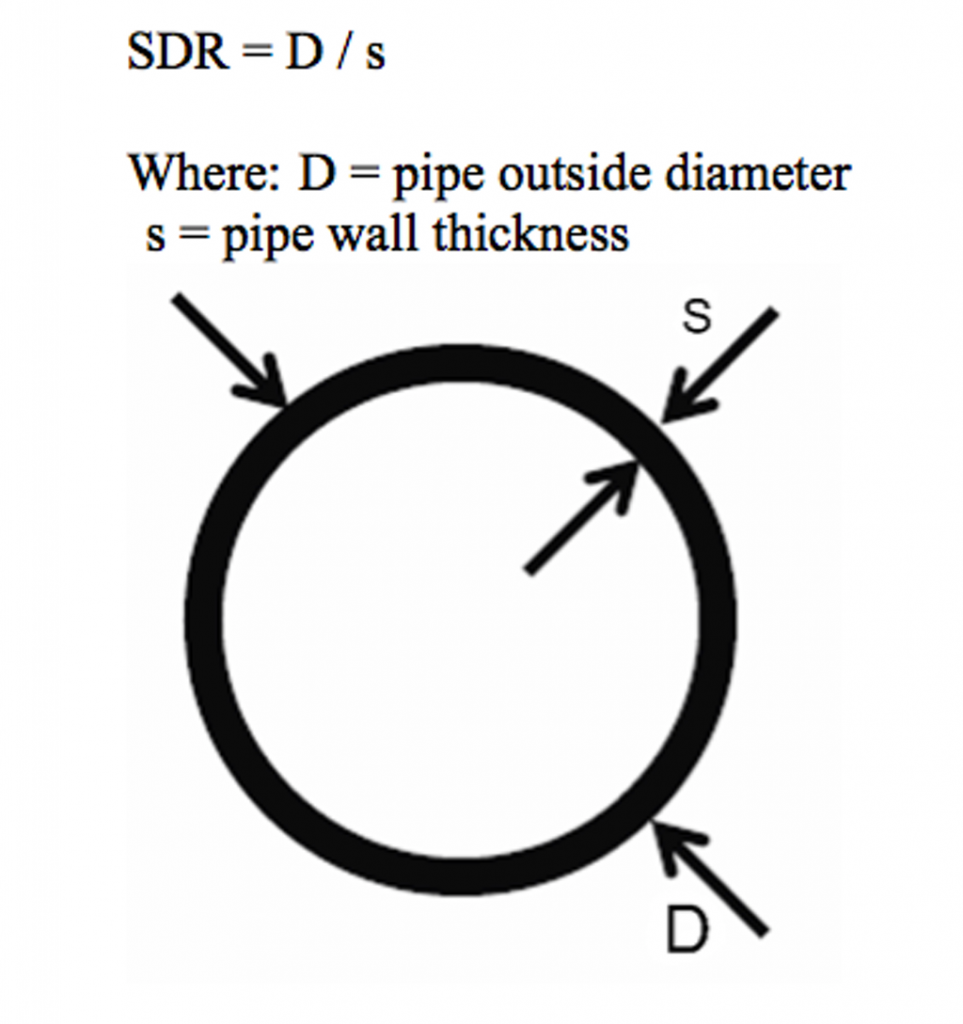

SDR 11 vs. SDR 13.5 both categorize under the SDR rating system for the pipe. The SDR (standard dimension ratio) is a pressure pipe rating method. The SDR increases as the pressure rating decreases. “D” stands for the line outside diameter (mm, in), while “S” stands for pipe wall thickness in mm or in. SDR provides excellent tensile and impact strength.

In this article, you will learn about the SDR 11 pipe, SDR 13.5 pipe, and compare each pipe’s properties.

SDR 11

SDR 11 denotes that the outside diameter is 11 times the wall thickness. The pipe’s outer diameter equals the minimum wall thickness multiplied by the SDR. As a result, SDR 11 pipe is part of the SDR family and provides a designation for how well it withstands pressure. Internal pressure for SDR 11 pipe is around 130 psi.

The SDR 11 pipe may fashion from HDPE, ABS, PVC, CPVC, and other materials. The vast majority of installations are PVC or HDPE. The majority of SDR-11 pipe transports liquids under low pressure.

SDR 13.5

SDR 13.5 is a multi-purpose continuous length smooth solid wall conduit. It is typically manufactured of HDPE or PVC, depending on the process requirements. It comes with either smooth or ribbed inner walls.

