API tanks see heavy use in the petroleum industry to store oil and other liquids. This article describes the features of an API tank, their construction, the different types, and associated maintenance requirements.

API Tank Features

The American Petroleum Institute, often referred to as API, dictates the construction requirements of an API tank. These requirements depend on tank size, location, and stored material characteristics. API standards dictate materials and processes used during construction and welding as well as testing procedures. Special elements such as nozzle reinforcement pads and structural supports are detailed in the API standards.

API tanks typically store oil, gasoline, and chemicals but may hold any other type of liquid such as water. Certain process media may require application of an internal coating. In contrast to ASME pressure vessels which primarily exist for processing, API tanks exist primarily for storage purposes.

API Tank Construction

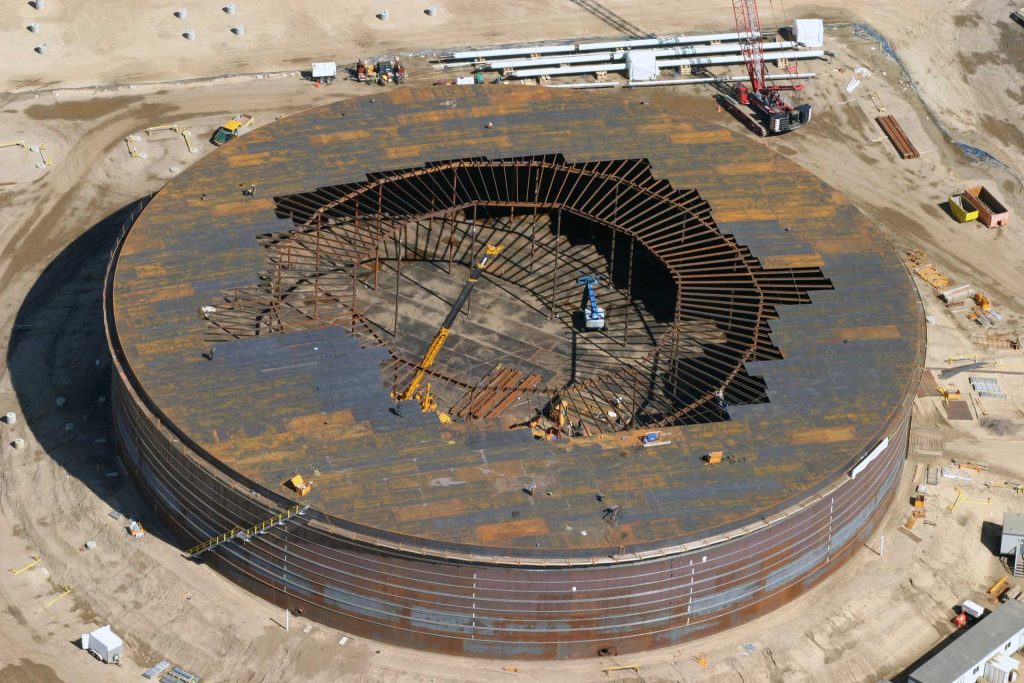

API tanks may also be referred to as AST, or above ground storage tanks. Due to the large nature of an API tank, construction typically takes place in the final location. API tank foundations comprise of concrete, crushed aggregate, or slab foundations. On-site, laborers field weld individual steel parts to comprise the tank’s exterior. After construction of the major exterior portions, assembly of liners, pumps, stairs, and other accessories begins.

API Tank Types

A litany of types exists for API storage tanks. There are twelve applicable API standards for tank use. A particular focus should be given to API-620 and API-650, the most commonly used types.

