Flange gaskets are crucial in ensuring the proper functioning ofof piping systems. Gaskets provide proper sealing between flange connections in a system in order to prevent the leak or escape of the fluid being moved in the system. Gaskets are used in many different industries and play a large role in process system performance despite their small size. In this article, you will learn about the purposes of gaskets, gasket types, the installation process, and failure diagnosis.

The Purpose of a Flange Gasket

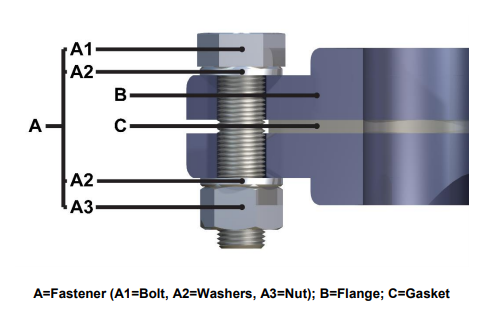

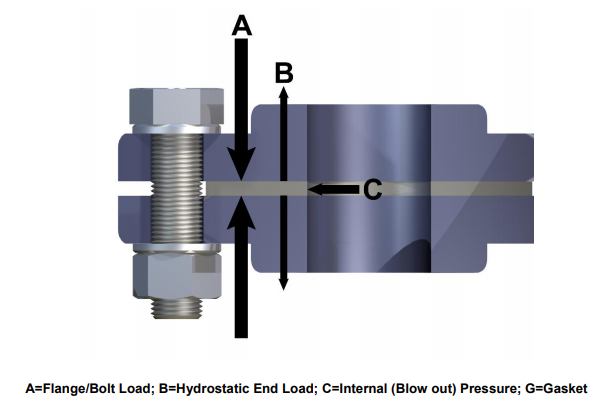

Flange gaskets work in between flange connections to ensure a complete seal and prevent leaking of the working fluid inside a system. Gaskets are typically rubber but vary in construction material type based on client specifications and process media requirements. Flanges are typically bolted together and have a gasket in between them to ensure a proper seal. Gaskets must be able to withstand the compressive force of the flange seal, the pressure of the fluid inside the system, and also work against any failure of the flange as a means of failure prevention. Some operations conditions a gasket may encounter are misalignment, surface imperfections, and even surface scoring. Gaskets may also experience thermal expansion which makes thermally resistant material such as metal in some heated applications the ideal type of gasket. Through all these conditions, a gasket must maintain a proper seal between the flanges in a system without any major deformations or failures.

Types of Flange Gaskets

The three main types of flange gaskets are non-metallic, semi-metallic, and metallic. The performance and different type of applications dictate the type of flange gasket that is ideal for each different application

Non-Metallic Gaskets

Non-metallic gaskets also known as soft gaskets are typically made of rubber and usually ring type of gaskets although custom shapes may also be utilized. Non-metallic gaskets are useful for corrosive fluids in low to high temperature applications. The main limitation for this type of gasket is the amount of pressure it may handle. Typically non-metallic gaskets are useful for low to medium pressure systems and may pose danger if used for systems at a higher pressure. Some non-metallic gaskets are made from a material cut from a compressed sheet of fibers that are manufactured according the industrial specifications for gaskets as set by the ASTM, the American Society of Testing and Materials. Other materials including rubber are manufactured and distributed with specified standards in mind.

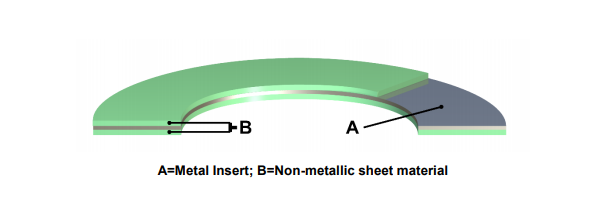

Semi-Metallic Gaskets

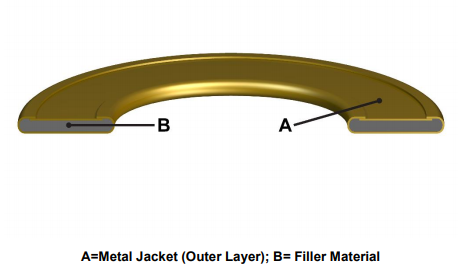

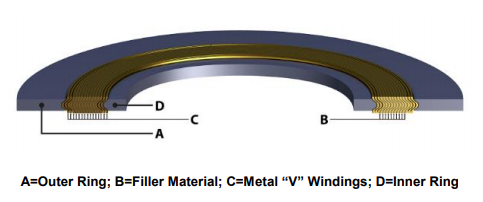

Semi-metallic flange gaskets are made from a composite of soft materials and metals to capitalize on the advantages of each type of material. Non-metallic gaskets provide for better sealing capabilities, while metallic gaskets provide increased durability. Semi-metallic gaskets allow for a good balance between sealing and durability and sees applications in a variety of temperature and pressure situations. Construction typically is a core metal alloy that is coated or covered with a specific non-metallic gasket substance. Some semi-metallic gaskets may also be jacketed in metal, covered in metal, or spiral wound.