These pipes and fittings are used for agriculture, irrigation, water supply, industrial process lines, swimming pools, firefighting mains, etc. These pipes are generally superior to C.I., D.I. or R.C.C. pipes. They offer advantages like lightweight, easy and fast installation, excellent corrosion and chemical resistance, high flow rates, and long life at a low price point.

SDR 11 vs. SDR 13.5 Pipe Properties

Material Type

Like the other SDRs, polyvinyl chloride frequently makes these pipes. PVC is a high-strength thermoplastic material commonly utilized in pipelines, medical equipment, wire and cable insulation, and other applications. In fact, it is the world’s third-most-produced synthetic plastic polymer.

Despite these benefits, PVC is not heat resistant. As a result, PVC should only be utilized in non-potable water applications and not for inhaling air.

HDPE (High-Density Polyethylene) is also commonly used. HDPE provides better dampening and shock absorption than PVC and often provides a superior choice in industrial applications.

Wall Thickness

The wall thickness can be calculated using internal measurements (ID) and exterior dimensions (OD). Subtract the ID from the OD and divide the result by two. This is the thickness of the wall.

| Nominal Size (inches) | Outside Diameter (inches) | SDR 11 Wall Thickness (inches) | SDR 13.5 Wall Thickness (inches) |

| ¾ | 1.046 – 1.054 | 0.068 | 0.078 |

| 1 | 1.310 – 1.320 | 0.084 | 0.097 |

| 1 1/4 | 1.655 – 1.665 | 0.107 | 0.123 |

| 1 1/2 | 1.894 – 1.906 | 0.123 | 0.141 |

| 2 | 2.369 – 2.381 | 0.153 | 0.176 |

| 3 | 3.492 – 3.508 | 0.226 | 0.259 |

| 4 | 4.491 – 4.509 | 0.290 | 0.333 |

The above SDR pipe dimensions are provided for informational purposes only. Official dimensions should be provided by the manufacturer.

Corrosion Resistance

Because SDR 11 and SDR 13.5 fashion from PVC or HDPE, neither corrodes from soil or water. These plastic components provide unique physical properties that protect it from corrosion and chemical attack from acids, alkalies, salt solutions, and other chemicals. Polar solvents, such as ketones and aromatics, destroy PVC and HDPE quickly.

Flexibility Strength

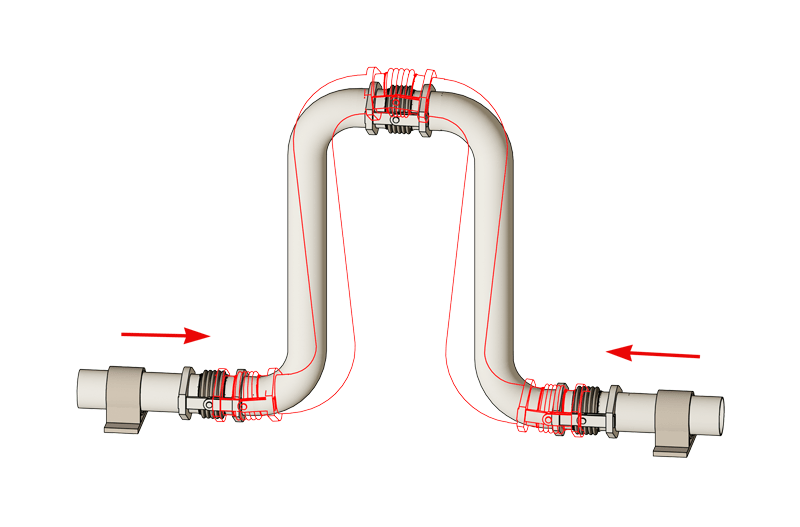

PVC pipe categorizes as a flexible conduit because it can deflect at least 2% without bursting or cracking. Technicians install PVC pipes at depths of more than 50 feet due to their flexibility. As the world changes and settles beneath the weight of fill material, SDR flexes. There are fewer breaks and a higher flex tolerance with the SDR design versus the SCH series.

Application

SDR 11 and SDR 13.5 are solid-wall pipes used in general-purpose outdoor applications like optical fiber, communication cable raceways, and drainage applications. It has a formidable solid wall AND a smooth, ribbed, low friction interior. These pipes provide some advantages, including the ability to be trenched or directionally drilled. This eliminates bends or elbows and increases availability via large master reels. Ultimately fewer joints result in increased integrity.