Stub-in pipe refers to a branch connection between a pipe and a header. Making this connection involves drilling a hole into the header of the run pipe and fitting the stub-in pipe into the hole. In this article, you will learn how stub-in pipe works, its use vs stub-on, as well as the use of a stub tube.

How Stub-in Pipe Works

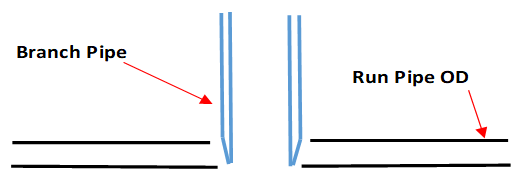

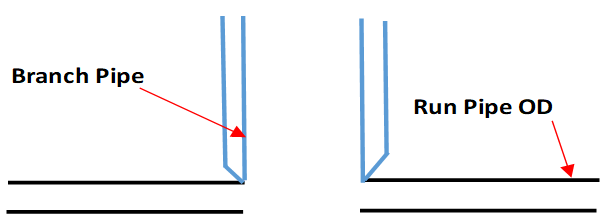

Typically, when the difference between the run pipe and a branch pipe is more than one pipe size, then stub-in provides a suitable connection option. Making this connection involves drilling a larger hole than the branch pipe’s outer diameter. Then, the hole and the main pipe are beveled to allow for a full penetration weld. Next, butt-welding the main pipe and branch pipe fits them together. Moreover, this type of connection offers cost savings because there is no need for fittings. Also, the installation requires just one weld around the stub hole, unlike some connection types that require three around the two joints to the main/header pipe and connections. For this type of connection, the branch pipe extends inside the header pipe.

Stub-in Pipe vs Stub-on Pipe

Both stub-in and stub-on are types of pipe branch connections. Moreover, these types of connections are useful in the distribution of fluids, the provision of drains, accumulation of fluids, and for the installation of instruments on header pipes. When designing a joint, the stress intensity factor (SIF) in a stub-in and stub-on are much higher than in weld-olets and ASME tees. Thus, an exhaustive stress analysis is prerequisite to using these types of connections. In addition, the high levels of SIF means that stub-in and stub-on are not ideal for severe cyclic applications, high pressure and temperature applications, and category ‘M’ fluid service applications.

Although stub-in and stub-on have similar features, they also have several differences.

| Stub-in Pipe Connection | Stub-on Pipe Connection |

| Stub-in connections suit scenarios where the difference between header/run pipe and branch pipe exceeds one size. | Stub-on connections apply when both pipes are of the same size, or there is a one-size difference. |

| For this connection type, the pipe weld between the run and branch is a butt-weld. In addition, this type of weld is more difficult to execute. | Stub-on provides a fillet weld type, which is much easier to execute. |

| With a more robust weld connection, stub-in can withstand more pressure. Although, both connections suit only low-pressure applications. | Due to the nature of the fillet weld connection, stub-on has less pressure capacity than stub-in. |

| The edge of the branch pipe is in line with the run pipe internal diameter. | While the edge of the branch pipe for a stub-on pipe, lies on the outside diameter of the run pipe. |

| Comparatively, this has more weld strength value. | Stub-on welds have less strength value. |

Stub Tube

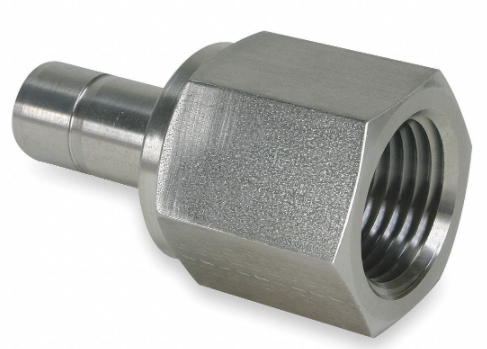

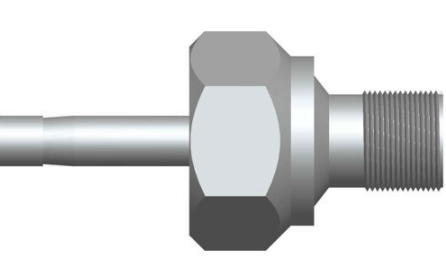

A stub tube is a type of connection just like a stub-in pipe or stub-on pipe. It refers to a short tube that is welded to a header or pressure vessel to serve as an attachment point to additional parts. Moreover, these additional parts could be pipes or various kinds of equipment. Also, in the case of pipes, they could be of the same diameter, or of different sizes. Typically, stub tubes are made of steel, with a weld attachment to a header on one end, while threading is done on its other end. This other end, the receiver or receiving end, is what provides a means of attachment to other equipment. In addition, this threading could be external or internal depending on if it is a male or female stub tube adapter respectively.

Because of its threading, stub tubes provide flexibility for the attachment of a range of fittings, using union nuts and adapters. As a result, many equipment manufacturers make use of this flexibility for a variety of connections as technology evolves.

In summary, taking a critical look at the stub tube and stub-in connections shows that they share similarities. First, they both penetrate the internal diameter of the run or header pipe. As a result, they both deploy butt-welds in attaching to the run pipe. Their difference lies in the flexibility of stub tubes, which can connect to a variety of fittings. This contrasts with stub-in which is basically for just pipes.