In this article, you will learn the function of self-tapping screws, sizes, differences from standard and self-drilling screws, materials, and when to use them.

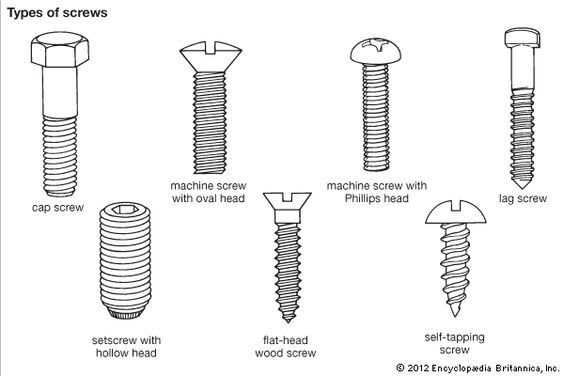

First, what are self-tapping screws? Self-tapping screws are a subset of sheet metal screws. The two main types of sheet metal screws are self-tapping and self-drilling screws. As the name implies, they usually secure sheet metal but also work with plastic, fiberglass, and wood.

Self-tapping screws tap their own hole as they drive into the material. Self-tapping screws, excluding wood screws, are a specific form of thread-cutting screw designed to produce a thread in relatively soft or sheet materials.

They are also suitable for objects that need regular maintenance and perform well when fastening two different types of materials together. The tip of these screws pierces into a pilot hole.

Function

Tapping screws usually secure thin sheet metals and have a sharp point like a pencil. In most cases, they require a pre-drilled pilot hole. The pilot hole often is punched on a press. Once the screws engages, it taps its way through the subject materials. This creates a tight friction fit between the threads. This helps fight vibrational loosening and allows the parts to be separated if needed.

Here’s a tip on how to use this type of screw:

Position the screw straight in line with the hole and turn it in, one or two turns, by hand. This allows the screw to leave in the spot as you pick up your screwdriver or drill machine. Using short movements, fasten the self-tapping screw in place using a Phillips or flat head screwdriver or drill bit. Ensure these screws go in straight, and do not over-tighten as this could cause the head to strip.

Sizes

Does the size of the self-tapping screw matter? Choosing the incorrect screw size for the job can be risky. The screw isn’t the correct screw for the job if it’s too long or too small. If the screw doesn’t disappear entirely or is too loose, remove it and replace it with a more appropriate variety.

Most engineered drawings provide detail on where to locate the self-tapping screws. When specifying the screw sizing and location, consider the thickness of the material, finish, client specifications, and AISC codes (if applicable). It’s also worth noting that expanding a too small pilot hole with a larger screw is much easier than making a large hole smaller.

