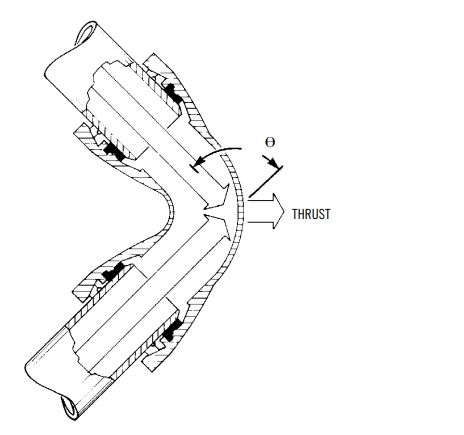

A restrained joint pipe serves to prevent separation of joints on a pressurized pipeline due to thrust forces. Generally, in a straight pipe section, hydrostatic forces balance themselves out. Whenever there are changes in pipeline direction such as bends, tees, or reducers, unbalanced thrust forces become present in the line. As a result, there is movement in the line, which could result in disconnection at joints. Thus, highlighting the need for a restrained joint or some other means to counterbalance these forces.

In this article, we review how a restrained joint pipe operates, compare it vs a thrust block, as well as vs a mechanical joint.

How a Restrained Joint Pipe Operates

All pipelines in operation experience loading depending on these conditions: size of pipe, depth of cover, design pressure, trench type, and soil conditions. However, the single most important contributor to loading is the type of fitting in use. The presence of fittings signifies a change in flow direction. When this change occurs there are forces that tend to separate the fitting and other joints at both sides – before and after the fitting. So, there is need to keep this assembly together, which is the job of a restrained joint pipe.

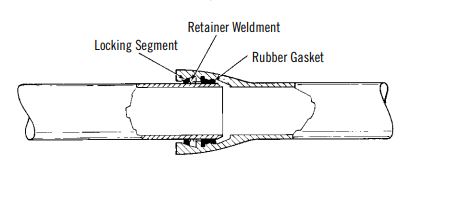

Various equipment manufacturers have unique features in their restrained joint pipes, however, they have similar functionality. Generally, they consist of a gasket, retainer weldment, and locking segment. The gasket often has teeth-like stainless steel segments that dig into the pipe for a secure connection. Together with other parts of the device, the gasket prevents axial movement and distributes the load to the surrounding soil via the lengths of restrained pipe. Typically, soils with higher friction angles and bearing capacity require shorter lengths of restrained pipe. When using this device, some key things to note are:

- Do not rotate the pipe joint to avoid damage to the fitting.

- Their use is not recommended surface use such as bridges, because potential vibrations could be detrimental.

Restrained Joint Pipe vs Thrust Block

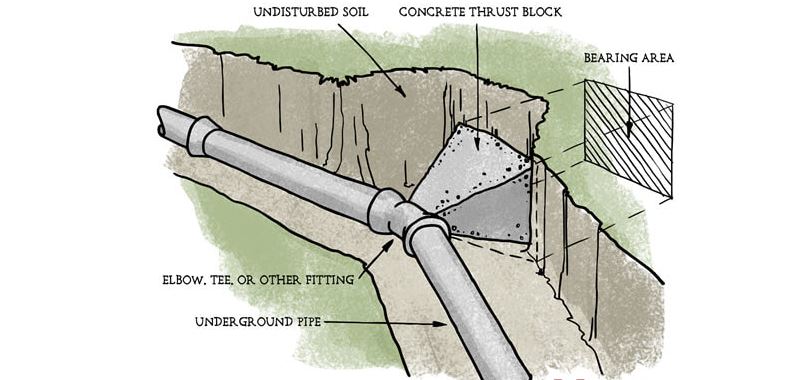

A thrust block is a concrete block put at pipe bends to prevent movement and separation by transferring loads to the undisturbed soil. For several years, it was the default means of resisting thrust forces in underground distribution systems, because of the perception that it is easy to use. However, it has several limitations, which makes restrained joint pipe a preferable option.

Cost Effectiveness

One of the reasons that thrust blocks were the go-to option for many projects is the view that it is cheap. When all the costs including labor, forming time, and waiting for curing are put together, it could exceed alternatives such as a restrained joint pipe.

Space Limitations

The effectiveness of thrust blocks largely depends on its size. In applications where the space is not adequate, thrust blocks may not be large enough to counterbalance the incident forces.

Soil Limitations

Another factor that influences the effectiveness of a thrust block is the kind of surrounding soil. If the bearing capacity of the soil is low, then the thrust block needs to be larger. So, areas with very poor bearing capacity such as swampy lands or marshes require thrust blocks that are so large that it may not be feasible.

Difficulty for Future Excavations

The use of thrust blocks in any application could be detrimental to future projects within the vicinity. Because, these concrete blocks transfer loads to the surrounding soil, removal of this soil could cause the pipe joint to fail. As a result, there is need for proper planning at the design stage that considers future expansion of the facility.

Safety Concerns

When installing large thrust blocks, it is necessary to leave the trench open for the curing of concrete. But these open trenches constitute a hazard and there could be prohibitions on them in some areas from safety regulatory authorities.

Restrained Joint Pipe vs Mechanical Joint

Similar to a restrained joint pipe, a mechanical joint provides a watertight seal at pipe connections. The difference between them lies in their restraining capabilities. Generally, a mechanical joint has two types of glands which are the standard gland and retainer gland. The standard gland provides the watertight seal typically up to 350 psi but will not prevent longitudinal separation of pipes beyond 50 psi. Whereas the retainer gland provides the necessary longitudinal restraint. In some applications, a standard gland can be used alongside a thrust block to achieve longitudinal restraint.