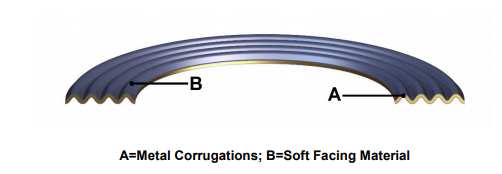

Metallic Gaskets

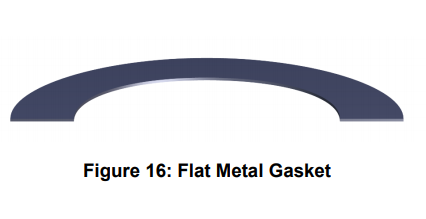

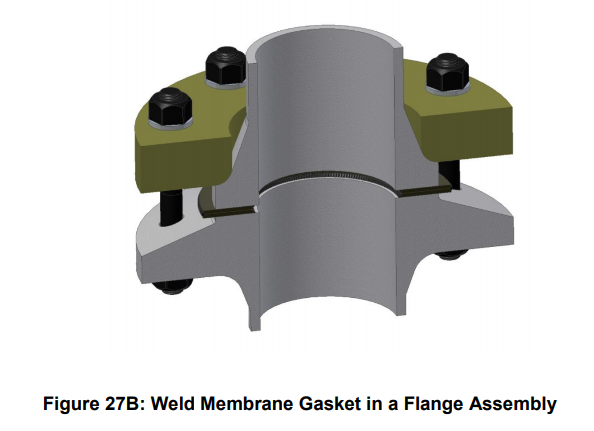

Metallic gaskets are made from metal or a composite of different metals. Metallic gaskets are best for high pressure and temperature applications due to their resistance to high heat. Metallic seats are less ductile than non-metallic seats, requiring much greater pressure for a proper seal. The metal gaskets come as flat, grooved , and other different types of configurations. Some metallic flanges may also be welded between flanges to ensure an even tighter seal, but is a method that is much harder to maintain. Material of construction for metallic gaskets depends on the particular application.

Gasket Installation

Installation of a gasket requires that the proper seating be created depending on the system application. For non-metallic soft gaskets, typical install is a simple as ensure proper seating between the flanges and tightening or installing the flange around the gasket to proper specifications. For metallic gaskets that require welding, proper welds are necessary for good seating and proper installation. Some gasket applications require the correct placement of the gasket should the flanges have custom shaped grooves or shapes in which the gasket should be seated.

Failure and Maintenance

The main considerations for maintenance of a gasket and associated failure are the seating conformity, material permeability, internal pressure stress, and temperature related wear. All of these are the main factors of aging in gaskets other than just time, and are important considerations to note when identifying causes of failure and maintaining proper sealing.

Flange Seating

Failure in a gasket may occur if the specified amount of compression between the flanges on the gasket is not maintained. This may occur from simple loosing over time, irregularities in operation, or even just expected wear from a piping system. Ensuring the proper compression on the gasket is being met is crucial to maintaining a good seal and seat and to prevent failure.

Material Permeability

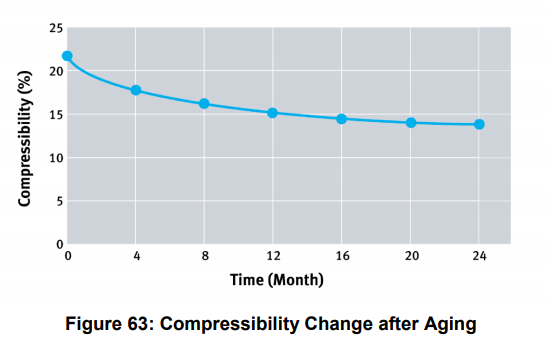

The material of the gasket is expected to wear out over time. It is expected that over the life time of a gasket more and more compression is needed to ensure no leaks occur as the gasket wears out over time and is less able to maintain proper sealing. Most of the time, replacing the gasket is necessary once the required compression exceeds safe limits.

Internal System Factors

Pressure from the system itself plays a role in deforming and aging gaskets. Through the use of gauges and other instrumentation it is vital to ensure the system itself is running as expected as any extreme variations in internal pressure may place extra stress on the gasket causing premature aging or in worst cases, failure. Similarly, if the system working fluid is a chemical or any type of corrosive fluid, it is important to watch for corrosion in a gasket and replace them accordingly.

Temperature

For higher temperature and pressure systems, thermal stress may cause flanges to loosen which in turn reduces compression on the gasket that may cause for leaks. It is important to consider the side effects of an elevated temperature system and proceed with the necessary caution such as re torqueing any loosened flanges from system temperature.

Poor Seating

If the gasket is under loaded, meaning the compressive force is not enough or un even across the gasket due to poor bolting, leakage and failure may also occur. Uneven compression leads to uneven wear which also is a major cause for premature failure. Similarly, over compression of a gasket may cause for failure from cracking or ripping within the gasket.

Reusing Gaskets

Gaskets are expected to be used only once as the wear from a single use heavily deforms the initial shape of a gasket. It is important to identify and note whether a gasket has already been used and to not use it for more than a single application.