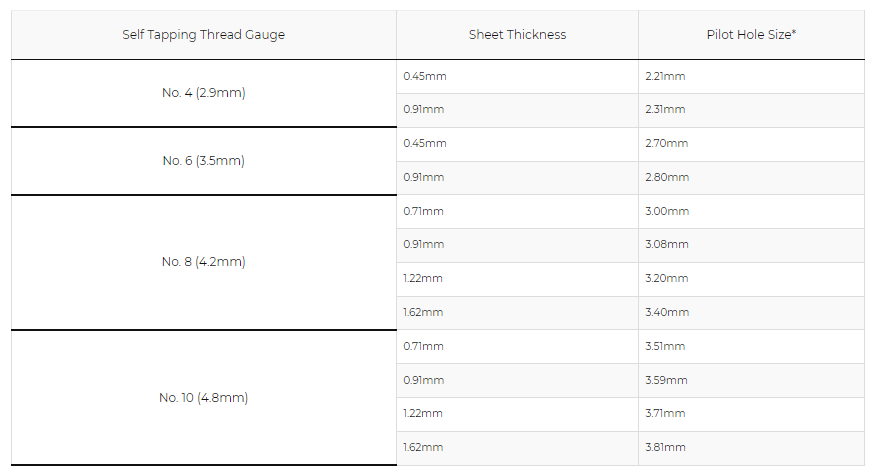

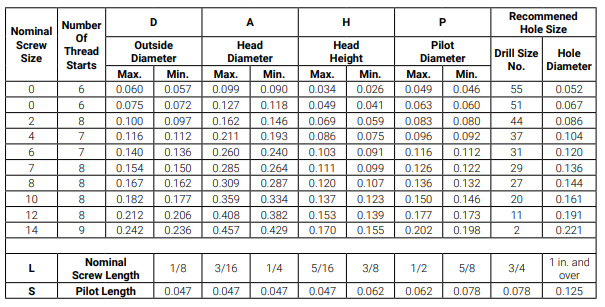

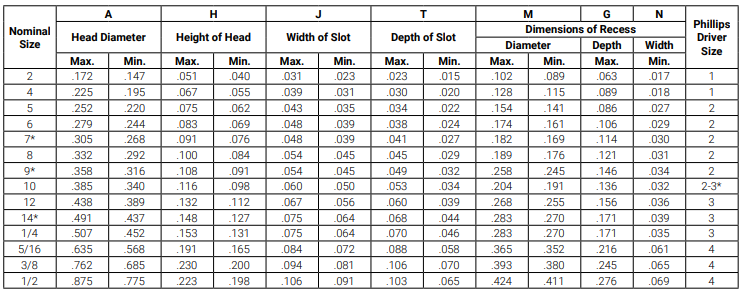

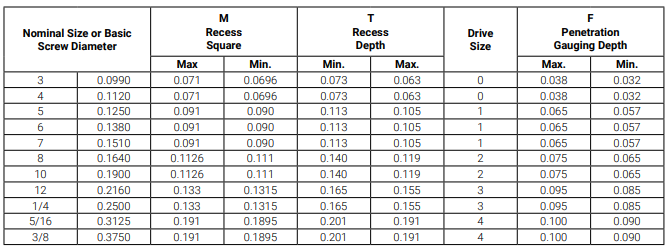

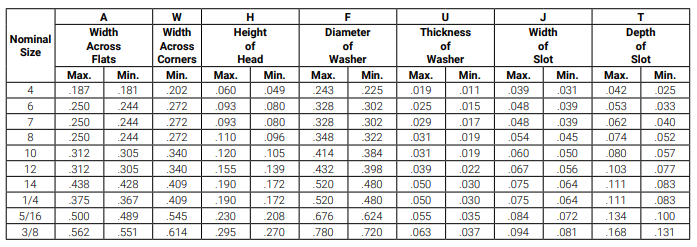

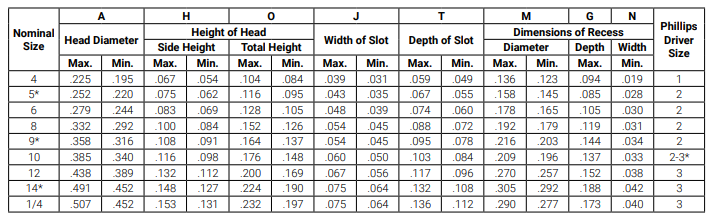

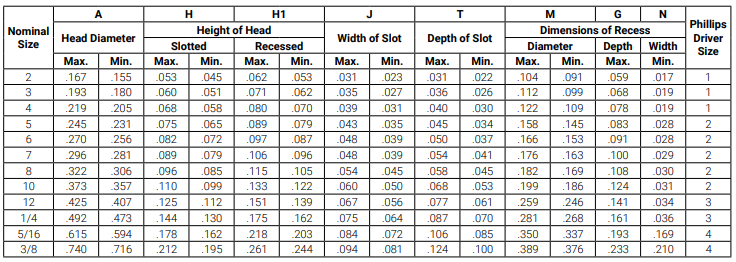

A pilot hole should be between the minor and principal diameters of the screw thread as a rough reference. However, this will always fluctuate based on external conditions. The table below lists many suggested hole sizes.

Courtesy: American Fastener

Courtesy: American Fastener

Courtesy: American Fastener

Courtesy: American Fastener

Courtesy: American Fastener

Courtesy: American Fastener

Self-Tapping Screw vs. Normal Screw vs.

Sheet metal processes can create pilot holes without much extra cost or effort. Self-tapping screws insert into the pilot holes and create threads. Sheet metal pilot holes often are punched via a machine with threading added by the manual process of applying screws to sheet metal.

This contrasts with traditional machine screws, which generally require a pre-threaded hole to secure the connection.

Self-drilling screws have a sharp point designed to dig into the sheet metal. In addition to drilling out the entry point, self-drilling screws also create the hole’s thread pattern. Self-drilling screws are not always preferred because the pilot hole precisely locates the screw’s entry point. Thus, the added functionality of self-drilling is not required. Also, penetrating the self-drilling screws into the metal often requires a great deal of effort.

Materials

Stainless steel is the most prevalent material because it provides a good blend of strength, durability, and rust/corrosion resistance. For added robustness, certain self-tapping screws coat with other metals such as zinc. Aluminum is usually less expensive than stainless steel lacks the same degree of strength and hardness.

When To Use Self-Tapping Screw

Self-tapping screws perform best when drilled into hard materials like metals. They do not employ well in soft materials such as wood. The blades can safely tap a hole into the material without causing fractures or cracks when used in stones and bricks.

Self-tapping screws see primary service in the industrial sector. They make sense in situations where a screw pattern isn’t yet formed. These screws usually secure metals such as steel and aluminum, but also attach materials with a significant thickness. These screws are great also for connecting air conditioning equipment and roof canopies. This type of equipment may pull apart when conventional, pre-threaded holes and fasteners are used.