A small fabrication shop on the northwest side of Houston has been making their way onto a lot of bid lists. Five Fab recently moved into a state of the art, 12,000 square feet manufacturing facility. Punchlist Zero caught up with Tony Kennon of Five Fab to see what the fuss was all about.

So tell me about Five Fab. What’s the origin story?

FF: Well, we are a fabricator and when we started there were five guys. So we just kept it simple and called it Five Fab. One of the five original guys left us so I guess its really Four Fab now!

All of us having been fabricating products for years and most of us have worked together for years as well.

What are the products that you do best?

FF: We are a code shop and do a lot of pressure vessel work. Piping is big for us as well and we also do structural work.

Five Fab has quality management system approved by ASME and has an ASME Section VIII Div 1 U-Stamp and R-Stamp. We have certified welding procedures for SMAW, GMAW, FCAW and GTAW welding processes on carbon, low temp & stainless steel material. We also specialize in the B-31.1, B31.3, B31.4 and B31.8 piping code.

NDE is provided by a Certified Laboratory and can include RT, MT, UT or PT. Mechanical Assembly, Insulation, Instrumentation & Electrical Assembly can also be provided for your project.

Our preferred range of ASME Code Vessels and Pipe Spools is up to 60” OD x 35 ft long and up to 40,000 pounds. Our preferred range of Skid Packaging is up to 10’ W x 35’ L x 14’ H x 40,000 pounds.

Why do you think Five Fab has done so well?

FF: We started small and put money right back into the business. We started at a hole in the wall facility at the beginning that didn’t look like a manufacturing facility. But, by starting small, it allowed us to find the right facility at the right time once the work started coming in. Now our facility looks like a manufacturing facility and it is a good look for our business.

What sets you apart from other fabricators?

FF: I can give you the usual cliche things that everyone else says like the quality of work and the craftsmanship that we put into each weld. We do have all that. But what really sets us apart are the relationships. We know a lot of people from being in the industry so long. They trust us and we trust them.

To potential new clients, I would say you aren’t going to find a vessel shop that is as flexible as we are. We do a lot of quick turn work and we can expedite for a reasonable fee. We keep our pricing open and transparent. I’m the point of contact with all of our customers and give you the same level of service no matter the size of your business.

What are your goals for 2019?

FF: We would like to keep improving our infrastructure. The parking lot could be improved. We are looking at maybe adding an overhead crane. Five Fab will keep improving their facilities. We would like to keep bringing work in, because we have plenty of space to do so.

Anything else you would like to say?

FF: We think it’s a really good time for the energy sector. While oil prices are low, the environment continues to look good for shales plays and the development of new pipelines. With America becoming an exporter rather than an importer, the future of energy is looking good for this country.

Five Fab Energy is a three year old manufacturing company, specializing in the fabrication of pressure vessels, piping, and structural skids.

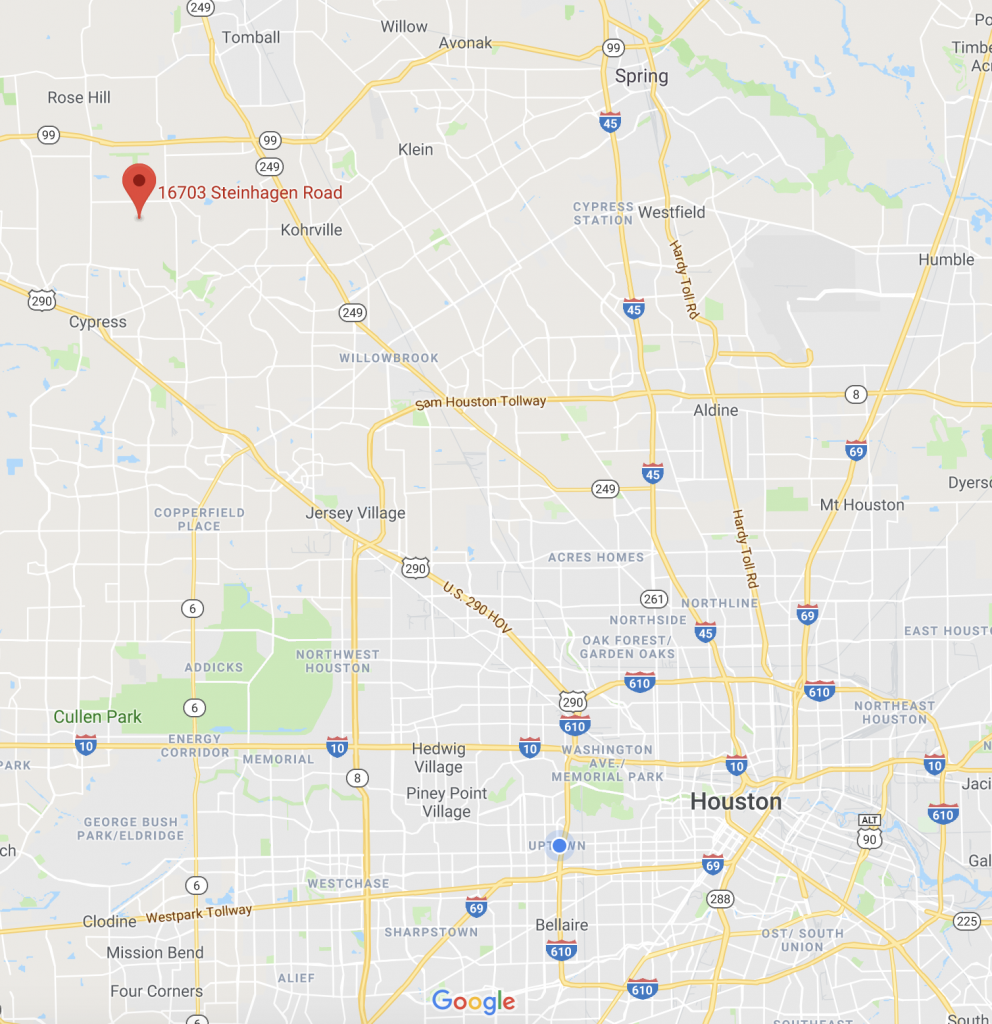

Five Fab is located at 16703 Steinhagen Road in Cypress, Texas. For inquiries, please contact tkennon@5fabenergy.com.