General Overview

| API Standard | Title | Details |

| API 620 | Design and Construction of Large, Welded, Low Pressure Storage Tanks | Guide for construction of tanks with internal pressures up to 15 psig. For large, field-assembled tanks used for storage of petroleum intermediates and petroleum products. |

| API 650 | Welded Steel Tanks for Oil Storage | Governs the construction of tanks storing hydrocarbon products at low operating pressure (up to 2.5 psig). |

| API 651 | Cathodic Protection for Above Ground Petroleum Storage Tanks | Provides guide on corrosion problems in above ground petroleum storage tanks and associated piping. Plus a description of two commonly used methods of providing cathodic protection against corrosion. |

| API 652 | Lining of Above Ground Petroleum Storage Tanks | Guidelines for limiting corrosion by lining the tank bottom. Guidelines are given regarding lining materials, their applications, inspection of tank bottom lining etc. |

| API 653 | Tank Inspection, Repair, Alteration, and Reconstruction | Guideline for inspection, repair, alteration, and reconstruction of above ground hydrocarbon and chemical storage tanks, made of steel. Minimum requirements for maintaining the integrity of welded or riveted, non-refrigerated, atmospheric, above-ground storage tanks, are discussed. |

| API 2000 | Venting Atmospheric and Low-Pressure Storage Tanks | Guide for normal and emergency vapor venting requirements for above ground petroleum and petroleum product storage tanks, above ground and underground refrigerated storage tanks. The tanks discussed in the document are designed for low pressures ranging from full vacuum through 15 psig. |

| API 2015 | Cleaning Petroleum Storage Tanks | Guide for preparing, emptying, isolating,ventilating, atmospheric testing, cleaning, entering into, hotwork and recommissioning activities in, on and around atmospheric and low-pressure (up to 15 psig) above ground storage tanks containing flammable, combustible or toxic materials. |

| API 2517 | Evaporating Losses from External Floating Roof Tanks | Guide for estimating the total evaporation losses or atmospheric hydrocarbon emissions from external floating roof tanks containing multicomponent hydrocarbon mixtures or single component storage stocks. |

| API 2519 | Evaporating Losses from Internal Floating Roof Tanks | Summary of performances of internal floating covers to prevent evaporation losses. Effects of internal floating covers on tank operation as well as the provisions for gaging, sampling, and temperature reading are described in the document. |

| API 2350 | Overfill Protection for Petroleum Storage Tanks | Covers overfill protection for all above ground storage tanks in petroleum facilities, including refineries, terminals, bulk plants, and pipeline terminals that receive Class I (flammable) or Class II (combustible) liquids. |

| API 2550 | Measurements and Calibration of Petroleum Storage Tanks | Procedures for calibrating upright cylindrical tanks which are larger than a drum or a barrel. Procedures for making measurements are discussed in Part I of the document and methods of calculating the tank volume are given in Part II. |

For generalized use, two main types of API tanks: API 620, API 650. API tanks may also be categorized by the roofing used in their construction.

API 620

API 620 tanks see large welds and applications for highly pressurized fluids like natural gas and provide storage at relatively lower temperatures. They require either an elevated or flat bottom with a tank minimum thickness of 3/16 of an inch. Typically the 620’s material of construction is a steel alloy. The API 620 fits products that require high internal pressure such as liquified natural gas (LNG) and cryogenic tanks. This type of tank can store any liquid.

API 650

Another tank type, API 650, sees heavy use in the oil and gas industry. Requirements are to be above ground and are possess a minimum thickness of 3/16 of an inch. Materials of construction are typically carbon steel, austenitic duplex stainless steel, and aluminum. They are ideal for higher temperature and low-pressure storage as opposed to that of the API 620.

API Tank Roofing

API tanks can have a variety of roof types. The type of roofs include fixed-roof, external floating roof, internal floating roof tanks, and domed external floating roof.

Fixed roof tanks are the most common tank type. They feature a closed and completely welded roof. Roof designs are usually cone or dome-shaped. Usually, these tanks will also have a valve used to control and maintain the internal pressure of the tank.

