- 24/7 Availability: Emergency response teams on standby.

Contact us today for more details, and let us set up your next HVAC ventilation system.