C-Purlins, also known as cee purlins, are shaped like the letter C and provide structural support for wall and floor beams. In this article, you will learn more about C-Purlins, review a C-Purlin span chart, and compare C-Purlins vs. Z-Purlins.

What are C-Purlins?

A C-Purlin is a type of structural member used in the construction of roofs and walls in steel buildings. It is shaped like a “C” and is used to support the load from the roof deck or wall cladding. C-Purlins are typically made from cold-rolled steel and come in a variety of sizes to suit different building designs. Their versatility, ease of installation, and cost-efficiency make them an attractive option for many builders and architects. Below are some common places where you can find c-purlins:

- Residential Construction: C-Purlins support residential homes and other small buildings, where they are used to support the roof deck and wall cladding.

- Commercial Construction: C-Purlins see use in larger commercial buildings such as warehouses, factories, and retail centers. They may support the roof deck and wall cladding and can be used in combination with other structural members such as girts and steel beams.

- Agricultural Construction: C-Purlins also find frequent use in agricultural buildings such as barns, stables, and sheds, where they support the roof deck and wall cladding.

- Prefabricated Structures: Prefabricated structures such as modular buildings, portable buildings, and container structures often use C-Purlins.

- Industrial Construction: C-Purlins are used in the construction of industrial buildings such as power plants, oil refineries, and chemical plants.

Red Oxide Purlins vs. Galvanized Purlins

C-Purlins are available in two types of finishes: red oxide (or ‘red iron’) or galvanized. Manufacturers apply these finishes to the supports in order to prevent rusting and other potential damages.

Red oxide purlins are the more simple finish, as it is just a red spray paint primer finish. It does help prevent initial rusting, but will not prevent further rusting when exposed to external weather conditions.

Galvanized purlins are finished with zinc-alloy plating. This helps the material become extremely corrosive resistant, even in tough conditions. Galvanized purlins are popular in chemical plants or coastal environments where oxidization chances are increased.

So, which finish is the better choice? Structurally speaking, neither red oxide nor galvanized finishes provide a particular advantage over the other. Price-wise, there is a significant difference. Red purlins tend to be between 25-35% cheaper when compared to galvanized purlins.

E-houses typically use galvanized purlins which fit with the requirements of the overall structure. Red purlins are more commonly used in commercial buildings.

The C-Purlin Span Chart

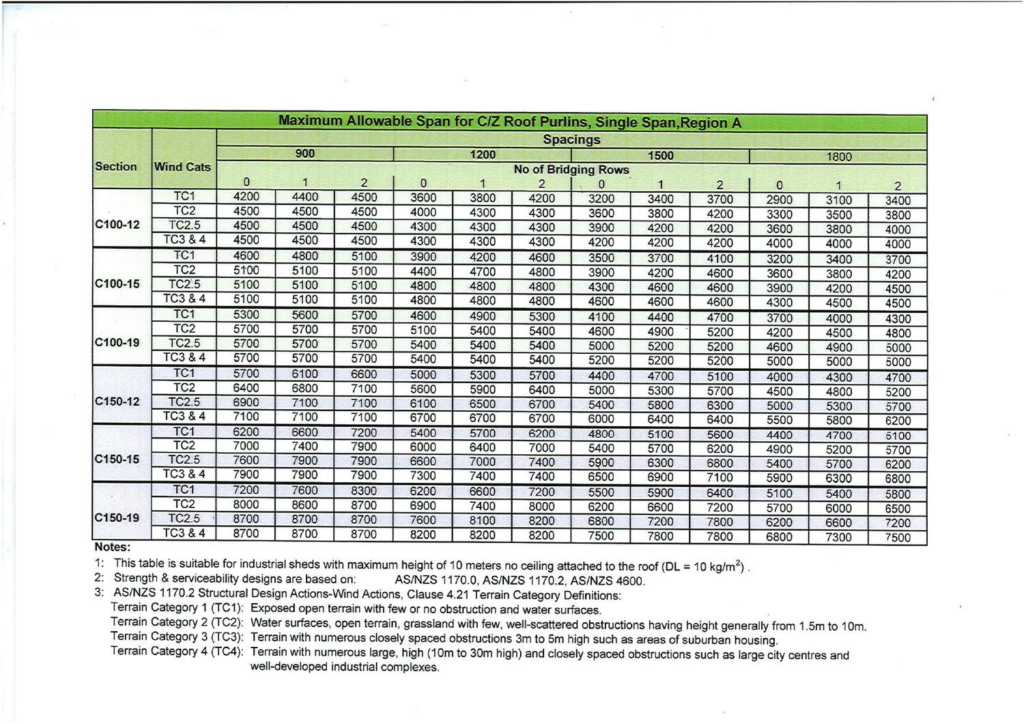

A C-Purlin span chart is a table or chart that provides information on the maximum allowable span for a C-Purlin of a given size and gauge (i.e. thickness) when used in a specific load-bearing application. The chart typically includes information such as the size and gauge of the C-Purlin, the type of load (i.e. roof or wall), the spacing of the purlins (i.e. the distance between the supports), and the maximum allowable span in feet or meters.

The values provided in the chart are determined by engineering calculations and testing and are based on the strength and load-bearing capacity of the material, as well as the specific application and conditions in which it will be used. The span chart is used by architects, engineers, and builders to determine the appropriate size and spacing of C-purlins for a given construction project. Below is an example of a common c-purlin span chart:

C-Purlins vs. Z-Purlins

Z-Purlins are another type of horizontal beam that help form the roof and walls of a structure. The name originates from its unique ‘Z’ shape, which helps in overlapping several joints.

Z-Purlins’ ability to connect multiple objects together allows it to be much stronger and structurally sound when compared to c-purlins. Because of this, many large-scale buildings choose Z-Purlins to be their support of choice.

C-Purlins and Z-Purlins can combine with other structural members to create a complete steel framing system. The choice of which type of purlin to use will depend on the specific requirements of the project. This includes the type of load, size and spacing of the purlins, and cost considerations.

Conclusion

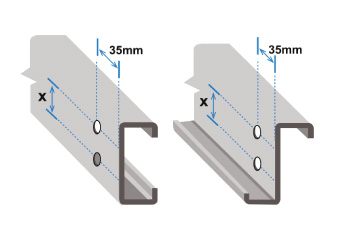

C-Purlins serve as an essential element in supporting walls, beams, and flooring of nearly all structures. C-Purlins may span long lengths and provide strong durability. No side drilling and cutting are required to assemble them into a broader metal structure. As such, C-purlins will continue to find frequent industry use long into the future.