A 2-digit suffix is used by the IP (Ingress Protection) enclosure system to identify the level of ingress protection for enclosures. The IP65 certification indicates the device has the highest level of dust protection and is able to withstand low-pressure water jets from all directions, whereas the IP45 rating protects from tools and small wires larger than 1 millimeter and protected from low-pressure water jets from any direction. Learn about the IP protection system, the differences between the IP45 and IP65 ratings, and common IP applications in this article.

IP Protection System

The IP rating is an international standard. It determines the degree of protection or sealing efficacy in enclosures against the infiltration of objects, water, dust, and contact. Also, it is compliant with European Standard EN 60529.

Products are noted by the initials IP (Ingress Protection), followed by two digits and an optional letter in the IP code. The two digits denote the level of intrusion protection versus solids and liquids. The optional letter notes the product’s resistance to pressure.

IP Ratings – Intrusion Protection

| Level | Intrusion Protection |

|---|---|

| X | No protection. |

| 1 | Protection from a large part of the body such as a hand (but no protection from deliberate access); from solid objects greater than 50mm in diameter. For example, accidental touch by hands. |

| 2 | Protection against fingers or other objects not greater than 80mm in length and 12mm in diameter. For example, fingers. |

| 3 | Protection from entry by tools, wires, etc, with a diameter of 2.5 mm or more. For example, tools, and wires. |

| 4 | Protection against solid objects larger than 1mm. For example, wires, nails, screws, larger insects, and other potentially invasive small objects such as tools/small, etc. |

| 5 | Partial protection against dust that may harm equipment. |

| 6 | Totally dust-tight. Full protection against dust and other particulates, including a vacuum seal, tested against continuous airflow. |

IP ratings – Moisture Protection

| Level | Moisture Protection |

|---|---|

| X | No protection. |

| 1 | Protection against vertically falling droplets, such as condensation. ensuring that no damage or interrupted functioning of components will be incurred when an item is upright. |

| 2 | Protection against water droplets deflected up to 15° from vertical |

| 3 | Protected against spray up to 60° from vertical. |

| 4 | Protected against water splashes from all directions. Tested for a minimum of 10 minutes with an oscillating spray (limited ingress permitted with no harmful effects). |

| 5 | Protection against low-pressure jets (6.3 mm) of directed water from any angle (limited ingress permitted with no harmful effects). |

| 6 | Protection against direct high-pressure jets. |

| 7 | Protection against full immersion for up to 30 minutes at depths between 15 cm and 1 meter (limited ingress permitted with no harmful effects). |

| 8 | Protection against extended immersion under higher pressure (i.e. greater depths). Precise parameters of this test will be set and advertised by the manufacturer and may include additional factors such as temperature fluctuations and flow rates, depending on equipment type. |

| 9 | (K): Protection against high-pressure, high-temperature jet sprays, wash-downs, or steam-cleaning procedures – this rating is most often seen in specific road vehicle applications (standard ISO 20653:2013 Road Vehicles – Degrees of protection). |

IP45 vs. IP65 Difference

Water protection for IP45 vs IP65 is the same (5). The differences lie in the dustproof grade number (4 vs. 6).

| Rating | Difference | Similarities |

|---|---|---|

| IP45 | Protected from tools and small wires greater than 1 millimeter. | Protected from low-pressure water jets from any direction. |

| IP65 | Protected from total dust ingress. | Protected from low-pressure water jets from any direction. |

Common IP Applications

The universal IP rating system gives buyers confidence that they can use products in certain environments. For example, the term ‘waterproof’ doesn’t provide a clear definition of where and to what extent an item can resist moisture ingress. Therefore, an IP rating provides a far more specific account.

Protective IP cases may apply to lighting, controllers, electric instruments, power supply, industrial camera housings, desktop electronics, and measuring/control equipment, to name a few. Instrument applications such as volt-meters, digital thermometers, and flow readers are also common. Additionally, electrical motors often bear the IP designation.

IP-rated enclosures compete in the industrial market with the NEMA (National Electrical Manufacturers Association) designation.

Common IP45 Applications

An IP45 enclosure frequently provides resistance protection for electronic systems or components that may be susceptible to ingress from less obvious sources of moisture or particulates, such as condensation, steam, accumulating dust in hard-to-reach areas, and corrosion or chemical attack if the enclosure is to be placed in any type of demanding industrial environment.

A waterproof LED switching power supply in an aluminum enclosure provides one such example. A power supply for bathroom lights or outdoor advertising can afford to accumulate a fairly large amount of dust, thus the fairly permissible IP45 rating can suffice.

Common IP65 Applications

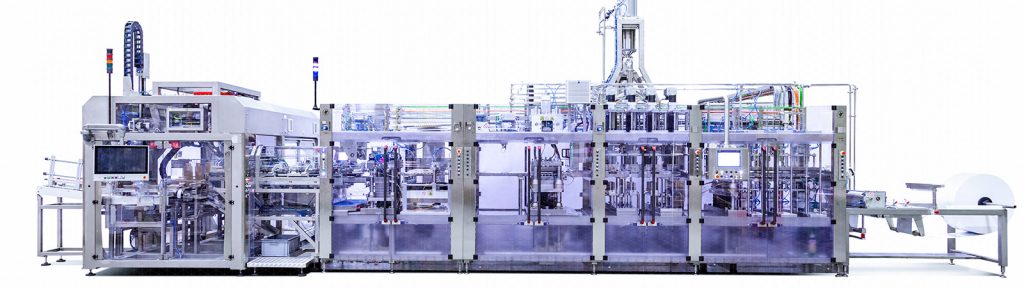

Applications for such drives with an IP65 rating are numerous. The form, fill, and seal (FFS) machines that dispense and seal items; the liquid dispensing and pumping applications in medical and life-science devices; and printing and labeling equipment are some examples. Barcode and labeling uses for medical device tracking and traceability 3D printers, and machine tools that use waterjet cutting, laser cutting, and tool changers provide some other uses.

IP45 VS. IP65 – Which to Choose?

The choice between IP45 vs. Ip65 boils down to a singular factor: how much dust can the enclosure tolerate?

For choices where dust protection is important, IP65 provides clearly superior protection.

The IP65 rating protects from total dust ingress vs. IP45 which protects from tools and small wires greater than 1 millimeter. In most cases, equipment designers simply opt for the total dust protection offered by IP65. This is reflected in IP65’s more common use vs. the IP45 enclosure.