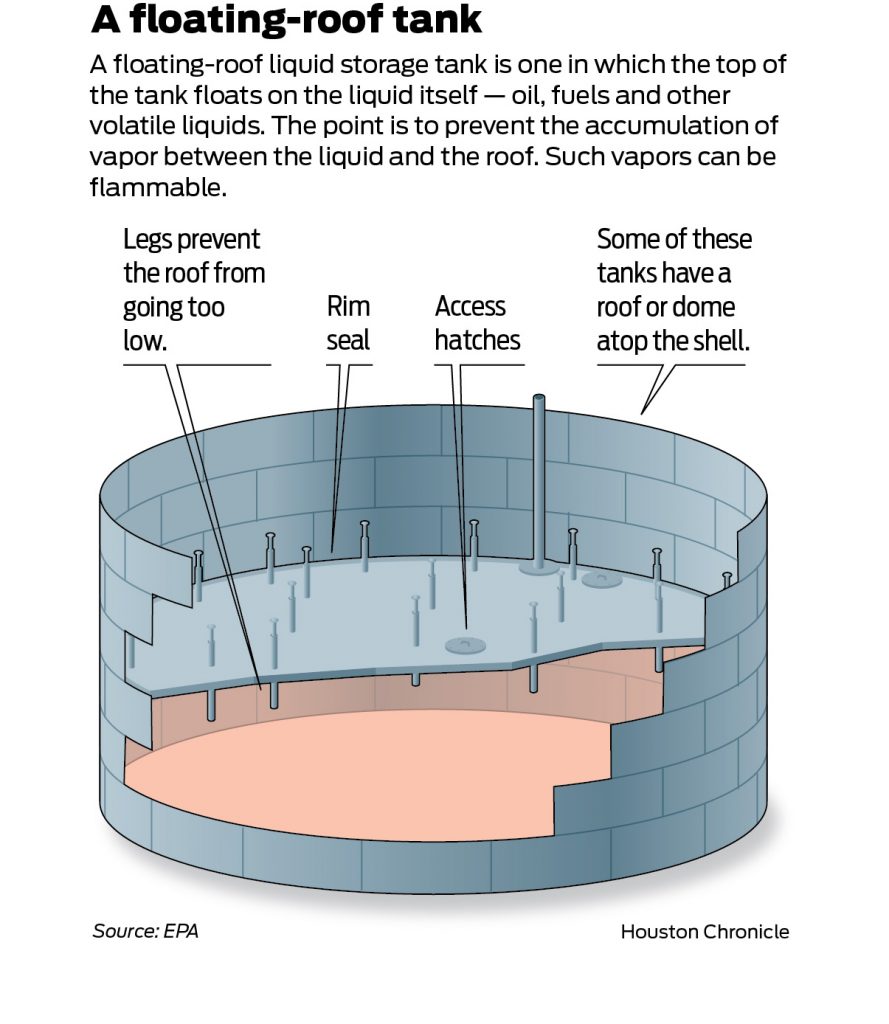

External floating roof tanks feature a cylinder with an open-top while the roof floats on the surface of the stored liquid. This roof type provides cost-effectiveness and protection from fluid discharge. A rim sealing system creates a secure seal with the walls of the tank.

Internal floating roof tanks combine the mechanisms of a fixed and external floating roof. It is essentially a closed top cylinder with an internal floating roof.

The domed external floating roof combines an external floating roof with a domed fixed roof. The dome aids in blocking wind on the internal components of the tank.

Tank Maintenance

Maintenance of an API tank is crucial to ensuring proper functioning, personnel safety, and environmental safety. Routine inspection ensures welds are intact and undamaged. Usually, visual inspection is appropriate, but other methods of NDE may be used. The type of inner lining of the tank determines the damage repair process. Ideally, damage repairs occur prior to leakage. Leaks can be harmful to the environment and to personnel around the tank especially if the tank holds any harmful chemicals. Proper monitoring of the internal pressure and temperature of the tanks are also an essential part of maintaining the integrity and safety of an API tank.